Positioning and guiding device for on-site cutting detection of adhesive force of metal structure coating

A metal structure, positioning-oriented technology, applied in the field of machinery, can solve the problems of increasing the detection time, evaluation, easy to scratch, etc., and achieve the effect of shortening the detection time, convenient switching, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

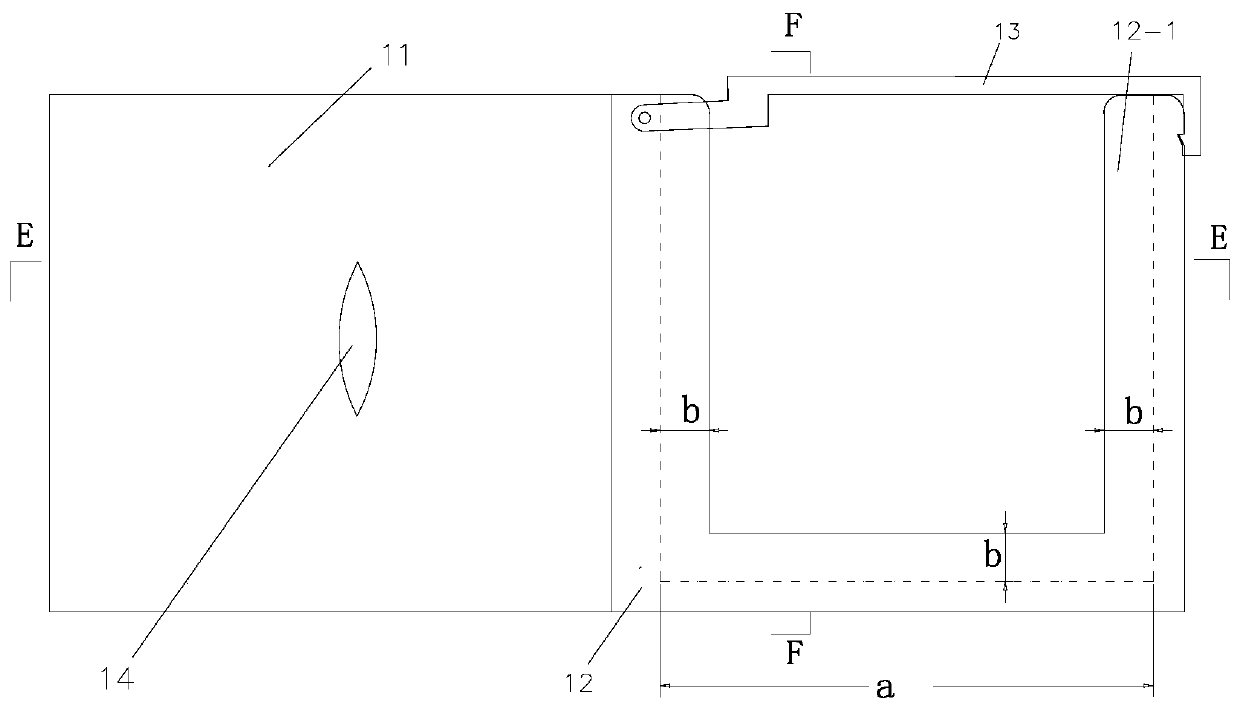

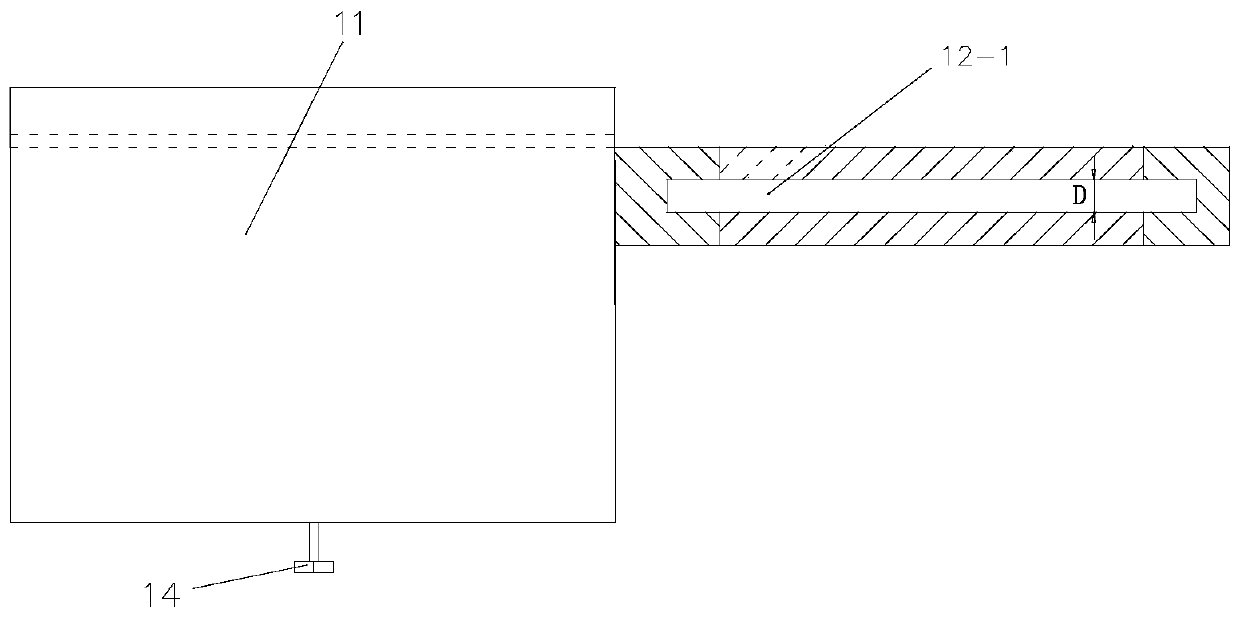

[0032] The embodiment shown in the accompanying drawings is a positioning guide device for on-site cutting detection of metal structure coating adhesion, including a magnetic base 11 (conventional component) and a guide card. Two retaining strips 15 ( image 3 The middle display is a trapezoidal bar), suitable for installation and fixation on conventional planes and surfaces to be inspected on many curved surfaces.

[0033] A card slot frame 12 is integrally cast and connected with the magnetic base; the card slot frame is a fence structure with one end open, and the opening of the card slot frame is equipped with a lock assembly for fastening the guide card; the lock assembly is preferably Non-magnetic metal material, easy to open and close when the magnetic base is magnetic. A U-shaped slot 12-1 is made along the inner edge of the fence (the groove depth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com