Preparation method of PDMS film with thermosensitivity

A thin-film, temperature-sensitive technology, applied in the field of preparation of PDMS thin films, can solve the problems of complex methods of temperature-sensitive thin films, poor oxidative photostability, reduced temperature-sensitive characteristics, etc., and achieves easy-to-master process, short time-consuming, and simple experimental equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

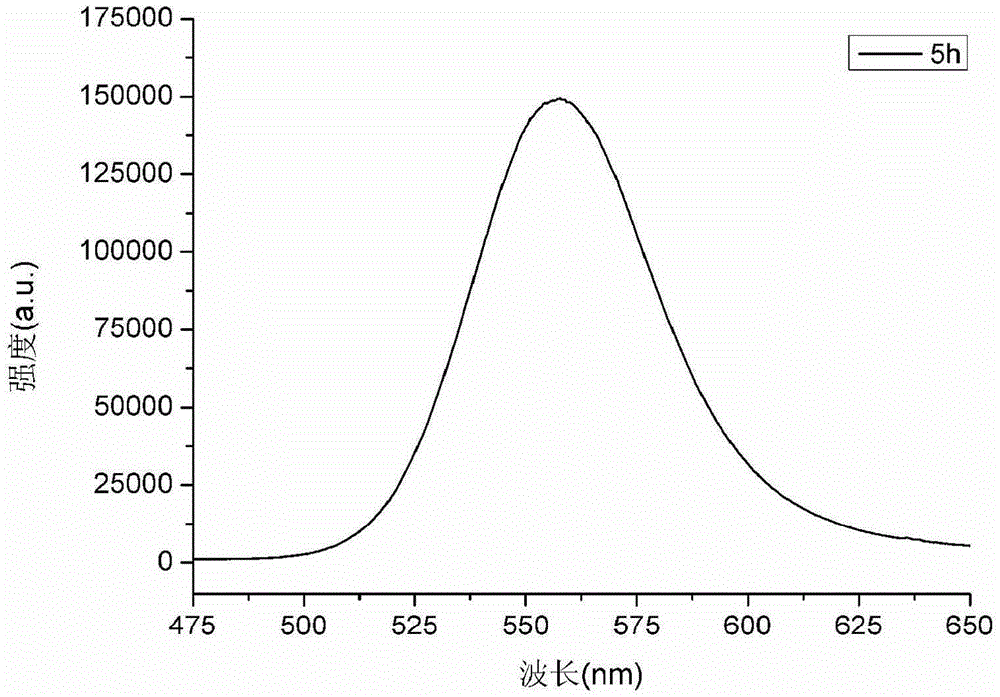

[0022] A method for preparing a PDMS film with temperature-sensitive properties, comprising the following steps:

