Explosive segmental detonation cracking method at the root of the surface annular groove during pipe blanking

An annular groove and pipe technology, which is applied in the field of segmental detonation and initiation of explosives at the root of the annular groove on the surface of the pipe during cutting, can solve the problems of long cutting time, low processing efficiency, collapse of the pipe wall, etc., and save the amount of medicine. , The effect of shortening the blanking cycle and improving the blanking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] The method for detonating and cracking the root of the annular groove on the surface of the explosive by segmental detonation during the blanking of the pipe comprises the following steps:

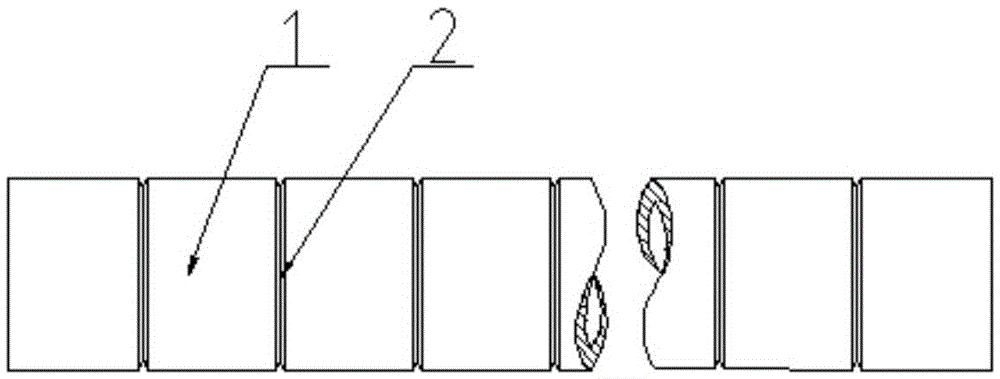

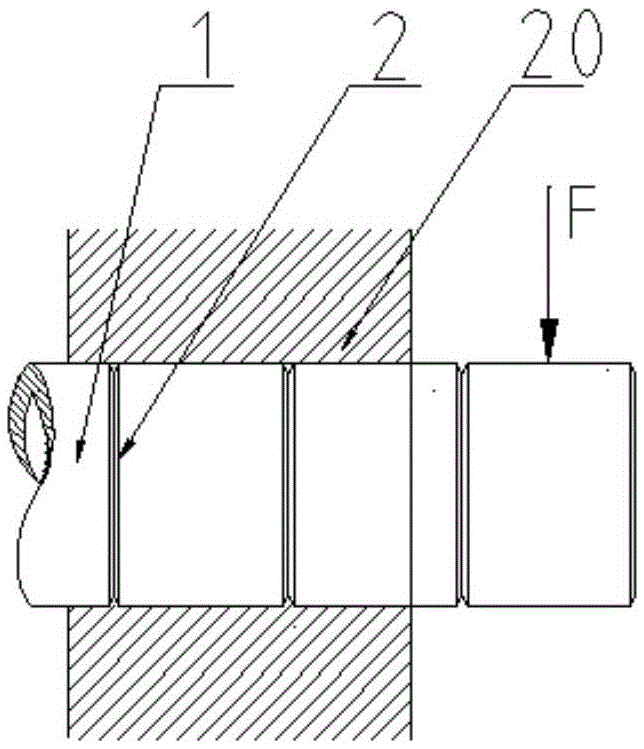

[0024] Step 1. Before cracking, the outer surface of the long pipe 1 is cut into an annular V-groove 2 according to the cutting length of each section, such as figure 1 shown;

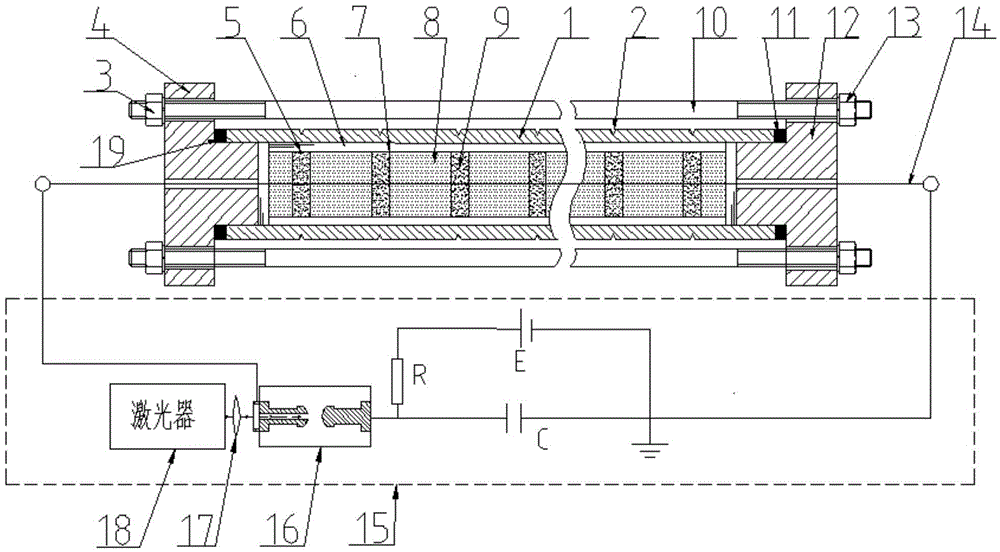

[0025] Step 2. When assembling, fill the long pipe 1 with a long detonation tube 5 of equal diameter, make the powder column 9 correspond to the root section of the annular V groove 2, and seal the first flange head 4 and the second flange The head 12 is installed and clamped at both ends of the long pipe 1, and the first flange head 4 and the second flange head 12 are tensioned axially with the first bolt 10;

[0026] Step 3. When cracking, turn on the laser 18, trigger the ball gap high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com