Heavy oil hydrogenation upgrading process for coupled cracking and reforming hydrogen production

A technology of hydrogenation upgrading and reforming to produce hydrogen, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problems of harsh hydrogenation reaction conditions, carbon deposition and deactivation of catalysts, and light components of oil products. Low-level problems, to achieve the effects of saving transportation and storage costs, high efficiency of hydrogenation and upgrading, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

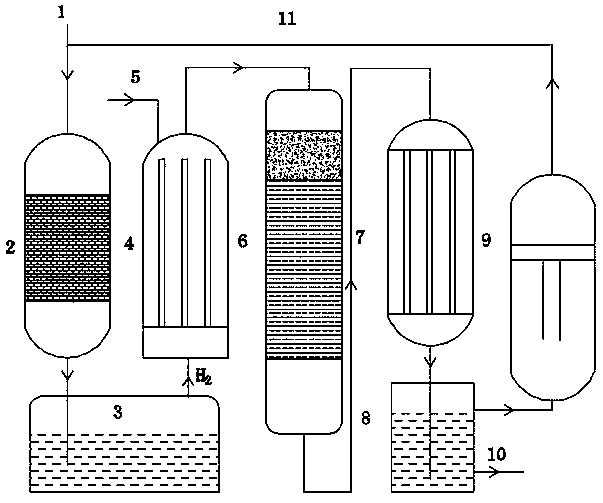

[0039] This example is the application of catalytic hydrogenation upgrading process for Fushun oil shale pyrolysis oil, such as figure 1 As shown, the design of heavy oil hydrogenation upgrading process includes: methane and water raw material inlet 1, methanol reforming reactor 2, gas-liquid separation device 3, heavy oil gasifier 4, heavy oil inlet 5, fixed bed reaction Device 6, quenching reactor 7, product oil tank 8, hydrogen pressurizer 9, upgrading pyrolysis oil outlet 10. Methanol and water enter the methanol reformer 2 according to a certain ratio, and the mixed gas of hydrogen, carbon dioxide, methanol and water is prepared through the methanol reforming catalyst bed 3; the mixed gas of hydrogen and carbon dioxide passes through the gas-liquid separation device, and passes through the heavy The oil gasification furnace 4 enters the fixed bed reactor 6 and provides pressure for the reaction system; when the pressure in the reactor system reaches the required value, th...

Embodiment 2

[0042] This embodiment is the application of the catalytic hydrogenation upgrading process of residual oil pyrolysis oil, such as figure 1 As shown, the heavy oil hydrogenation upgrading process design includes methanol feedstock inlet 1, methanol cracking reactor 2, gas-liquid separation device 3, heavy oil gasifier 4, heavy oil inlet 5, fixed bed reactor 6, Quenching reactor 7, product oil tank 8, hydrogen pressurizer 9, upgrading pyrolysis oil outlet 10. Methanol and water enter the methanol reformer 2 according to a certain ratio, and the mixed gas of hydrogen, carbon monoxide, methanol and water is prepared through the methanol reforming catalyst bed 3; the mixed gas of hydrogen and carbon monoxide passes through the gas-liquid separation device, and passes through the heavy The oil gasification furnace 4 enters the fixed bed reactor 6 and provides pressure for the reaction system; when the pressure in the reactor system reaches the required value, the pyrolysis oil raw m...

Embodiment 3

[0045] This example is the application of catalytic hydrogenation upgrading process for oil sand pyrolysis oil, such as figure 1 As shown, the design of heavy oil hydrogenation upgrading process includes methane raw material inlet 1, methane reforming reactor 2, gas-liquid separation device 3, heavy oil gasifier 4, heavy oil inlet 5, fixed bed reactor 6 , a quenching reactor 7, a product oil tank 8, a hydrogen pressurizer 9, and an outlet 10 for upgrading pyrolysis oil. Methane and water enter the methane reformer 2 according to a certain ratio, and the mixed gas of hydrogen, carbon monoxide, methane and water is prepared through the methane reforming catalyst bed 3; the mixed gas of hydrogen and carbon monoxide passes through the gas-liquid separation device, and passes through the heavy The oil gasification furnace 4 enters the fixed bed reactor 6 and provides pressure for the reaction system; when the pressure in the reactor system reaches the required value, the pyrolysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com