Fresh air system with heat exchange core and air conditioner

A technology for a heat exchange core and a fresh air system, which is applied in the field of air conditioning, can solve the problems of moldy cleaning effect and dust on the heat exchange core, and achieve the effects of improving dust removal effect, improving cleanliness, and avoiding secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

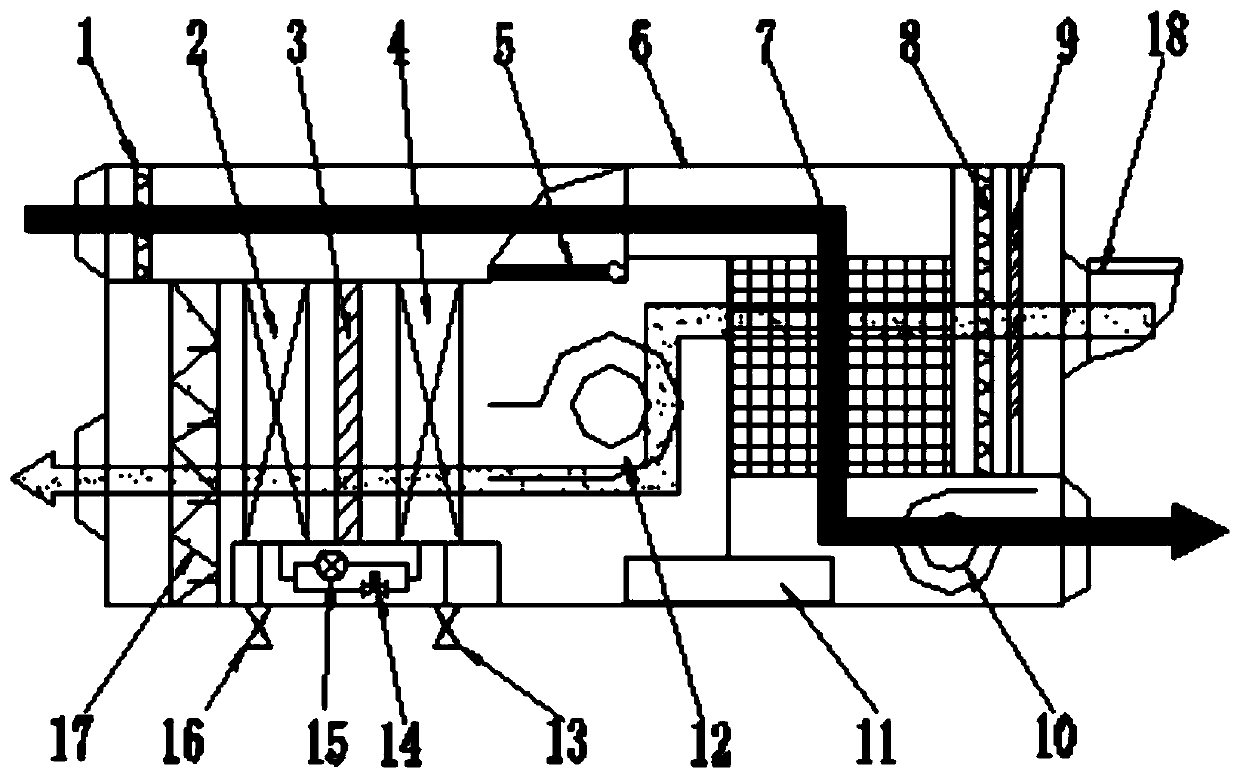

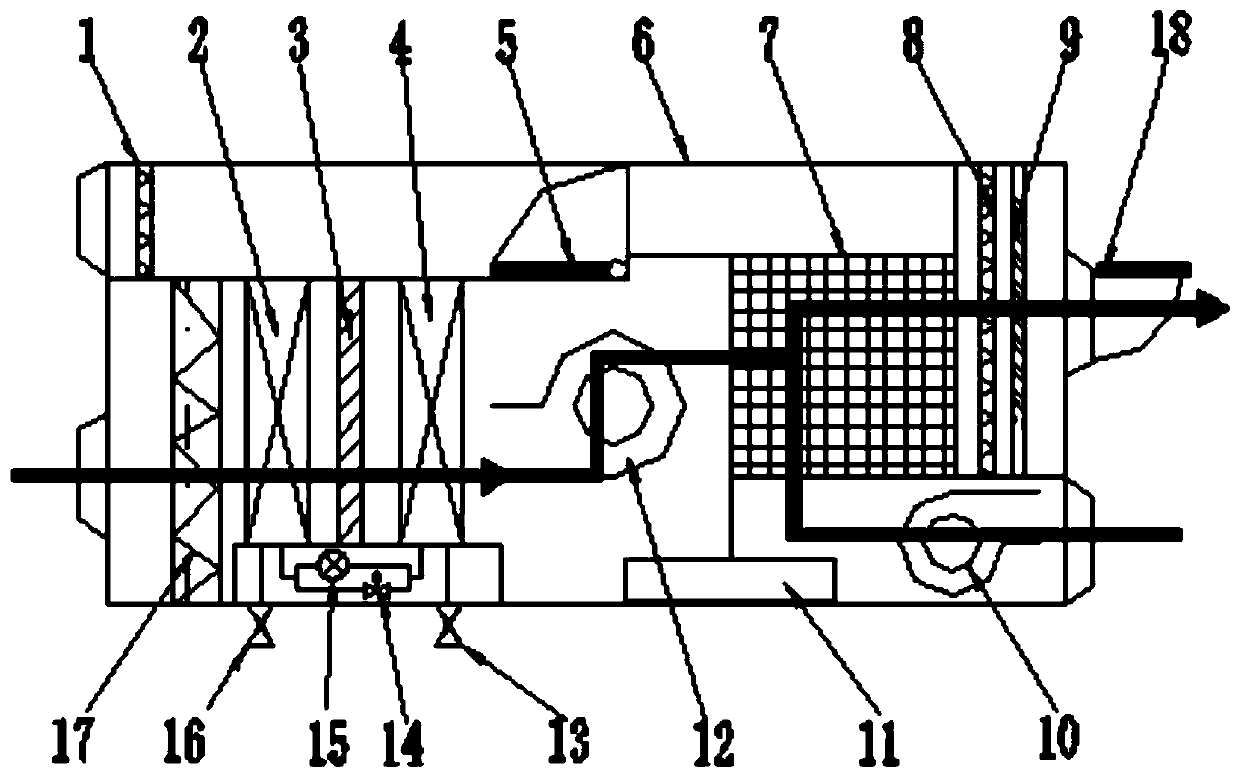

[0035] A fresh air system with a heat exchange core, such as figure 1 As shown, including the casing 6, there are two staggered fresh air ducts and return air ducts in the cabinet 6, the fresh air ducts are used for the entry of fresh air; the intersection of the fresh air duct and the return air duct is provided with Heat exchange core 7; a filter device is provided at the entrance of the fresh air duct for filtering the fresh air entering the room; the entrance of the fresh air duct is provided with a fresh air inlet valve 18, which can be opened or closed according to the usage status; A fresh air fan 12 is provided in the middle of the duct, and the heat exchange core 7 is located between the filter device and the fresh air fan 12; an electric controller 11 is provided on one side of the casing 6; a heat exchanger assembly and a humidification unit are provided on the other side of the fresh air duct. The filter assembly is used to re-filter the fresh air to ensure the qua...

Embodiment 2

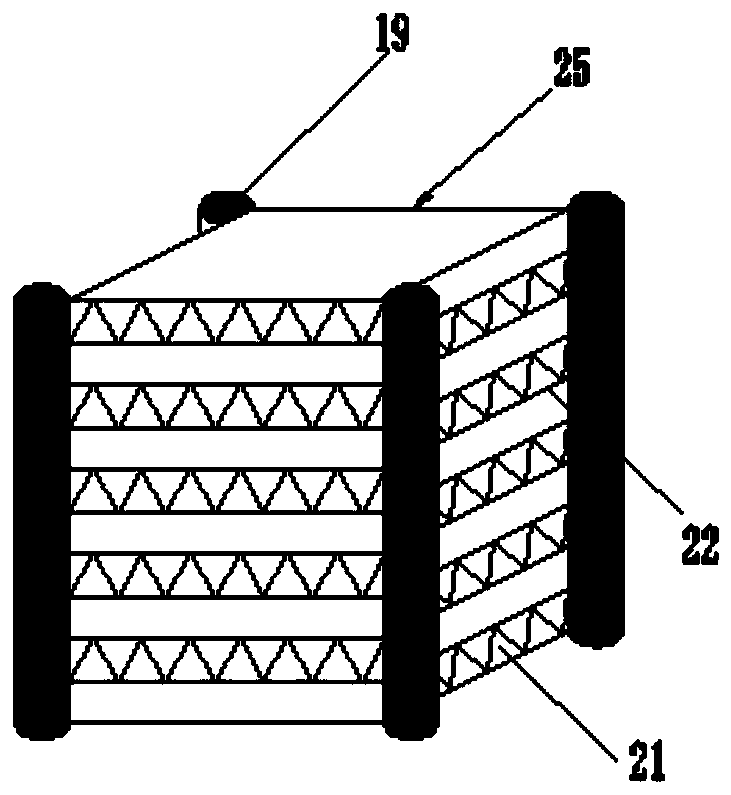

