Tungsten trioxide-molybdenum disulfide type composite photocatalyst, preparation method and applications thereof

A molybdenum disulfide and tungsten trioxide technology, applied in the field of photocatalytic materials, can solve the problems of poor stability, high photo-generated carrier recombination rate, poor light response, etc., and achieve mild operating conditions, environmental friendliness, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides the WO described in the technical solution 3 -MoS 2 The preparation method of type composite photocatalyst comprises the following steps:

[0029] flake MoS 2 Dispersed in alcoholic solvents to obtain MoS 2 Dispersions;

[0030] Dissolving tungsten salt in a solvent to obtain a tungsten salt solution;

[0031] The MoS 2 The dispersion liquid is mixed with the tungsten salt solution to undergo an oxidation reaction to obtain a tungsten trioxide-molybdenum disulfide composite photocatalyst.

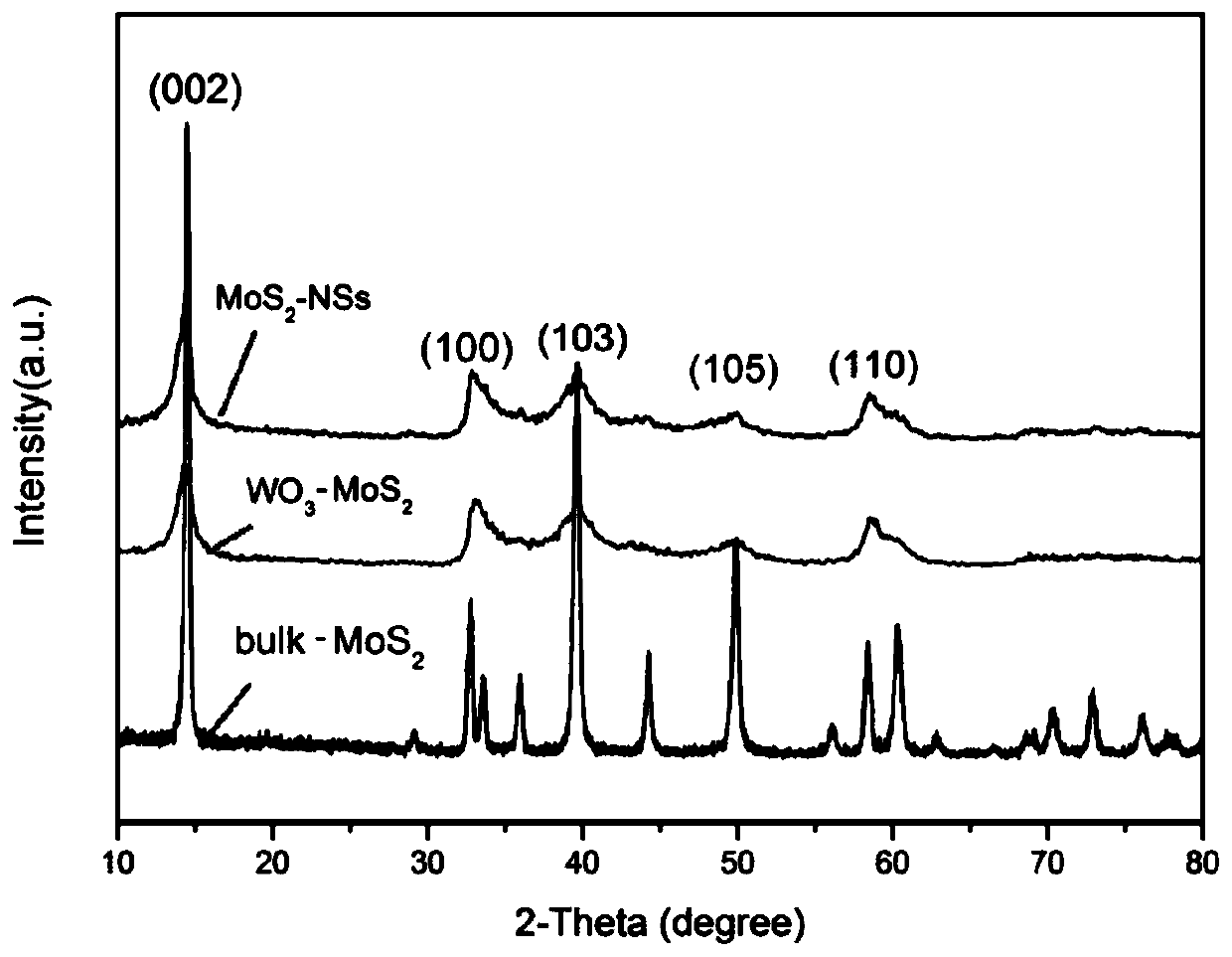

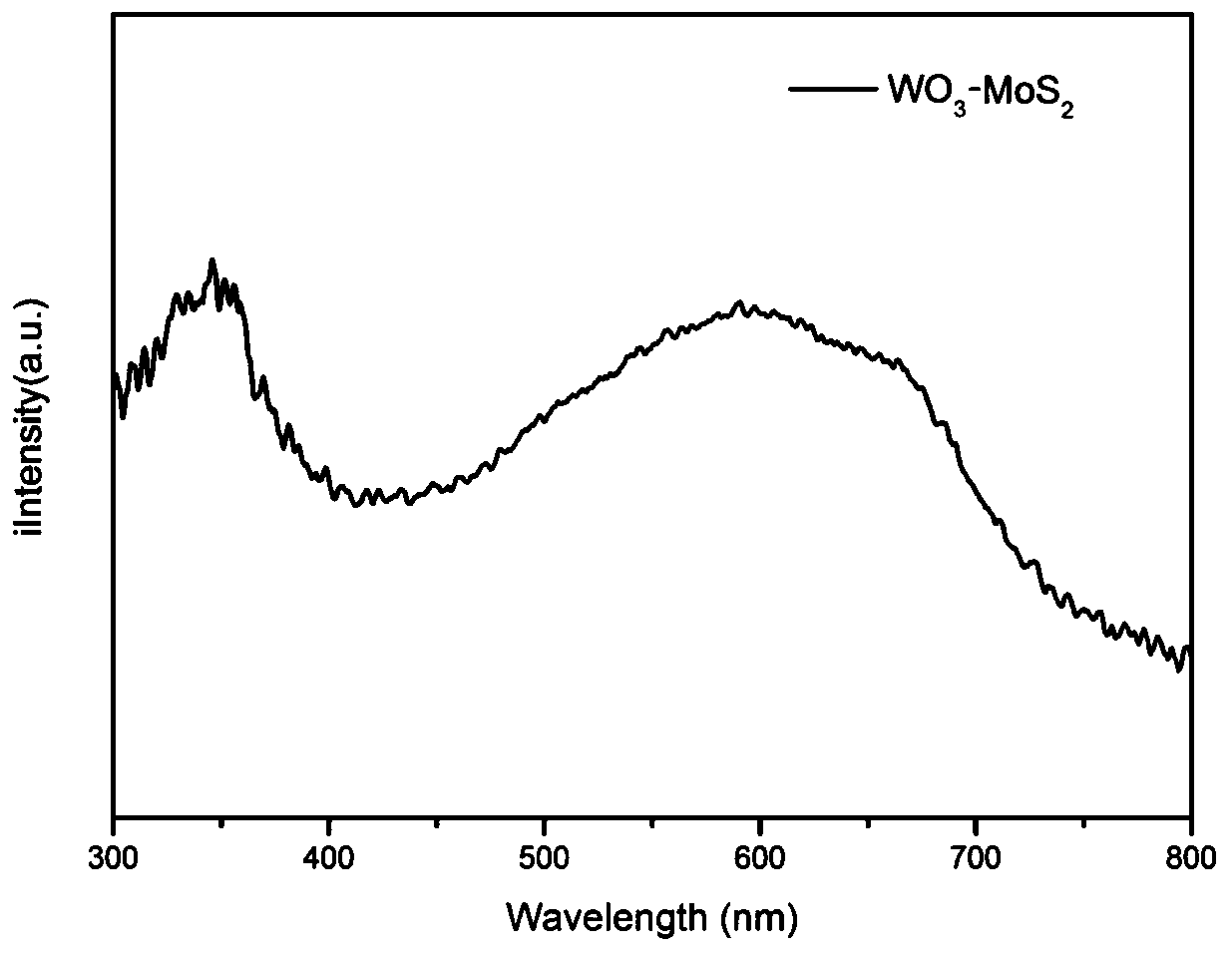

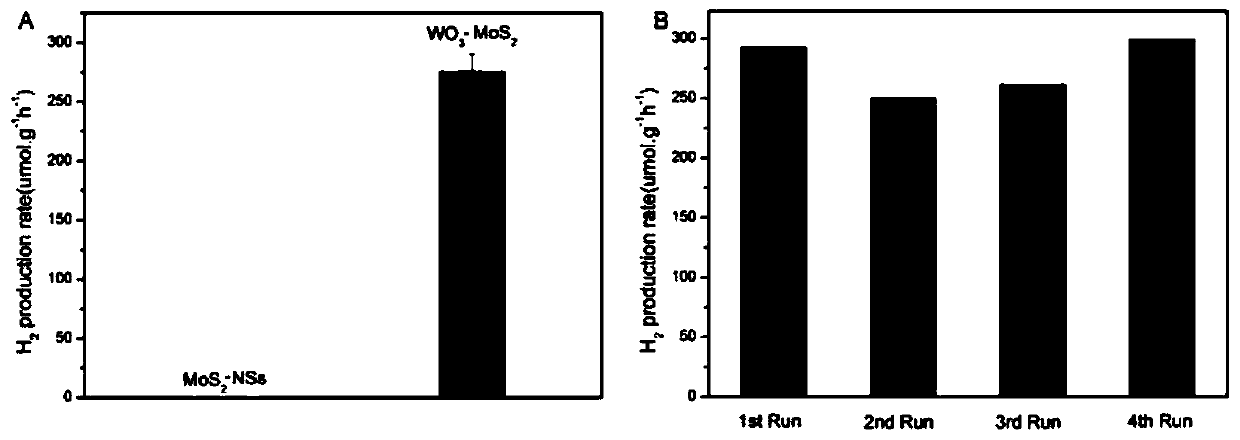

