Flexible conductive composite film and preparation method thereof, and flexible pressure sensor and preparation method thereof

A pressure sensor, flexible conductive technology, applied in the field of sensors, can solve the problems of expensive equipment, achieve low cost, simple preparation process, and improve the effect of binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

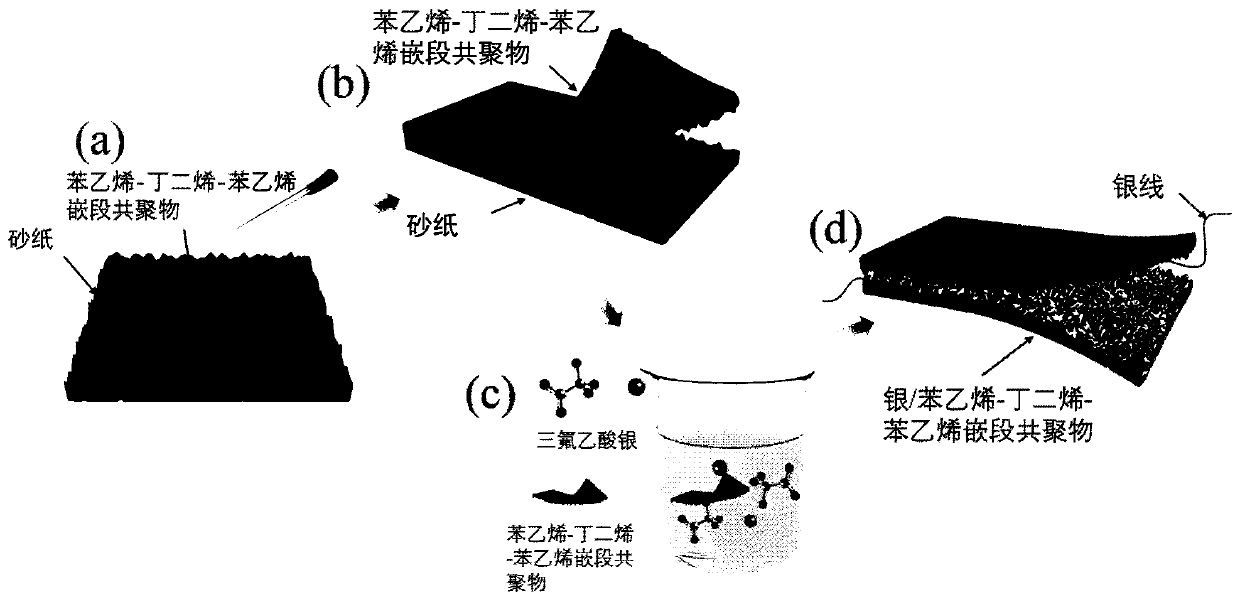

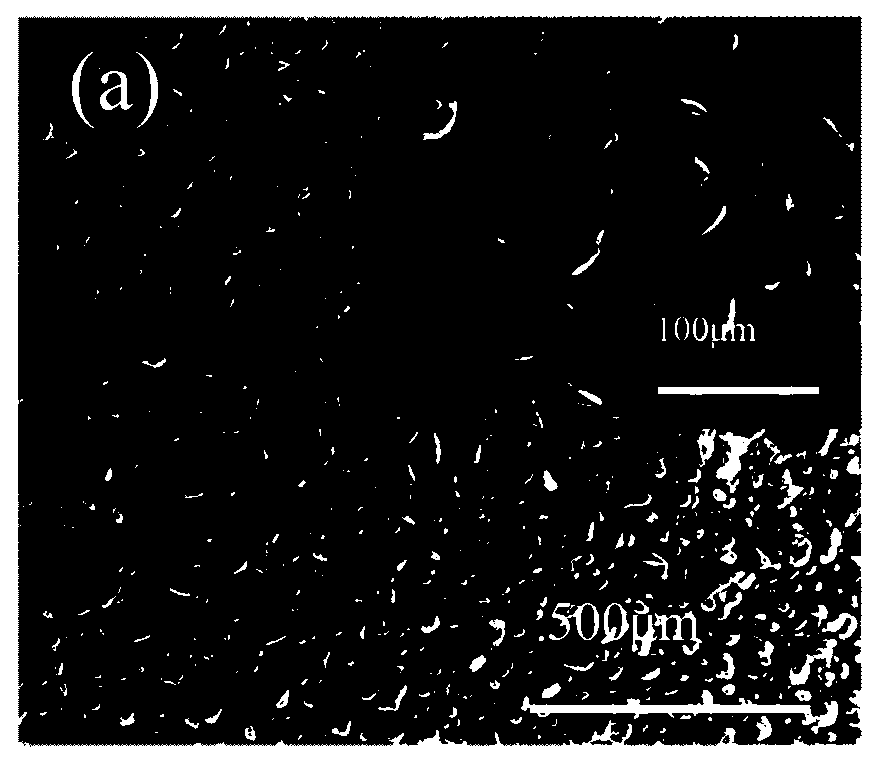

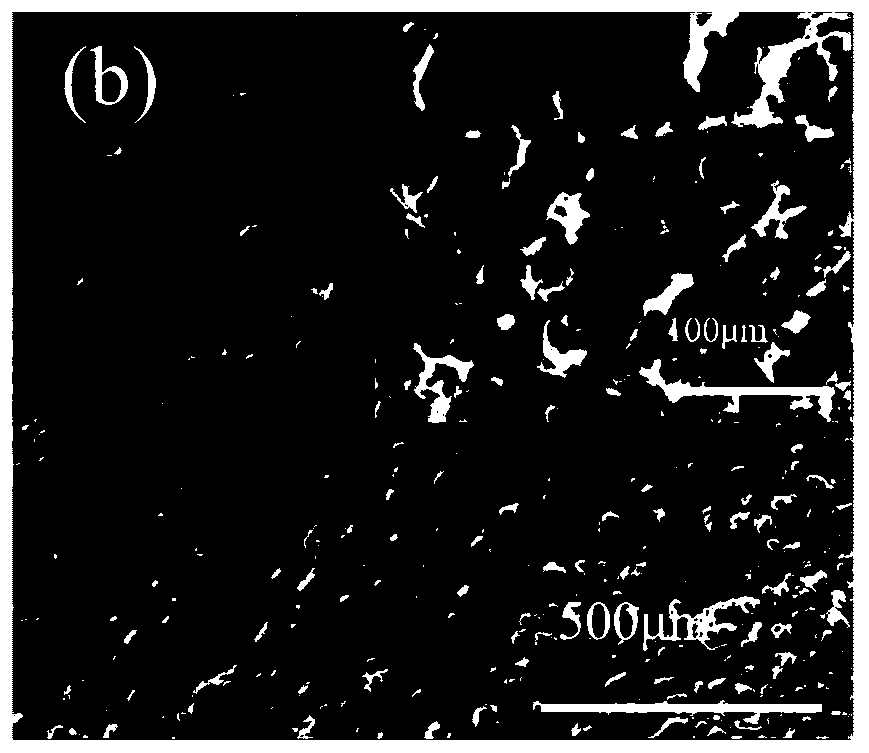

[0072] This embodiment provides a flexible pressure sensor, the preparation method of which includes the following steps (for the preparation flow chart, see figure 1 , the layered schematic diagram of the sensor see Figure 5 ):

[0073] (1) Cut 500-mesh sandpaper into a shape of 5cm×5cm for cleaning, and then use plasma treatment for 5 minutes before use.

[0074] (2) Dissolve the SBS particles in ethyl acetate solvent to configure a solution with a mass fraction of 20wt%, and then pour the SBS solution on the surface of the pretreated sandpaper, then spin coat it at a speed of 100rpm for 10s, and then place it on Dry in a blast oven at 50°C for 3h. The film-forming SBS polymer was slowly peeled off from the sandpaper surface to obtain a microstructured SBS flexible substrate.

[0075] (3) Place the SBS film in a silver trifluoroacetate / ethanol solution with a mass fraction of 10% for 15 minutes, use a hydrazine hydrate / ethanol solution with a mass fraction of 50% after d...

Embodiment 2

[0080] This embodiment provides a flexible pressure sensor, the preparation method of which includes the following steps:

[0081] (1) The microstructured silicon template (Chengdu Keshengda Guandian Technology Co., Ltd., 20*10*0.7) was cut into a shape of 1cm×1cm for cleaning, and then treated with plasma for 5 minutes before use.

