High-thermal-conductivity and high-wear-resistance silicon nitride ceramic as well as preparation method and application thereof

A technology of silicon nitride ceramics with high thermal conductivity, applied in the field of ceramics, can solve the problems of difficult tool processing, prolong tool life, and low diamond toughness, and achieve the effects of enhancing bonding strength, inhibiting graphitization, and good cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Ti-coated diamond (10% mass fraction), particle size 64μm, Ti film thickness 150nm; Si 3 N 4 (80% mass fraction), particle size 0.5 μm, purity 99.99wt.%; MgO (5% mass fraction), particle size 100nm, purity 99.99wt.%; Yb 2 o 3 (5% mass fraction), particle size 3 μm, purity 99.99%. Put the powder into a nylon ball mill jar, add ethanol and Si with a diameter of 5-10mm 3 N 4 The ball is used as the ball milling medium, the ball milling time is 24 hours, the rotation speed is 120r / min, and the mixed powder is obtained after ball milling and drying.

[0029] 2. Put the mixed powder in N 2 Under the atmosphere, add 35MPa axial pressure, heat up to 1600°C at a rate of 100°C / min, hold for 10min, and go through discharge plasma sintering. The discharge plasma current is DC pulse current. 5ms, the density of Si containing Ti-coated diamond particles is 97%. 3 N 4 base ceramics.

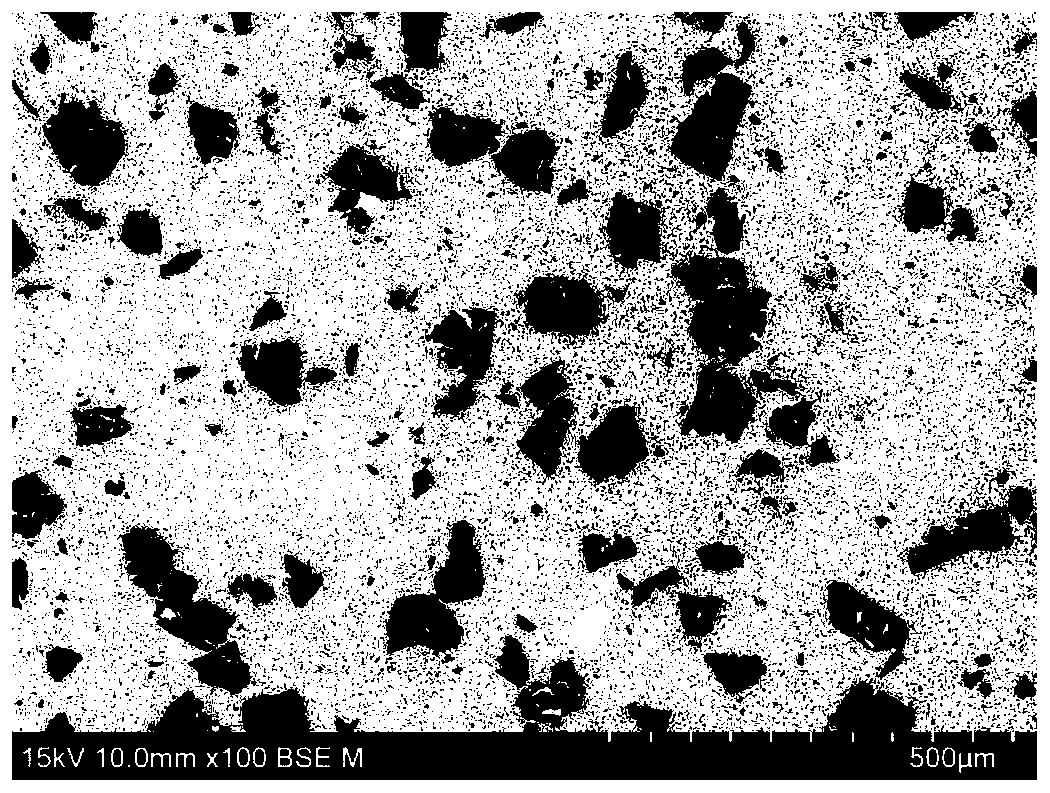

[0030] figure 1 Be the Si of the diamond that contains 10wt.% Ti plating in embodiment 1...

Embodiment 2

[0032] 1. Ti-coated diamond (20% mass fraction), particle size 64μm, Ti film thickness 150nm; Si 3 N 4 (70% mass fraction), particle size 0.5 μm, purity 99.99wt.%; MgO (5% mass fraction), particle size 100nm, purity 99.99wt.%; Yb 2 o 3 (5% mass fraction), particle size 3 μm, purity 99.99%. Put the powder into a nylon ball mill jar, add ethanol and Si with a diameter of 5-10mm 3 N 4 The ball is used as the ball milling medium, the ball milling time is 24 hours, the rotation speed is 120r / min, and the mixed powder is obtained after ball milling and drying.

