High-cohesiveness water-based PVDF slurry and preparation method and application thereof

A high-adhesive, water-based technology, applied to structural parts, non-aqueous electrolyte batteries, battery pack components, etc., can solve the problem of poor bonding between the composite diaphragm and the positive and negative electrodes of the battery, and the increase in the tortuosity of the aperture of the composite diaphragm , Inconsistent coating porosity and other problems, to achieve good adhesion, reduce liquid absorption rate, and improve battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

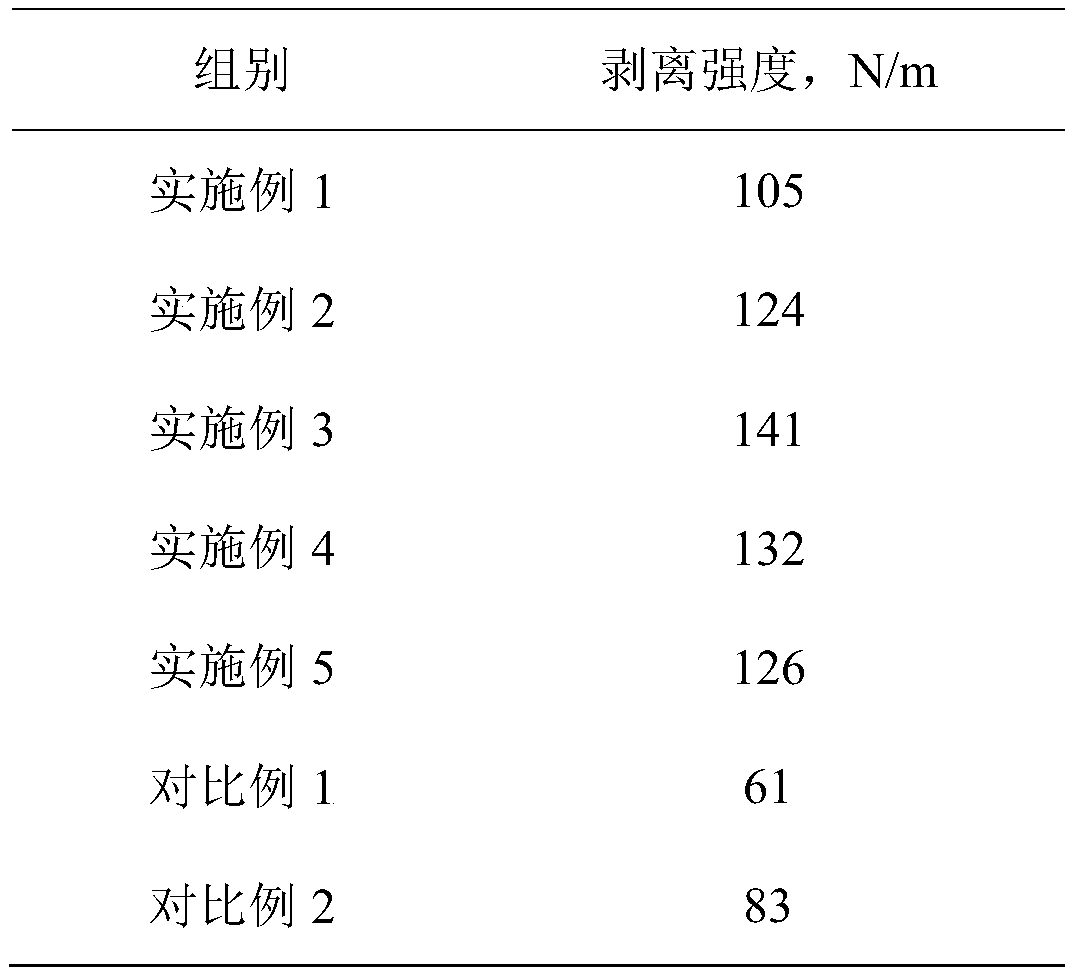

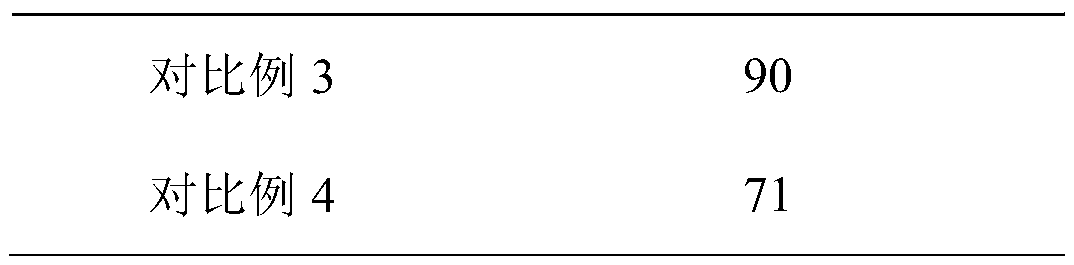

Examples

preparation example Construction

[0032] The preparation method of above-mentioned aqueous PVDF slurry, comprises the following steps:

[0033] S1. Add silicon carbide and dispersant to water, and ultrasonically disperse to obtain suspension A; S2. Add PVDF, anti-sedimentation agent, and defoamer to suspension A, stir at room temperature, and the stirring rate is 100-200r / min, the stirring time is 30-40min, to obtain the mixed solution B; S3, add the binder and wetting agent into the mixed solution B, and stir at room temperature to obtain a highly cohesive water-based PVDF slurry. The following examples and comparative examples adopt this method to prepare water-based PVDF slurry.

Embodiment 1

[0035] A highly cohesive water-based PVDF slurry, including the following raw materials in weight percentage: 7% sodium tripolyphosphate, 5% sodium alkylaryl sulfonate, 5% acrylic binder, 3% high-carbon alcohol fat Ester compound, 0.1% polyamide wax, 15% PVDF and 0.05% silicon carbide, the balance is water, the amount of added silicon carbide and the added amount of PVDF are 1:300 by mass ratio.

Embodiment 2

[0037] A highly cohesive water-based PVDF slurry, including the following raw materials in weight percentage: 6% sodium hexametaphosphate, 4% sodium butylnaphthalene sulfonate, 6% acrylic binder, 2% polyoxyethylene polyoxygen Propylene pentaerythritol ether, 0.5% polyamide wax, 20% PVDF and 0.2% silicon carbide, the balance is water, and the addition amount of the silicon carbide and PVDF is 1:100 by mass ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com