[0042] Such as image 3 As shown, the heat exchange core 7 includes a polymer film 22, a support member 21, an electric heating belt 19 and a metal frame 25, the metal frame 25 is provided with a support member 21 for supporting the polymer film 22, and the metal frame 25 An electric heating band 19 is provided on the top. The electric heating band 19 is arranged on the vertical edge of the metal frame 25. The height of the electric heating band 19 is consistent with the height of the metal frame 25. The electric heating band 19 is connected with the electric controller 11 connect.

[0043] On the basis of Embodiment 1, the filter device includes a coarse-effect filter screen 8 and a fresh-air sand-proof net 9 , and fresh air passes through the fresh-air sand-proof net 9 and the coarse-effect filter screen 8 in sequence.

[0044] The number of heat exchanger assemblies is two; the humidification filter assembly includes humidification membrane parts 3 and high-efficiency filt...

Embodiment 3

[0048] On the basis of Embodiment 2, an interface valve 13, an electromagnetic bypass valve 14, and a throttling member 15 are provided on the bottom side of the fresh air duct, and the electromagnetic bypass valve 14 is connected to the throttling member 13. There are two interface valves 13 described above, which are respectively connected to the electromagnetic bypass valve 14 and the throttling component 15 .

[0049] Fresh air blower 12 and return air blower 10 reverse, can blow off the dust attached to the surface. The wind enters from the indoor fresh air duct air outlet and the outdoor return air duct return air outlet respectively. When entering from the indoor fresh air duct air outlet, it passes through the high-efficiency filter screen 17, the throttling component 15, and the electromagnetic bypass valve respectively. 14. Interface valve 13, fresh air fan 12, heat exchange core 7, coarse-effect filter 8, fresh air sand-proof net 9, blow out the dust attached to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com