Polyester high-strength netting twine with self-luminous function and preparation method thereof

A self-illuminating and functional technology, applied in the manufacture of rayon, complete sets of equipment for the production of rayon, stretching spinning, etc., can solve the problem of difficulty in guaranteeing the strength of self-luminous polyester high-strength yarn, poor dispersion of luminescent powder, and poor light storage effect of fibers and other problems to achieve the effect of avoiding low fracture strength, avoiding poor mechanical properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

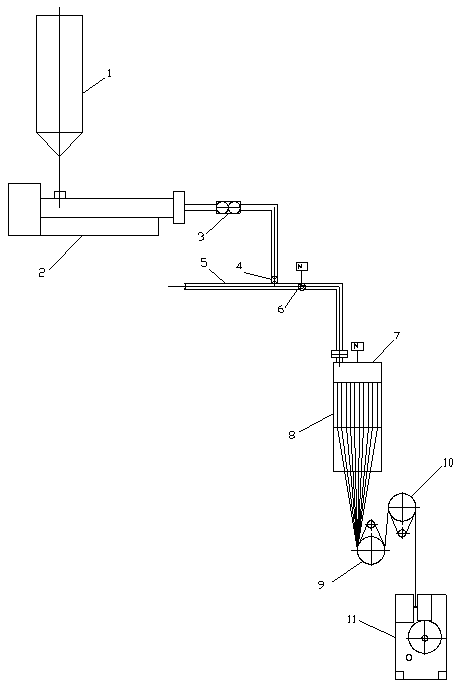

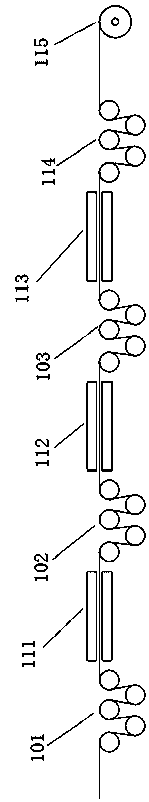

[0031] like Figure 1-2 The present invention provides a kind of preparation method of polyester high-strength fishing net thread with self-illuminating function, comprising the following steps:

[0032] 1) The alkaline earth aluminate luminescent material and the alkaline earth silicate luminescent material are mixed and compounded according to the mass ratio of 1:0.5~0.8, and the mixed luminescent powder is obtained through grinding and sieving;

[0033] 2) After uniformly mixing ordinary polyester chips with the mixed luminescent powder, the self-luminescent polyester masterbatch is obtained through twin-screw melt extrusion and granulation, and the self-luminescent polyester masterbatch is pre-crystallized and dried to Moisture content <25ppm; the mass ratio of the mixed luminescent powder to the common polyester chips is 1~3:7~9;

[0034] 3) Put the self-luminous polyester masterbatch obtained through step 2) into a screw extruder for melt extrusion to obtain a self-lumi...

Embodiment 1

[0043] 1. Preparation of self-luminous polyester masterbatch:

[0044] 10 parts by weight of alkaline earth aluminate luminescent material SrAl 2 o 4 :Eu 2+ , Dy 3+ and 6 parts by weight of alkaline earth silicate luminescent material Sr 3 MgSi 2 o 8 :Eu 2+ , Dy 3+ Mix and compound, pass through a 325-mesh sieve after being ground by a ball mill to obtain a mixed luminescent powder with a particle size of 40 μm, take 12 parts by weight of the mixed luminescent powder and 48 parts by weight of polyester chips with an intrinsic viscosity of 0.66dl / g and mix evenly , obtained from luminous polyester masterbatch by twin-screw melt extrusion and granulation.

[0045] 2. Spinning self-luminous polyester FDY filament:

[0046] according to figure 1 Melt direct spinning polyester FDY production flow chart with screw on-line adding device for spinning self-luminous polyester FDY filaments, specifically:

[0047] (1) Put the self-luminous polyester masterbatch into the chip d...

Embodiment 2

[0054] 1. Preparation of self-luminous polyester masterbatch:

[0055] 10 parts by weight of alkaline earth aluminate luminescent material SrAl 2 o 4 :Eu 2+ , Dy 3+ and 5 parts by weight of alkaline earth silicate luminescent material Sr 3 MgSi 2 o 8 :Eu 2+ , Dy 3+ Mix and compound, pass through a 1340-mesh sieve after being ground by a ball mill to obtain a mixed luminescent powder with a particle size of 10 μm, take 6 parts by weight of the mixed luminescent powder and 54 parts by weight of polyester chips with an intrinsic viscosity of 0.64dl / g and mix evenly , obtained from luminous polyester masterbatch by twin-screw melt extrusion and granulation.

[0056] 2. Spinning self-luminous polyester FDY filament:

[0057] according to figure 1 Melt direct spinning polyester FDY production flow chart with screw on-line adding device for spinning self-luminous polyester FDY filaments, specifically:

[0058](1) Put the self-luminous polyester masterbatch into the chip dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com