Light-driven oxygen production type corneal contact lens, preparation method and application thereof

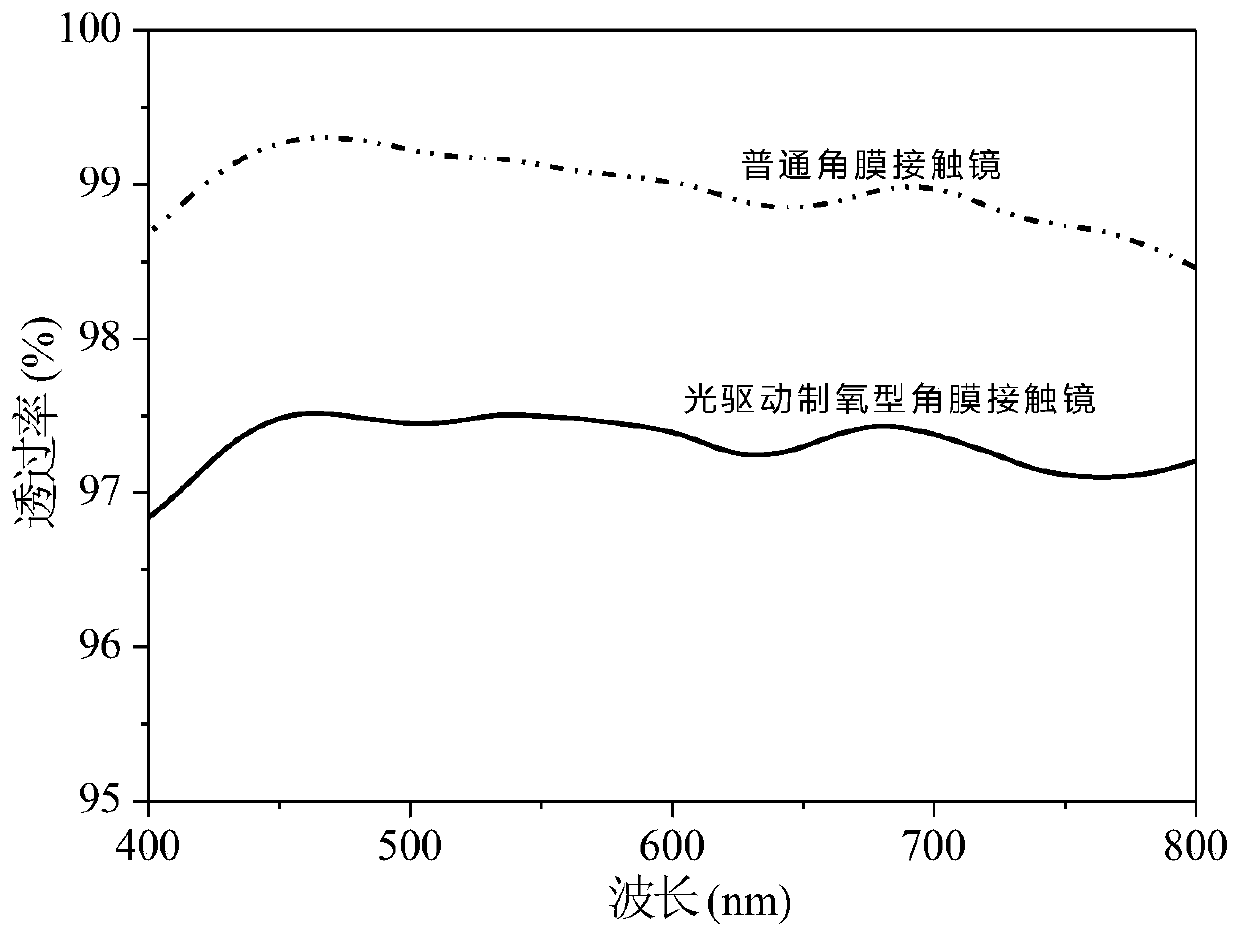

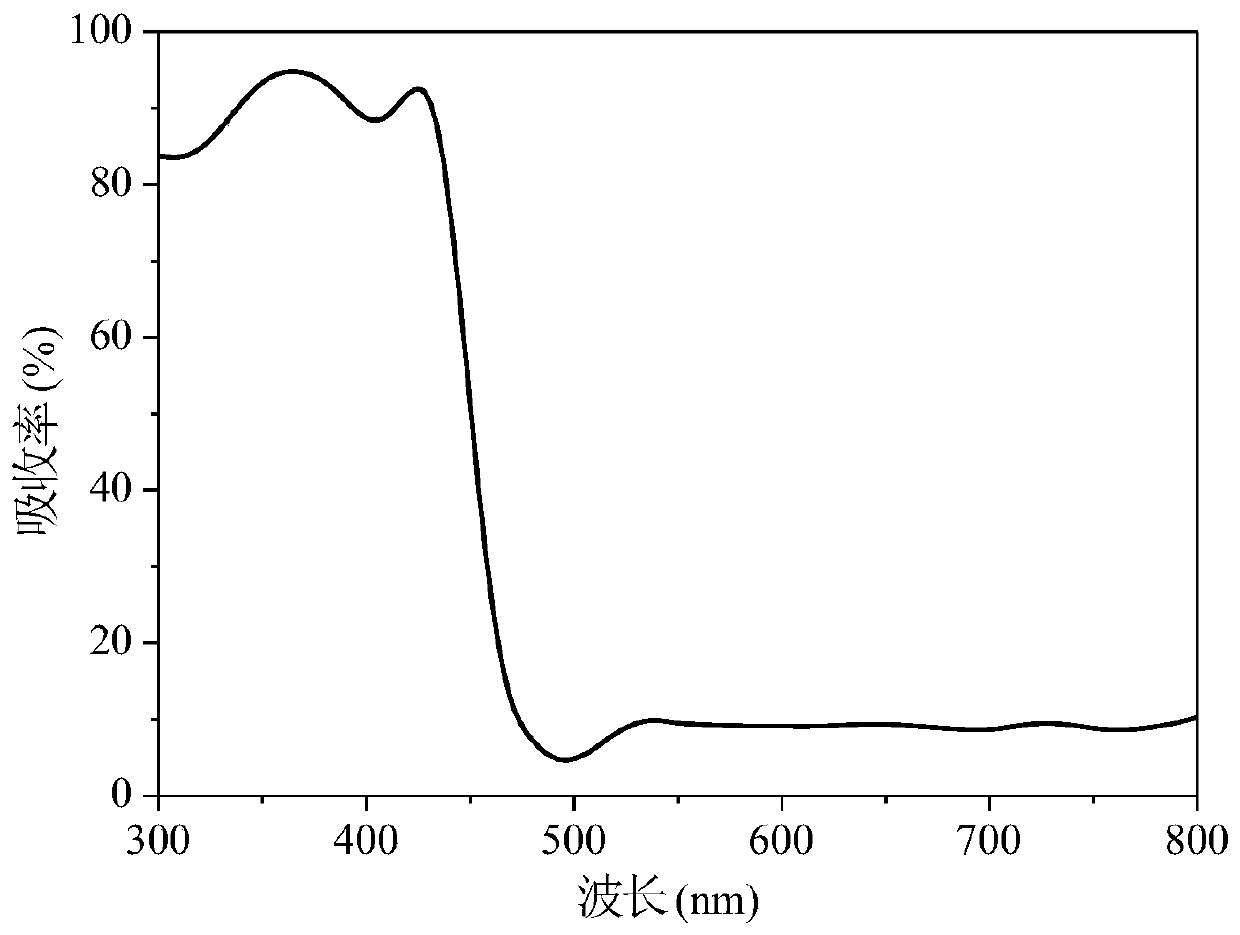

A contact lens and light-driven technology, which is applied in optics, optical components, glasses/goggles, etc., can solve the problem of limited use of ophthalmic lenses, achieve excellent control performance, improve wearing comfort, and improve biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) p-type semiconductor (copper bismuthate, CuBi 2 o 4 ), n-type semiconductor (bismuth vanadate, BiVO 4 ), passivation layer (magnesium oxide, MgO) target preparation:

[0051] The p-type semiconductor, n-type semiconductor, and passivation layer powder are used as raw materials, and ethanol is used as the medium. After the raw materials are wet ball milled for 12 hours, they are dried at 80°C and sintered by hot pressing to form a dense circular target.

[0052] (2) Preparation of central interlayer slurry:

[0053] The raw material of graphene slurry is ultrasonically dispersed in ethanol solvent according to the concentration of 1.0wt%.

[0054] (3) Preparation of flexible heterojunction electrodes:

[0055] The graphene center interlayer slurry was spin-coated on the surface of the polished silicon wafer, and dried at 100°C; the copper bismuthate, bismuth vanadate and magnesium oxide targets were respectively installed on the target position of the magnetron s...

Embodiment 2

[0064] (1) p-type semiconductor (copper bismuthate, CuBi 2 o 4 ; Cuprous oxide, Cu 2 O), n-type semiconductor (bismuth vanadate, BiVO 4 ;Titanium dioxide, TiO 2), passivation layer (aluminum oxide, Al 2 o 3 ) target preparation:

