Variable-section hyperbolic C-shaped column cylindrical surface decoration construction method

A decoration construction and variable cross-section technology, which is applied in covering/lining, construction, building structure, etc., can solve the problems of insufficient smoothness of the decorative surface, single force-bearing form, and rigid decorative surface, so as to improve the cutting speed and accuracy , The effect of reducing personnel investment and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

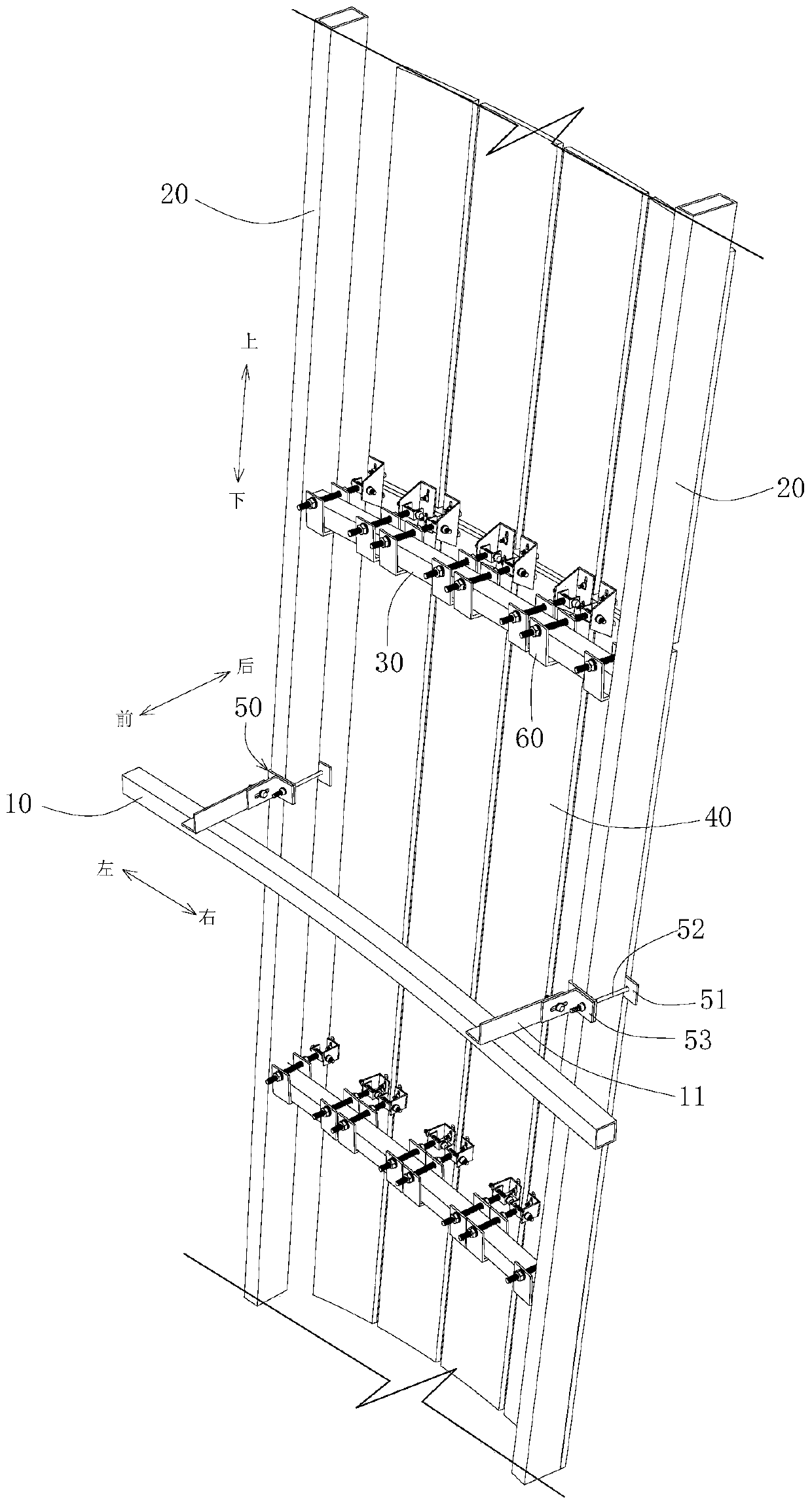

