Immersed ultrafiltration process for automobile factory common sewage treatment

A technology of sewage treatment and ultrafiltration process, applied in water/sewage treatment, biological water/sewage treatment, flotation water/sewage treatment, etc. The effect of large quantities, increasing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

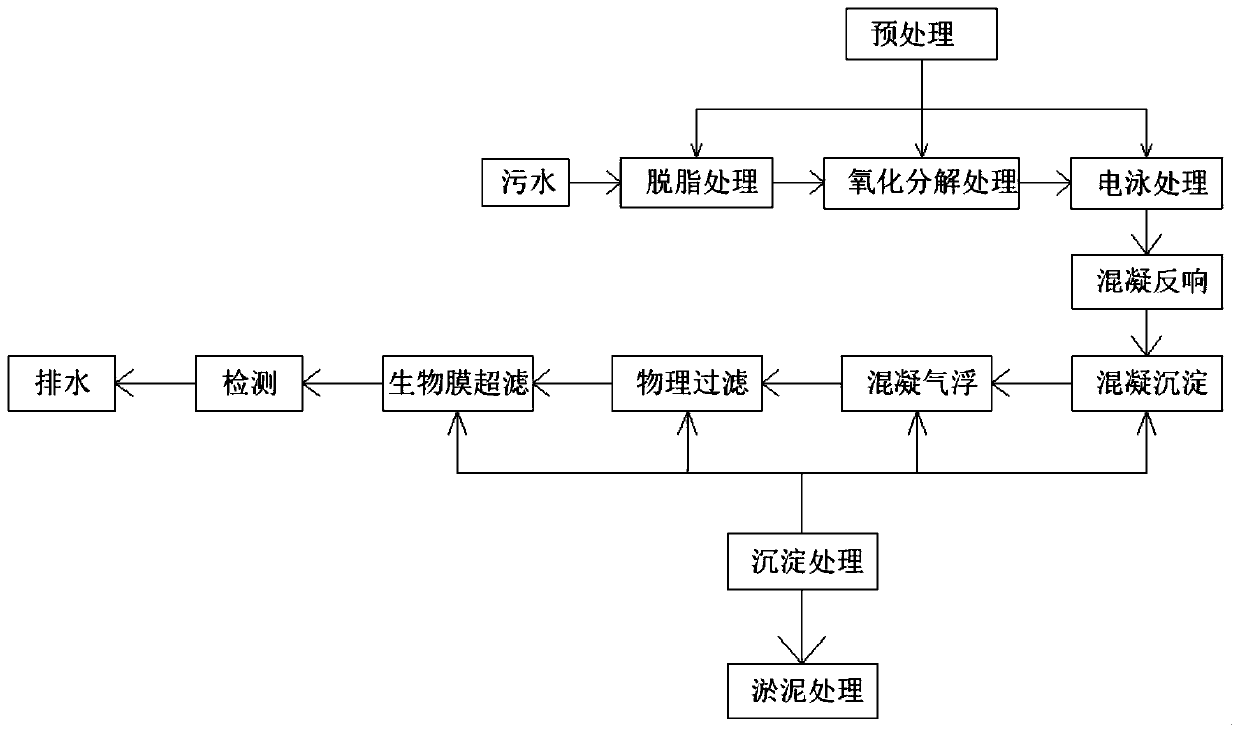

[0038] The invention provides a technical solution: an immersion ultrafiltration process for sewage treatment commonly used in automobile factories. The sewage treatment process includes degreasing treatment, oxidation decomposition treatment, electrophoresis treatment, coagulation reaction, coagulation precipitation, coagulation Flotation, physical filtration, biofilm ultrafiltration, detection, sludge treatment, the specific operations are as follows:

[0039] Step 1: Degreasing

[0040] The waste liquid is subjected to demulsification pretreatment by acidification method, adding inorganic acid to the waste liquid to adjust the pH to 2-3, and the higher fatty acid soap in the emulsifier precipitates fatty acids. These higher fatty acids are insoluble in water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com