Corrosion early warning monitor based on weak accumulated current technology

A cumulative current, early warning and monitoring technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of high ability requirements of testing personnel, waste of resources, low precision, etc., to improve the anti-interference ability of the instrument, easy to use and carry , Wide compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

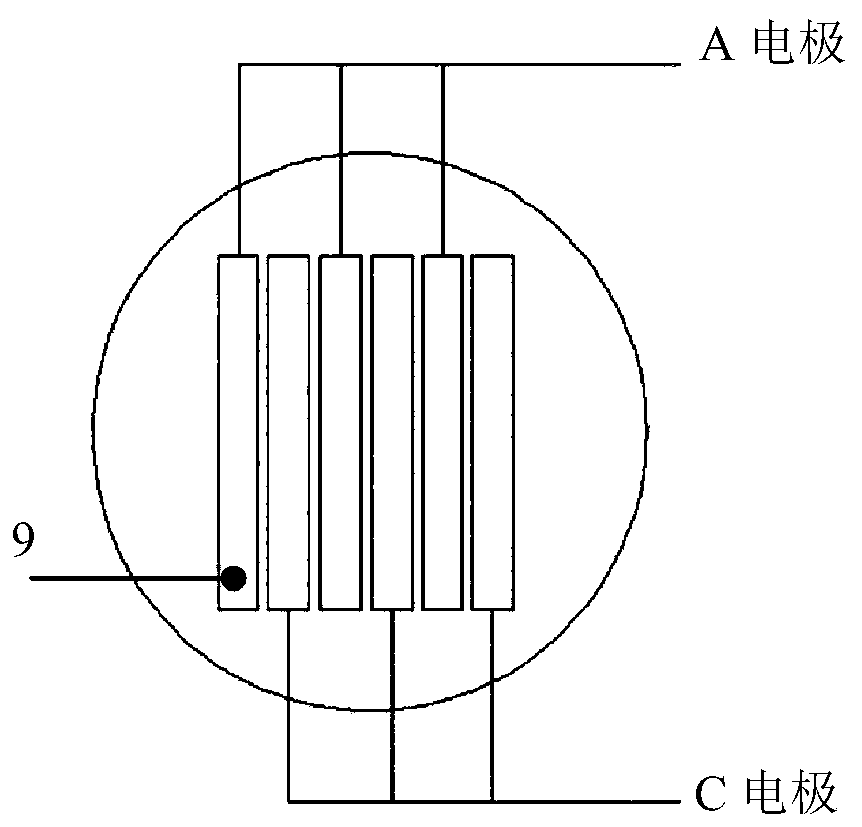

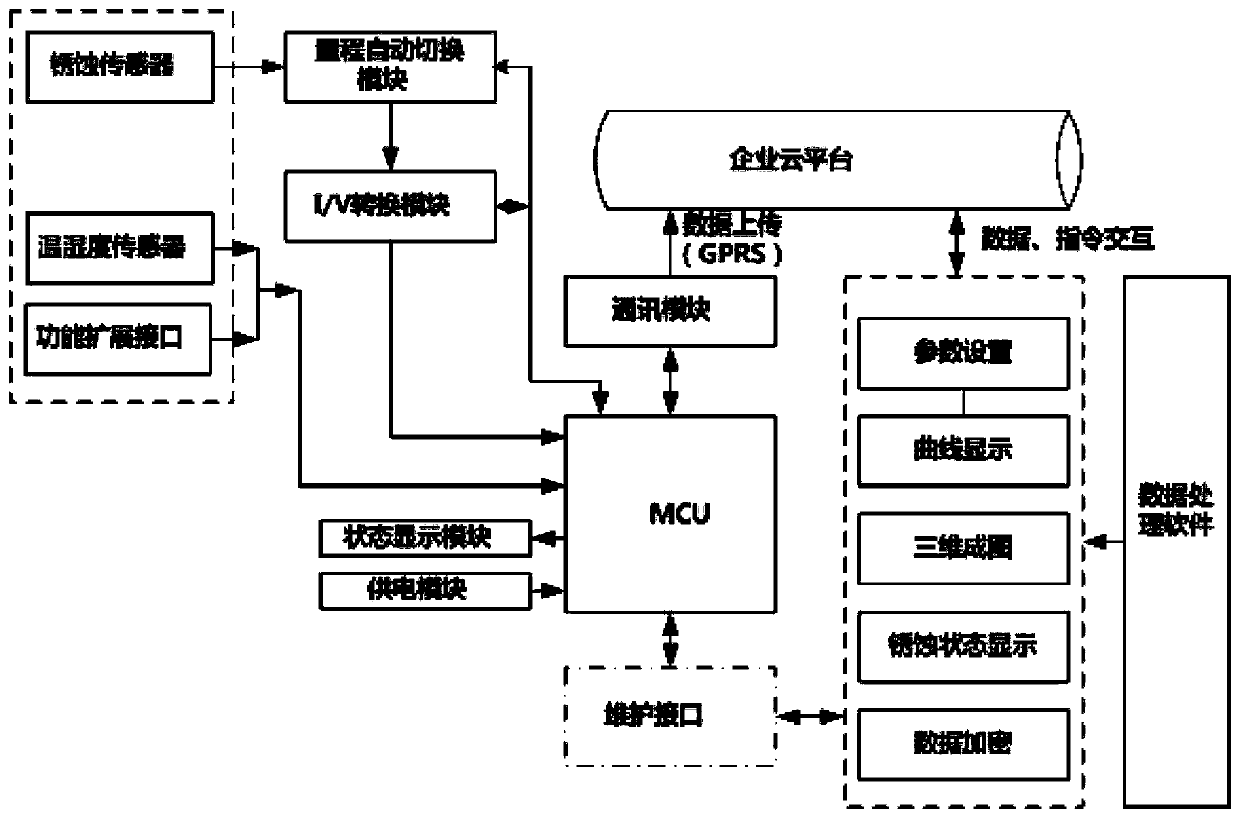

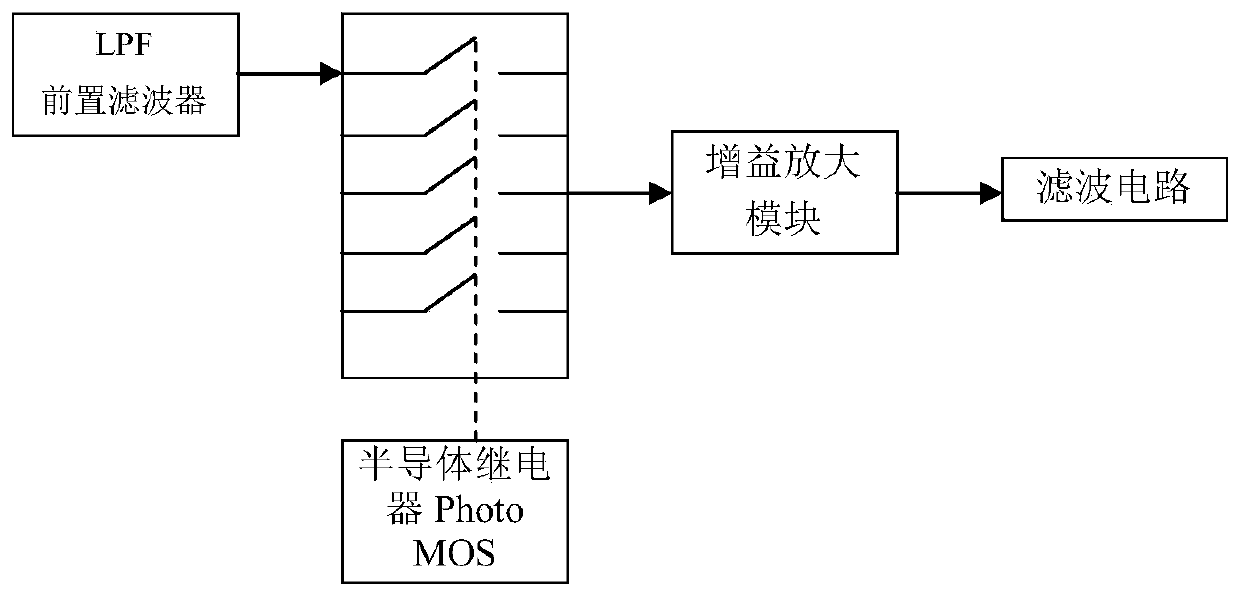

[0030] Such as figure 1 As shown, a corrosion early warning monitor based on weak cumulative current technology includes a corrosion sensor, a temperature / humidity sensor, a central processing unit, an automatic range switching module, an I / V conversion module, a status display module, a communication module and a power supply module. Among them, the control terminal of the central processing unit is connected with the automatic range switching module and the I / V conversion module respectively, and the signal collected by the rust sensor 1 enters the central processing unit through the automatic range switching module and the I\V conversion module successively, and the temperature / humidity sensor collects The signal of the central processor is directly output to the central processing unit; the communication terminal data of the central processing u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com