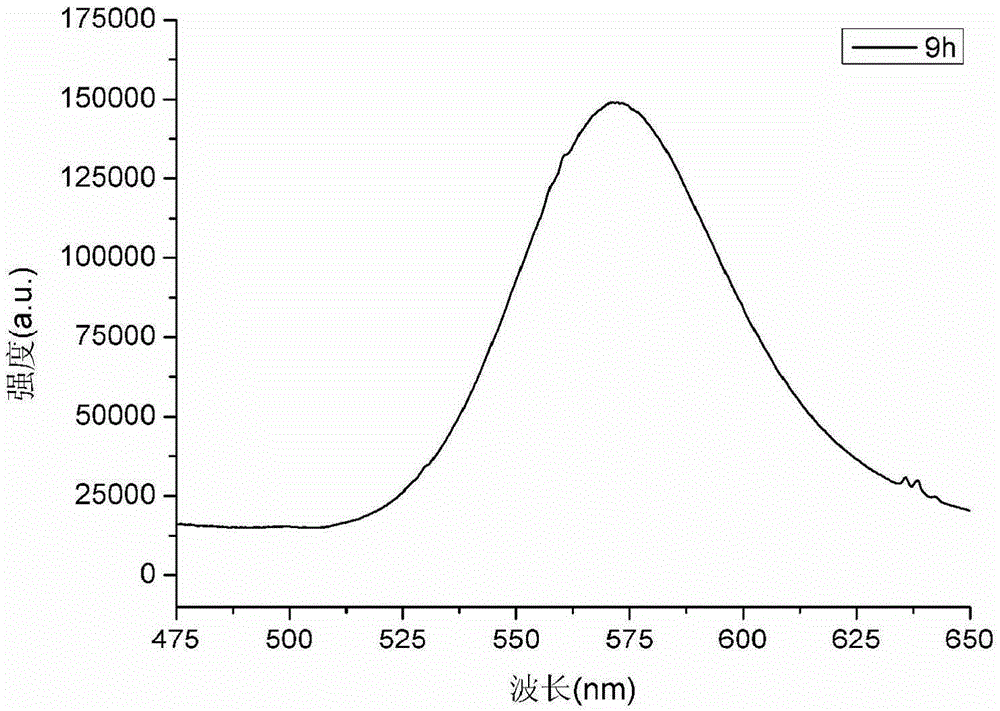

[0023] The first step, the preparation of temperature-sensitive cadmium telluride quantum dots: take 46mL ultrapure water and place it in a three-neck round bottom flask, deoxygenate with nitrogen gas for 30min by bubbling method, then add 0.04mol / L cadmium acetate aqueous solution, 0.01mol / L Potassium tellurite aqueous solution was added to 4mL according to the volume ratio of 1:1, followed by adding 400mg of sodium citrate, 100mg of mercaptosuccinic acid and 50mg of sodium borohydride to form a final precursor solution. Condensation and reflux reaction in an oil bath, by controlling the reaction time for 9 hours, temperature-sensitive cadmium telluride quantum dots were obtained;

[0024] The second step, the purification and redispersion of cadmium telluride quantum dots: the cadmium telluride quantum dots prepared in the first step are subjected to rotary eva...

Embodiment 2

[0028] A method for preparing a PDMS film with temperature-sensitive properties, comprising the following steps:

[0029] The first step, the preparation of temperature-sensitive cadmium telluride quantum dots: take 46mL ultrapure water and place it in a three-neck round bottom flask, deoxygenate with nitrogen gas for 30min by bubbling method, then add 0.04mol / L cadmium acetate aqueous solution, 0.01mol / L Potassium tellurite aqueous solution was added to 4mL according to the volume ratio of 1:1, and then 400mg of sodium citrate, 100mg of mercaptosuccinic acid and 50mg of sodium borohydride were added in sequence to form a precursor solution. Condensation and reflux reaction in an oil bath, by controlling the reaction time for 9 hours, temperature-sensitive cadmium telluride quantum dots were obtained;

[0030] The second step, the purification and redispersion of cadmium telluride quantum dots: the cadmium telluride quantum dots prepared in the first step are subjected to rot...

Embodiment 3

[0034] A method for preparing a PDMS film with temperature-sensitive properties, comprising the following steps:

[0035] The first step, the preparation of temperature-sensitive cadmium telluride quantum dots: take 46mL ultrapure water and place it in a three-neck round bottom flask, deoxygenate with nitrogen gas for 30min by bubbling method, then add 0.04mol / L cadmium acetate aqueous solution, 0.01mol / L Potassium tellurite aqueous solution was added to 4mL according to the volume ratio of 1:1, and then 400mg of sodium citrate, 100mg of mercaptosuccinic acid and 50mg of sodium borohydride were added in turn to form a precursor solution. Condensation and reflux reaction in an oil bath, by controlling the reaction time for 9 hours, temperature-sensitive cadmium telluride quantum dots were obtained;

[0036] The second step, the purification and redispersion of cadmium telluride quantum dots: the cadmium telluride quantum dots prepared in the first step are subjected to rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com