Sealing method for titanium-glass seal assembly

A technology of glass sealing and components, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve poor insulation resistance, poor performance stability of sealed products, poor wettability between titanium and titanium alloys and glass, etc. problems, to eliminate the formation of nitrides and oxides, improve production efficiency and yield, and avoid the effect of titanium alloy crystal phase transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

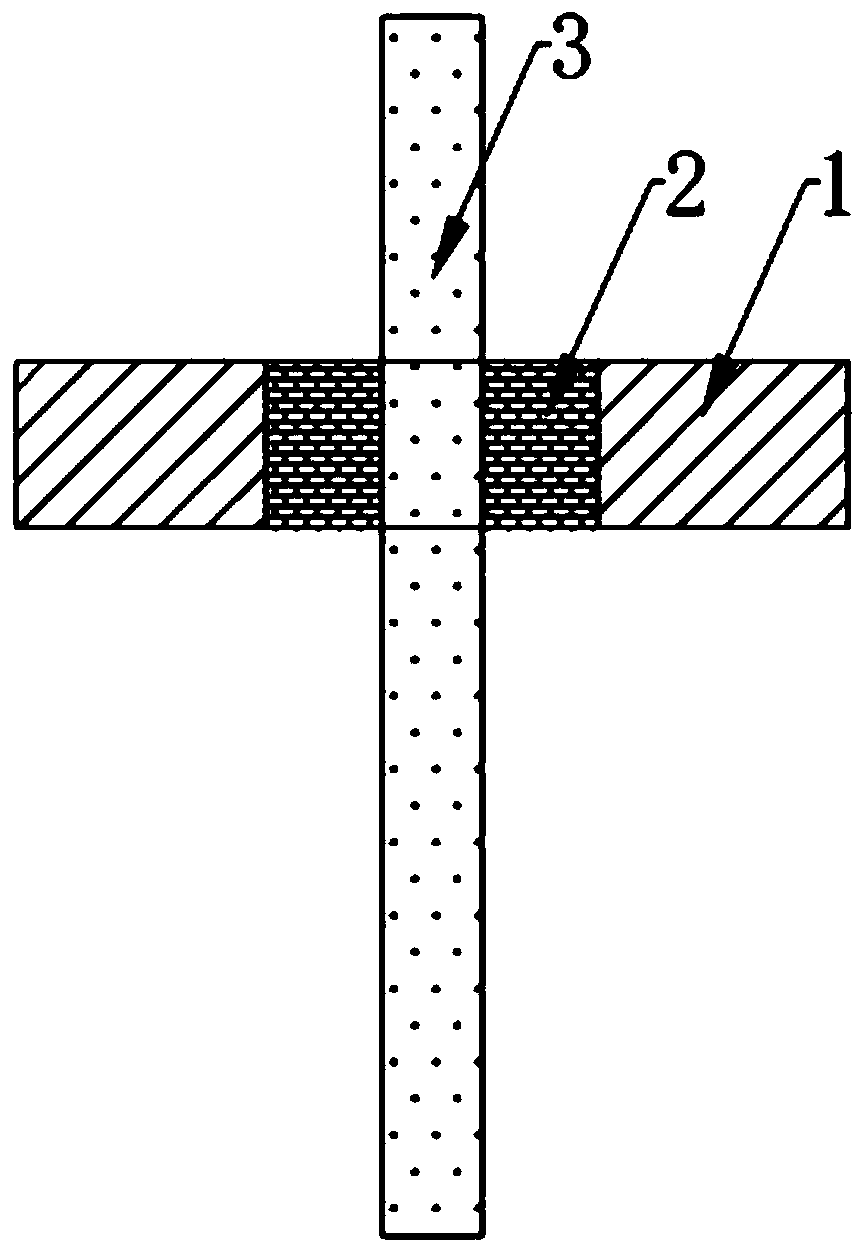

Image

Examples

Embodiment 1

[0042]Pre-oxidize the metal shell at 300°C for 30 minutes, pre-oxidize the metal conductor stem at 300°C for 30 minutes, then put the metal shell, the glass body in the through hole of the metal shell, and the metal conductor stem into the sintering mold in the corresponding order In the process, put the semi-finished components together with the sintering mold into the high-temperature sintering furnace, introduce a mixture of 75% nitrogen and 25% hydrogen as a protective gas, raise the temperature to 750°C at 5°C / min, and keep it for 40 minutes for sintering to soften or melt A good tight seal is formed between the lower glass body, the metal conductor stem and the metal shell, and annealed at 5°C / min to 500°C for 15 minutes, and then lowered to room temperature at 10°C / min to obtain titanium-glass As for the sealing assembly, the formed titanium-glass sealing assembly is tested, and its performance parameters all meet the requirements for use.

Embodiment 2

