Flotation method for zinc oxide in sulphide ore tailings

A technology of sulfide ore and zinc oxide, which is applied in flotation, solid separation, etc., can solve the problems of expensive integration agent, large consumption of chemicals, and less industrial application, so as to reduce the cost of chemicals, improve the grade and recovery rate, and improve sorting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

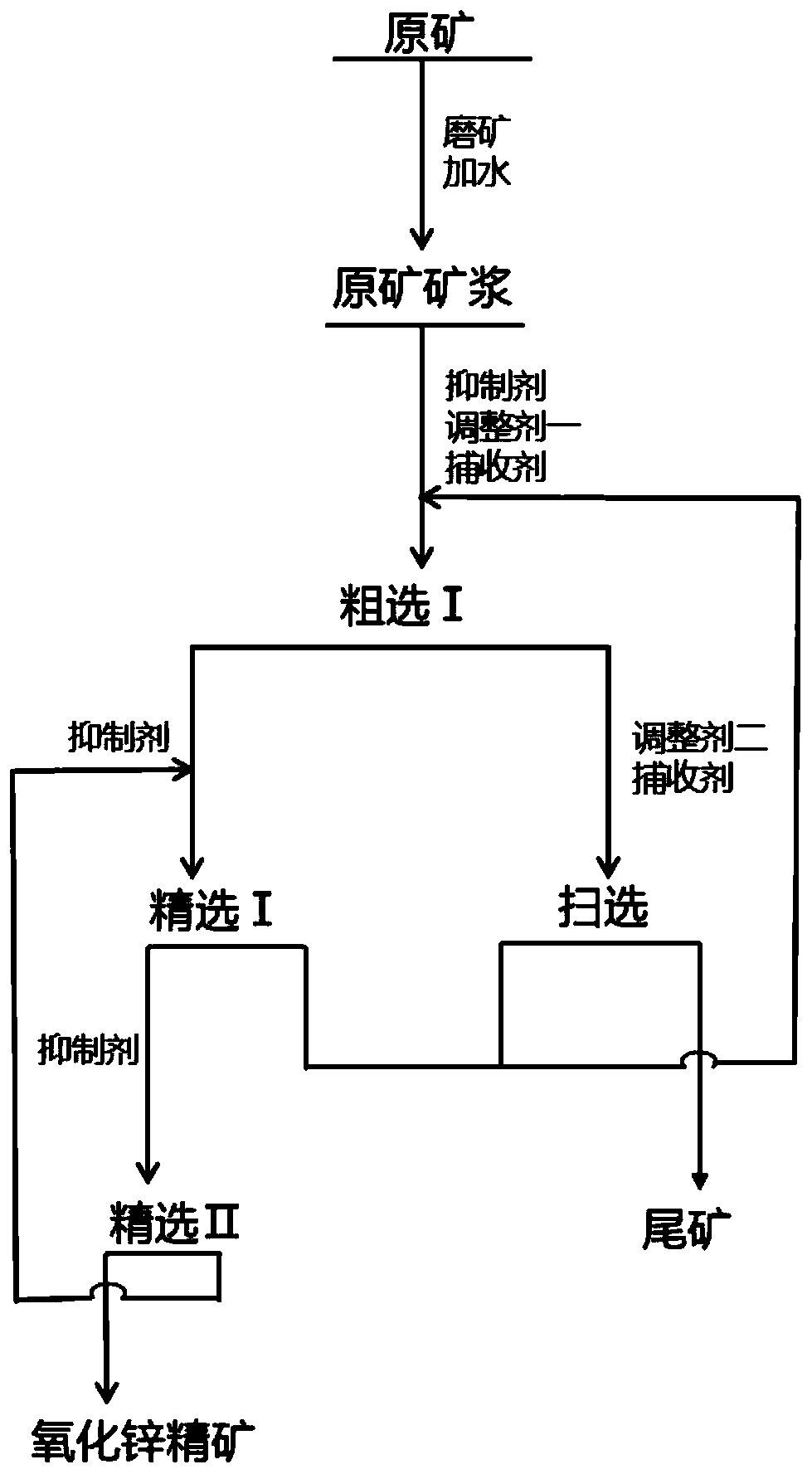

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment provides a kind of flotation method of zinc oxide in sulfide ore tailings, comprising the following steps:

[0030] S1. Take the sulfide ore tailings for crushing and then enter the ball mill for grinding. The ground material enters the spiral classification and screens out the pulp fineness less than 0.074mm, accounting for 80%. The unqualified ones are returned to the ball mill to continue grinding;

[0031] S2. Prepare a mixed solution, mix the inhibitor, regulator 1 and collector together in a certain proportion, add water and stir until completely dissolved;

[0032] The inhibitor is that sodium silicate and sodium hexametaphosphate are mixed according to the dosage ratio of 1:4, and the consumption of the sodium hexametaphosphate is 500g / t;

[0033] Described adjusting agent one is that sodium sulfide and sodium carbonate are mixed according to 1:0.4; The consumption of described sodium sulfide is 2500g / t;

[0034] Described collector is th...