[0033] 2. Put the mixed powder in N 2Under the atmosphere, apply an axial pressure of 35MPa, heat to 1600°C at a rate of 100°C / min, and hold for 10 minutes. After discharge plasma sintering, the discharge plasma current is a DC pulse current. 5ms, the Si containing Ti-coated diamond particles with a density of 96% was produced 3 N 4 base ceramics.

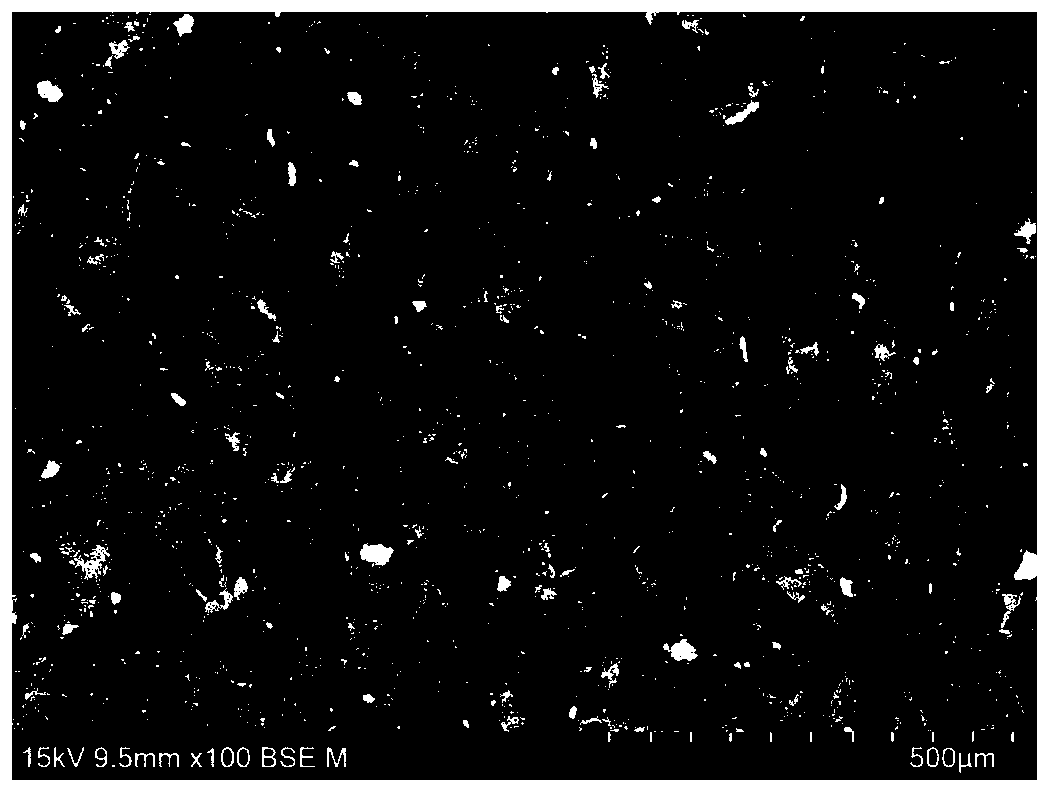

[0034] figure 2 Be the Si of the diamond that contains 20wt.% Ti ...

Embodiment 3

[0036] 1. Ti-coated diamond (30% mass fraction), particle size 64μm, Ti film thickness 150nm; Si 3 N 4 (60% mass fraction), particle size 0.5 μm, purity 99.99wt.%; MgO (5% mass fraction), particle size 100nm, purity 99.99wt.%; Yb 2 o 3 (5% mass fraction), particle size 3 μm, purity 99.99%. Put the powder into a nylon ball mill jar, add ethanol and Si with a diameter of 5-10mm 3 N 4 The ball is used as the ball milling medium, the ball milling time is 24 hours, the rotation speed is 120r / min, and the mixed powder is obtained after ball milling and drying.

[0037] 2. Put the mixed powder in N 2 Under the atmosphere, apply an axial pressure of 35MPa, heat to 1600°C at a rate of 100°C / min, hold for 10min, and undergo discharge plasma sintering. 5ms, the Si containing Ti-coated diamond particles with a density of 96% was produced 3 N 4 base ceramics.

[0038] image 3 Be the Si of the diamond that contains 30wt.% Ti plating in embodiment 3 3 N 4 SEM micrographs of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com