L-proline immobilized temperature-sensitive hairy polymer microsphere and preparation method thereof

A proline temperature-sensitive, polymer technology, applied in the preparation of organic compounds, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of large amount of hybrid microspheres, L - Problems such as low proline immobilization amount achieve short catalytic time, increase rate and selectivity, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

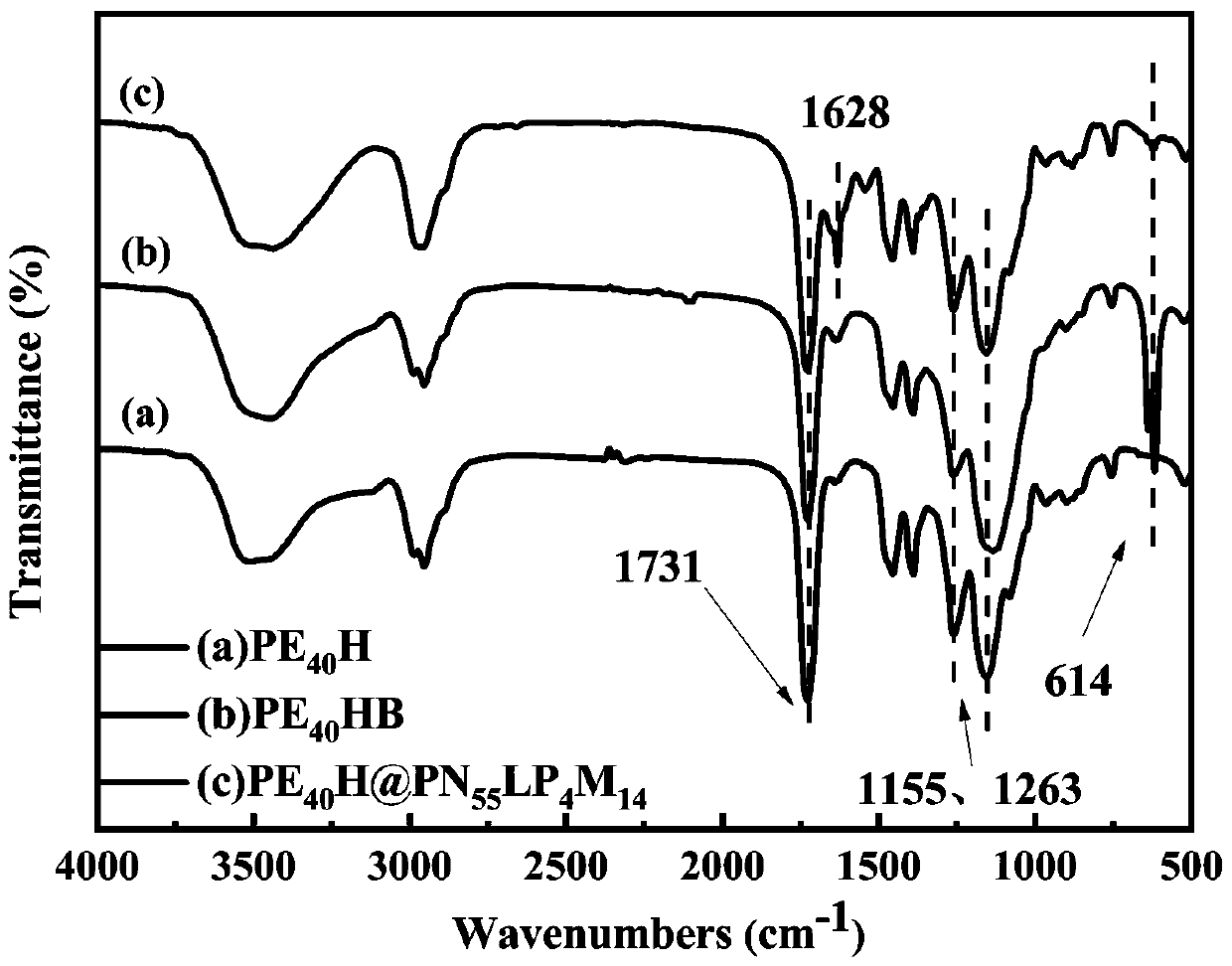

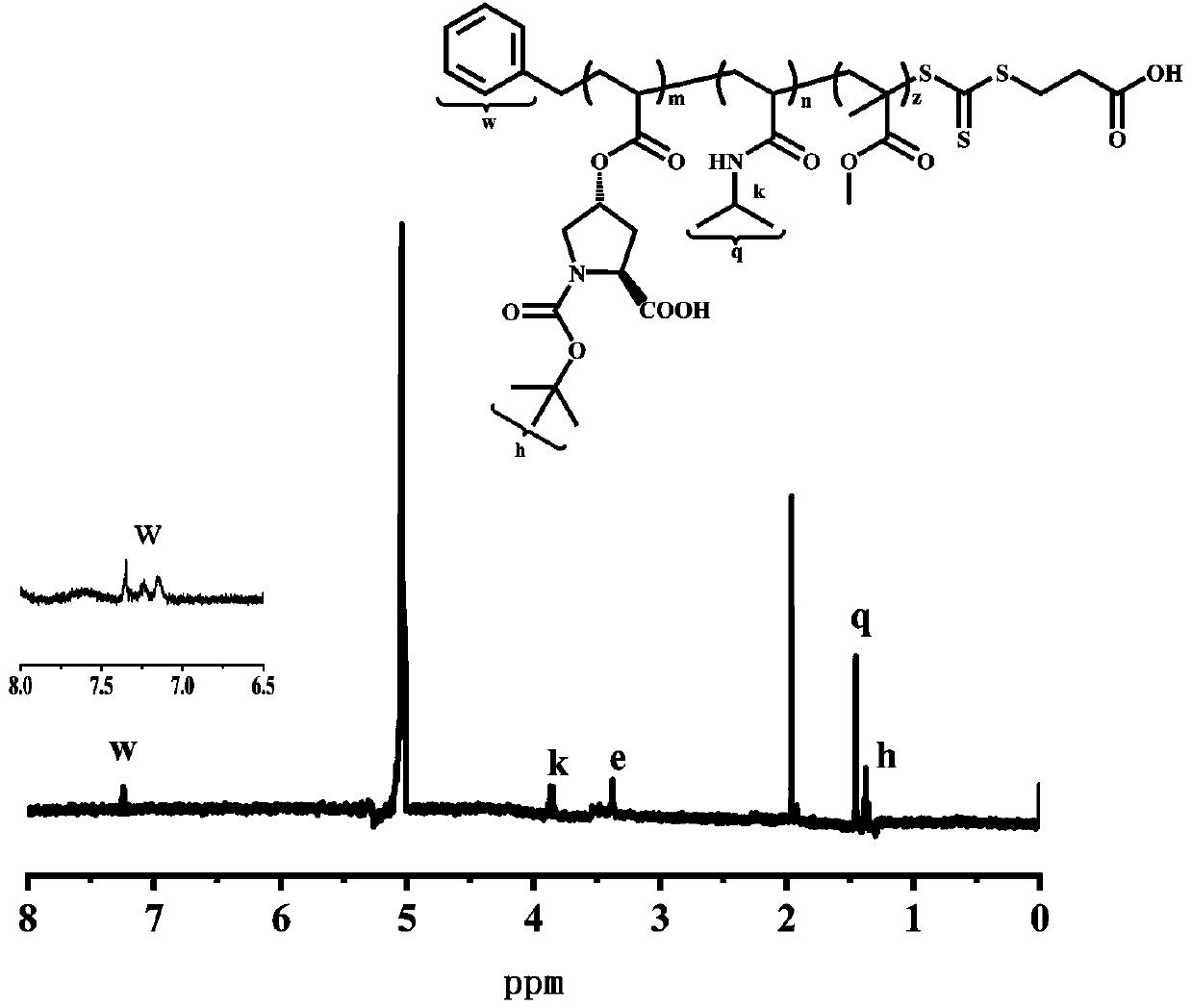

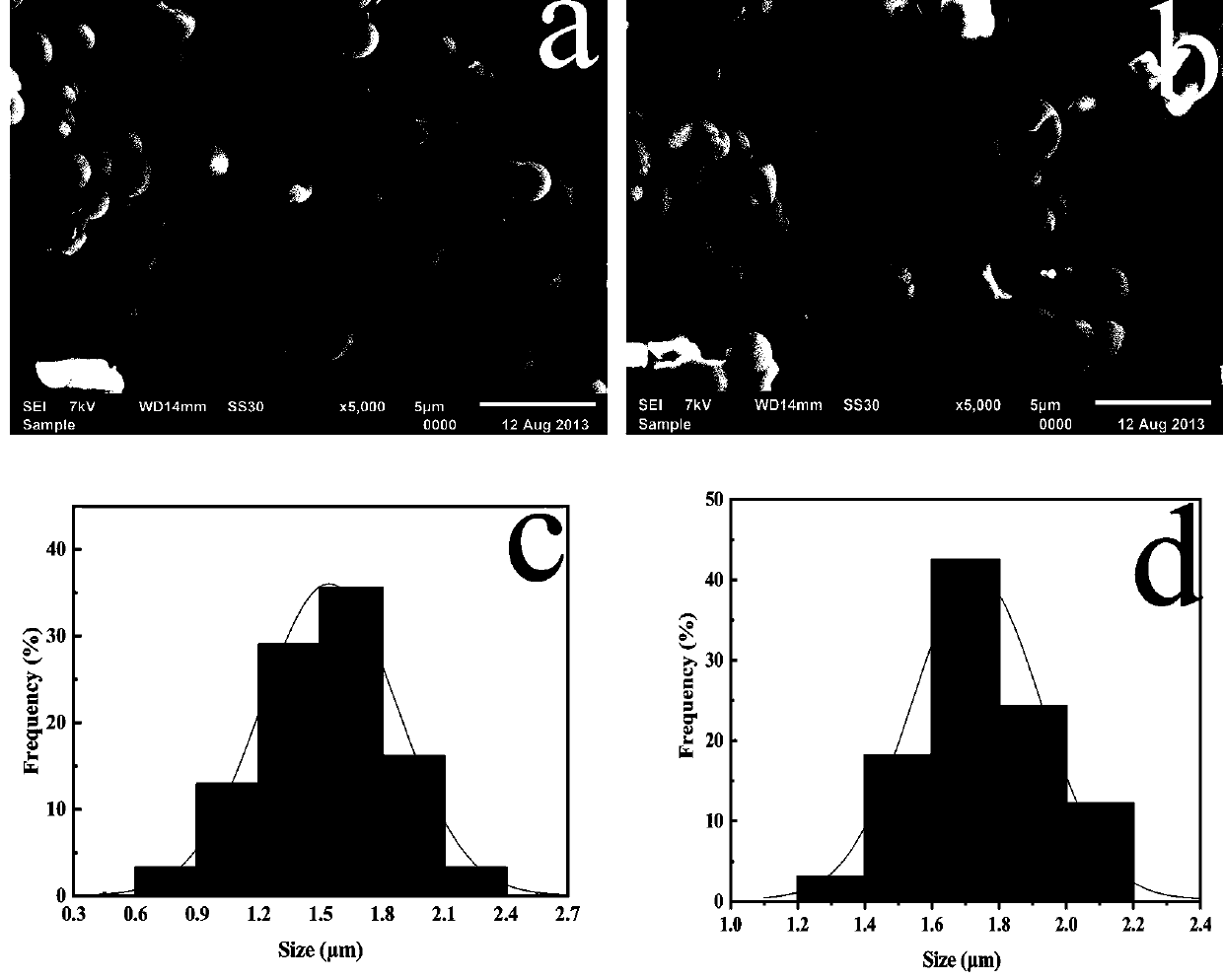

[0034] Measure monomer HEMA 1.2mL, EGDMA 0.8mL, and initiator AIBN 0.04g (0.244mmol), add them together into a 250mL round bottom flask, continue to add 80mL acetonitrile and stir until the mixture is uniform. Install a fractionation column, a condenser and a receiving flask, heat the round-bottomed flask slowly to bring the temperature of the reaction system to boiling within 25 minutes, control the time to distill 40 mL of acetonitrile within 1.5 hours, and then end the reaction. The product was separated by centrifugation, washed 3 times with ethanol, and dried to obtain a white powdery solid, that is, P(EGDMA) containing hydroxyl groups on the surface. 40 - co -HEMA) microspheres, referred to as PE 40 H.