[0032] The preparation method provided by the invention has the characteristics of simple process, low cost, no pollution, etc., and can prepare WO with controllable component content, high utilization rate of visible light, efficient and stable photocatalytic decomposition of water to produce hydrogen 3 -MoS 2 composite photocatalyst.

[0033] In the present invention, flake MoS 2 Dispersed in alcoholic solvents to obtain MoS 2 Dispersio...

Embodiment 1

[0049] (1) Take 2g bulk MoS 2 Place in a sealed flat-bottomed flask protected by argon, slowly add 20 mL of n-butyllithium hexane solution with a concentration of 1.6 mol / L with a syringe, stir for 48 hours, centrifuge, and wash with hexane to obtain Li 2.2 MoS 2 ; the Li 2.2 MoS 2 Ultrasonic dispersion in water, sonication at 260W ultrasonic power for 12h, first centrifuged at 2000r / min, the lower layer did not peel off the solid, then centrifuged at 10000r / min to remove the lower solid, washed with water until neutral, freeze-dried to obtain Flake MoS with a thickness of 1-3nm 2 ;

[0050] (2) Take 0.15g of flake MoS obtained in step (1) 2 Ultrasonic dispersion into 50mL of ethylene glycol, another 32.60mg of tungsten chloride was dissolved in 20mL of ethylene glycol and fully stirred, the above MoS 2 The dispersion liquid was mixed with tungsten chloride ethylene glycol solution, stirred well and then transferred into an eggplant-shaped bottle. With the assistance of ...

Embodiment 2

[0053] (1) Take 2g bulk MoS 2 Place in a sealed flat-bottomed flask protected by argon, slowly add 20 mL of n-butyllithium hexane solution with a concentration of 1.6 mol / L with a syringe, stir for 48 hours, centrifuge, and wash with hexane to obtain Li 2.2 MoS 2 ; the Li 2.2 MoS 2 Ultrasonic dispersion in water, ultrasonic 12h at 260W ultrasonic power, first centrifuged at 2000r / min to remove the upper solid, then centrifuged at 10000r / min to remove the lower solid, washed with water until neutral, freeze-dried to obtain the thickness Flake MoS with a thickness of 1-3nm 2 ;

[0054] (2) Take 0.4g of flake MoS obtained in step (1) 2 Ultrasonic dispersion into 50mL of ethylene glycol, another 10.8mg of ammonium metatungstate dissolved in 20mL of water and fully stirred, the above MoS 2 The dispersion liquid was mixed with the ammonium metatungstate aqueous solution, stirred well and then transferred into an eggplant-shaped bottle. With the assistance of 300W microwave, it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com