[0044] Pre-oxidize the metal shell at 400°C for 20 minutes, pre-oxidize the metal conductor stem at 400°C for 20 minutes, then put the metal shell, the glass body in the through hole of the metal shell, and the metal conductor stem into the sintering mold in the corresponding order In the process, put the semi-finished components together with the sintering mold into the high-temperature sintering furnace, introduce a mixed gas of 90% nitrogen and 10% hydrogen as a protective gas, raise the temperature to 800°C at 15°C / min, and keep it for 25 minutes for sintering to soften or melt A good tight seal is formed between the glass body under the metal conductor core and the metal shell, and annealed at 15°C / min to 550°C for 10 minutes, and then cooled to room temperature at 15°C / min to obtain titanium- Glass sealed components.

Embodiment 3

[0046] Pre-oxidize the metal shell at 500°C for 10 minutes, pre-oxidize the metal conductor stem at 500°C for 10 minutes, then put the metal shell, the glass body set in the through hole of the metal shell, and the metal conductor stem into the sintering mold in the corresponding order In the process, put the semi-finished components together with the sintering mold into the high-temperature sintering furnace, introduce a mixed gas of 95% nitrogen and 5% hydrogen as the protective gas, raise the temperature to 880°C at 20°C / min, keep it for 15 minutes for sintering, and soften or melt the A good tight seal is formed between the glass body under the metal conductor core and the metal shell. It is annealed at 25°C / min to 550°C for 10 minutes, and then cooled to room temperature at 20°C / min to obtain excellent performance. Titanium-glass sealing components for aerospace connectors.

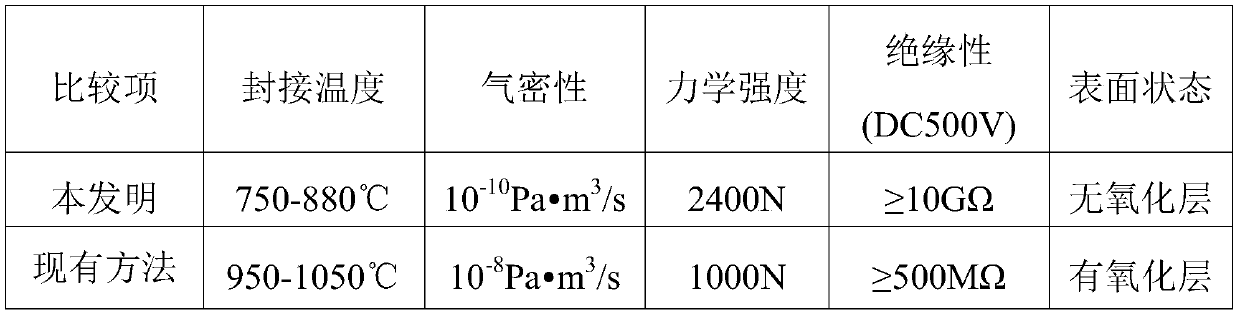

[0047] The titanium-glass sealing assembly prepared by the invention has excellent performance, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com