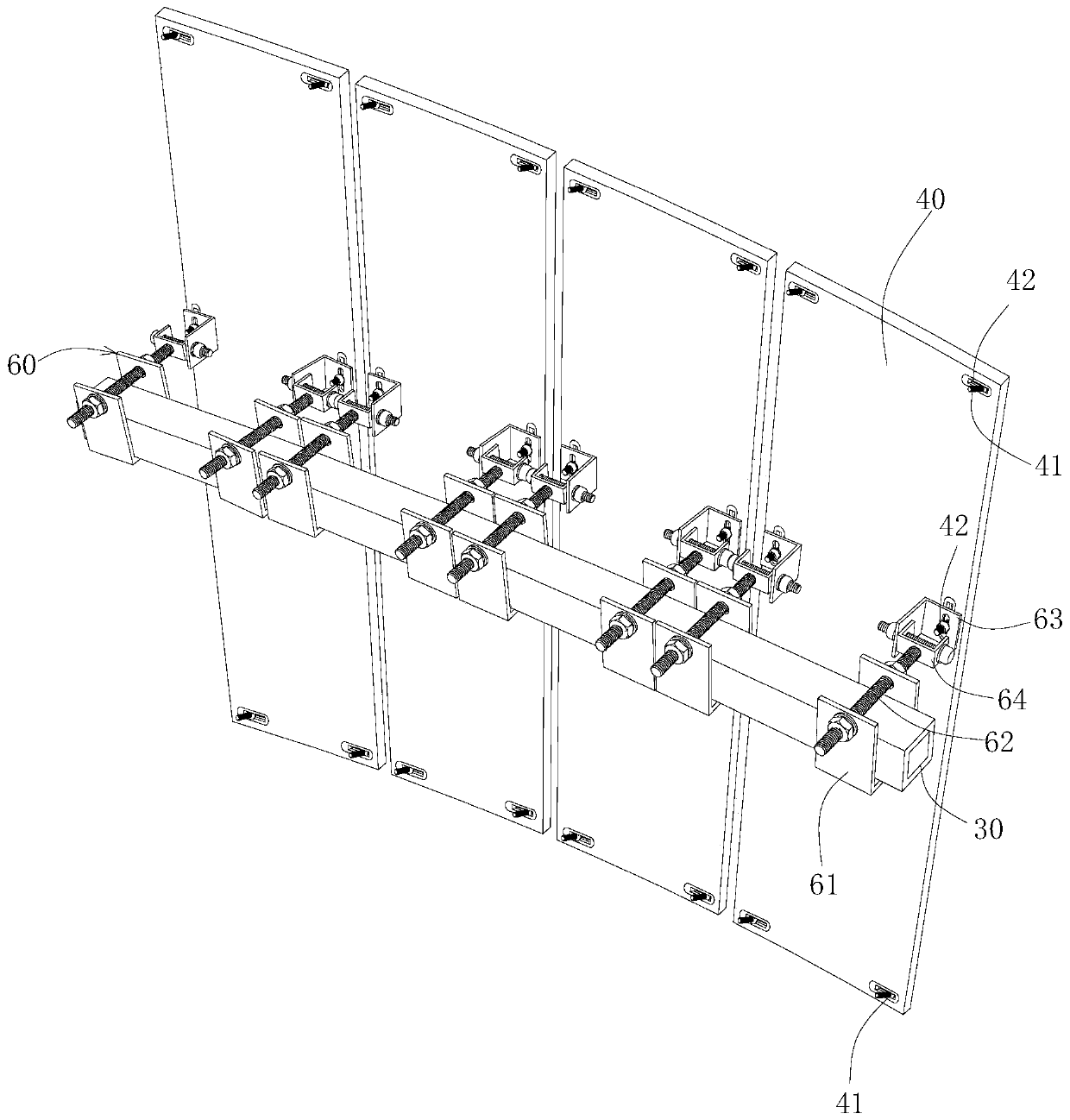

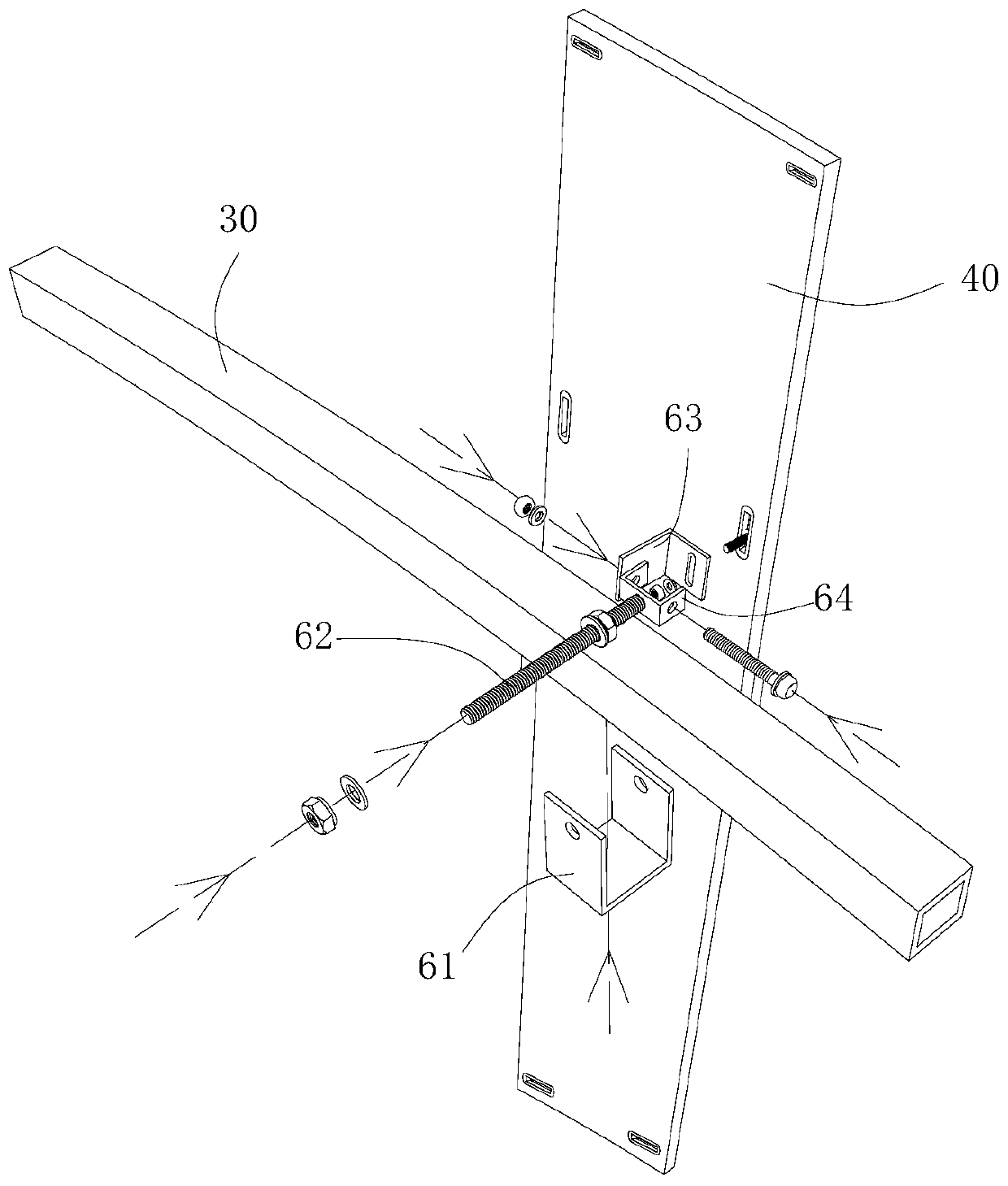

[0032] The following is attached with the manual Figure 1-4 The present invention is described in detail with specific examples.

[0033] The invention relates to a construction method for cylindrical surface decoration of hyperbolic C-shaped columns with variable cross-section, comprising the following steps:

[0034] Step one, construction preparation

[0035] 1.1 Mechanical preparation

[0036] Equipment required for construction: aerial work vehicle, electric welding machine, desktop drilling machine, cutting machine, total station, hand drill, torque wrench, open-end wrench, 5M steel tape measure, laser rangefinder, hammer, 3D laser scanner (Model TrimbLeTX8), matching point cloud data processing software, BIM modeling software, BIM workstation hardware matching, etc.

[0037] 1.2 Material preparation

[0038] Prepare the materials required for construction: additional horizontal keel, vertical keel, horizontal keel, additional vertical keel, U-shaped connector 1, U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com