[0035] Weigh PE 40 Add 0.3g of H, 0.272g (0.001mol) of BSPA, and 0.252g (0.002mol) of DMAP into a round bottom flask filled with 10mL of dichloromethane, and let stand in an ice-water bath for 20min. Weigh 0.036g (0.018mmol) of DCC in the above-mentioned round bottom...

Embodiment 2

[0045] Measure 0.8mL of monomer HEMA, 1.2mL of EGDMA, and 0.04g (0.16mmol) of initiator ABVN, add them together into a 250mL round bottom flask, continue to add 80mL of methanol and stir until the mixture is uniform. Install a fractionation column, a condenser tube and a receiving flask, heat the round-bottomed flask slowly to bring the temperature of the reaction system to boil within 15 minutes, control the time to distill 40 mL of methanol within 1 hour, and then end the reaction. The product was separated by centrifugation, washed 3 times with ethanol, and dried to obtain a white powdery solid, that is, P(EGDMA) containing hydroxyl groups on the surface. 60 - co -HEMA) microspheres, referred to as PE 60 H.

[0046] Weigh PE 60 Add 0.35g of H, 0.218g (0.6mmol) of DDMAT, and 0.384g (0.003mol) of DMAP into a round-bottomed flask filled with 20mL of dichloromethane, and let stand in an ice-water bath for 25min. Take DCC 0.042g (0.204mmol) in the above-mentioned round-botto...

Embodiment 3

[0051] Measure monomer HEMA 0.4mL, EGDMA 1.6mL, and initiator AIBN 0.04g (0.244mmol), add them together into a 250mL round bottom flask, continue to add 80mL tetrahydrofuran and stir until well mixed. Install a fractionation column, a condenser and a receiving flask, heat the round-bottomed flask slowly to bring the temperature of the reaction system to boil within 30 minutes, control the time to distill 40 mL of tetrahydrofuran within 2 hours, and then end the reaction. The product was separated by centrifugation, washed 3 times with ethanol, and dried to obtain a white powdery solid, that is, P(EGDMA) containing hydroxyl groups on the surface. 80 - co -HEMA) microspheres, referred to as PE 80 H.

[0052] Weigh PE 80 Add 0.4g of H, 0.272g (0.001mol) of BSPA, and 0.48g (0.004mol) of DMAP into a round-bottomed flask filled with 25mL of dichloromethane, and let stand in an ice-water bath for 30min. Weigh 0.053g (0.253mmol) of DCC in the above-mentioned round bottom flask, re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com