Embodiment 2-5

[0039] Embodiment 2-5 provides a kind of flotation method of zinc oxide in sulfide ore tailings, compared with embodiment 1, the difference is that in step S1, the ratio of qualified pulp fineness after screening is less than 0.074mm is changed , except for the above differences, other operations are the same and will not be repeated here; the specific condition parameters and the grade and recovery rate of the zinc oxide concentrate separated by flotation are shown in the table below.

[0040] Example Proportion of pulp fineness less than 0.074mm (%) grade% Recovery rate% 1 80 46.1 92.1 2 70 44.8 88.5 3 85 46.7 92.4 4 65 40.3 85.6 5 90 47.2 92.7

[0041] It can be seen from the results in the above table that when the pulp fineness is less than 0.074mm, it accounts for 70-85%, and the recovery rate of zinc oxide in pyrite tailings basically reaches a balance. High, the recovery rate of pyrite increases with the increase o...

Embodiment 6-9

[0043] Embodiment 6-9 provides a kind of flotation method of zinc oxide in sulfide ore tailings, compared with embodiment 1, the difference is that in step S2, sodium silicate and sodium hexametaphosphate in the inhibitor are changed In addition to the above differences, other operations are the same, and will not be repeated here; the specific condition parameters and the grade and recovery of the zinc oxide concentrate separated by flotation are shown in the table below.

[0044] Example Dosage ratio grade% Recovery rate% 6 1:0 41.5 85.3 7 1:2.5 43.6 90.9 8 1:5 46.1 92.1 9 0:1 40.3 86.2

[0045] It can be seen from the results in the above table that with the increase of the dosage ratio of sodium silicate and sodium hexametaphosphate in the inhibitor, the recovery of zinc in zinc oxide concentrate first increases and then decreases. When the dosage of sodium silicate is 125g When the consumption of / t, sodium hexametaphosphate...

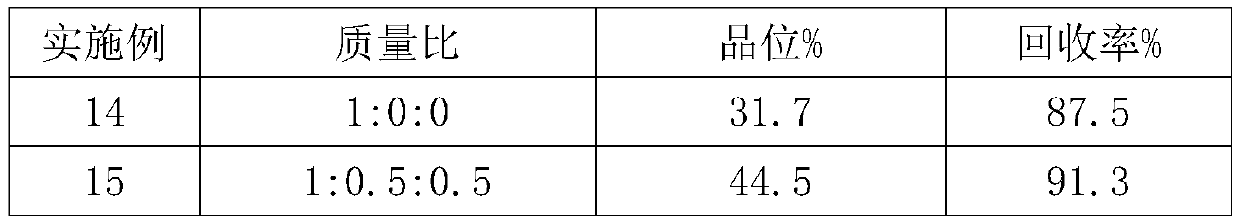

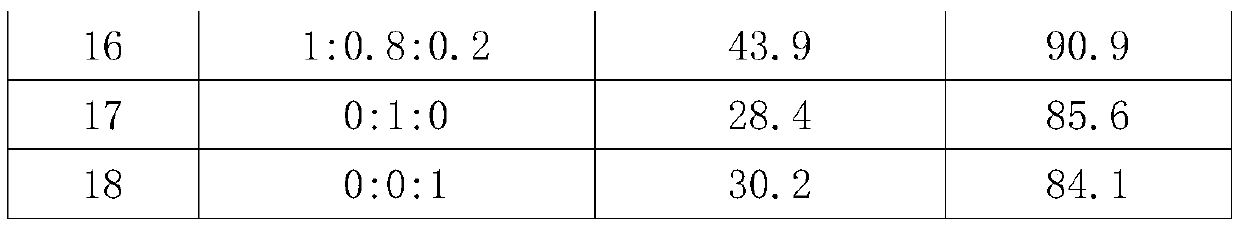

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com