[0082](2) Dissolve the SIS particles in ethyl acetate solvent to configure a solution with a mass fraction of 15wt%, and then pour the SIS solution on the surface of the pretreated silicon template, then spin-coat it at 100rpm for 10s, and then place it Dry in a blast oven at 50°C for 3h. The film-forming SIS polymer was slowly peeled off from the sandpaper surface to obtain a microstructured SIS flexible substrate.

[0083] (3) Place the SIS film in a silver trifluoroacetate / ethanol solution with a mass fraction of 15% for 15 minutes, and use a hydrazine hydrate / ethanol solution with a mass fraction of 65% after drying to obtain the SIS film sur...

Embodiment 3

[0086] This embodiment provides a flexible pressure sensor, the preparation method of which includes the following steps (for the preparation flow chart, see figure 1 ):

[0087] (1) The rose petals are cleaned, and then treated with plasma for 5 minutes before use.

[0088] (2) Dissolving the SBS particles in ethyl acetate solvent to configure a solution with a mass fraction of 20wt%, then pouring the SBS solution on the surface of the pretreated rose petals, then spin-coating for 10s at a speed of 100rpm, and then placing Dry in a blast oven at 50°C for 3h. The film-forming SBS polymer was slowly peeled off the surface of rose petals to obtain a microstructured SBS flexible substrate.

[0089] (3) Place the SBS film in a silver trifluoroacetate / ethanol solution with a mass fraction of 10% for 15 minutes, use a hydrazine hydrate / ethanol solution with a mass fraction of 50% after drying, and obtain a compound on the surface of the SBS film through a chemical reduction reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com