[0065] The p-type semiconductor, n-type semiconductor, and passivation layer powder are used as raw materials, and ethanol is used as the medium. After the raw materials are wet ball milled for 12 hours, they are dried at 80°C and sintered by hot pressing to form a dense circular target.

[0066] (2) Preparation of central interlayer slurry:

[0067] The graphene puree is ultrasonically dispersed in ethanol solvent according to the concentration of 2.0wt%.

[0068] (3) Preparation of flexible heterojunction electrodes:

[0069] The graphene center interlayer slurry is spin-coated on the surface of the polished silicon wafer, and dried at 100°C; the targets of copper bismuthate, cuprous oxide, bismuth vanadate, titanium dioxide and alumina are...

Embodiment 3

[0078] (1) p-type semiconductor (zinc oxide, ZnO), n-type semiconductor (bismuth vanadate), passivation layer (aluminum oxide, Al 2 o 3 ) target preparation:

[0079] The p-type semiconductor, n-type semiconductor, and passivation layer powder are used as raw materials, and ethanol is used as the medium. After the raw materials are wet ball milled for 12 hours, they are dried at 80°C and sintered by hot pressing to form a dense circular target.

[0080] (2) Preparation of central interlayer slurry:

[0081] The carbon nanotube slurry was ultrasonically dispersed in an ethanol solvent at a concentration of 2.0 wt%.

[0082] (3) Preparation of flexible heterojunction electrodes:

[0083] The carbon nanocenter interlayer slurry was spin-coated on the surface of the polished silicon wafer, and dried at 100°C; the zinc oxide, bismuth vanadate and aluminum oxide targets were respectively installed on the target position of the magnetron sputtering instrument; the spin-coated carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com