Laser processing morphological performance time-resolved differential confocal spectrum measurement method and device

A differential confocal and laser processing technology, applied in the direction of measuring devices, optical devices, scattering characteristics measurement, etc., can solve the problem of inability to realize simultaneous time-resolved measurement of material shape parameters and performance parameters in femtosecond processing, and inability to monitor material removal Problems such as instantaneous shape change process and femtosecond laser modification processing time are short, so as to improve the controllability and sample processing quality, improve the axial measurement accuracy and positioning accuracy, and achieve the effect of axial high-precision positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

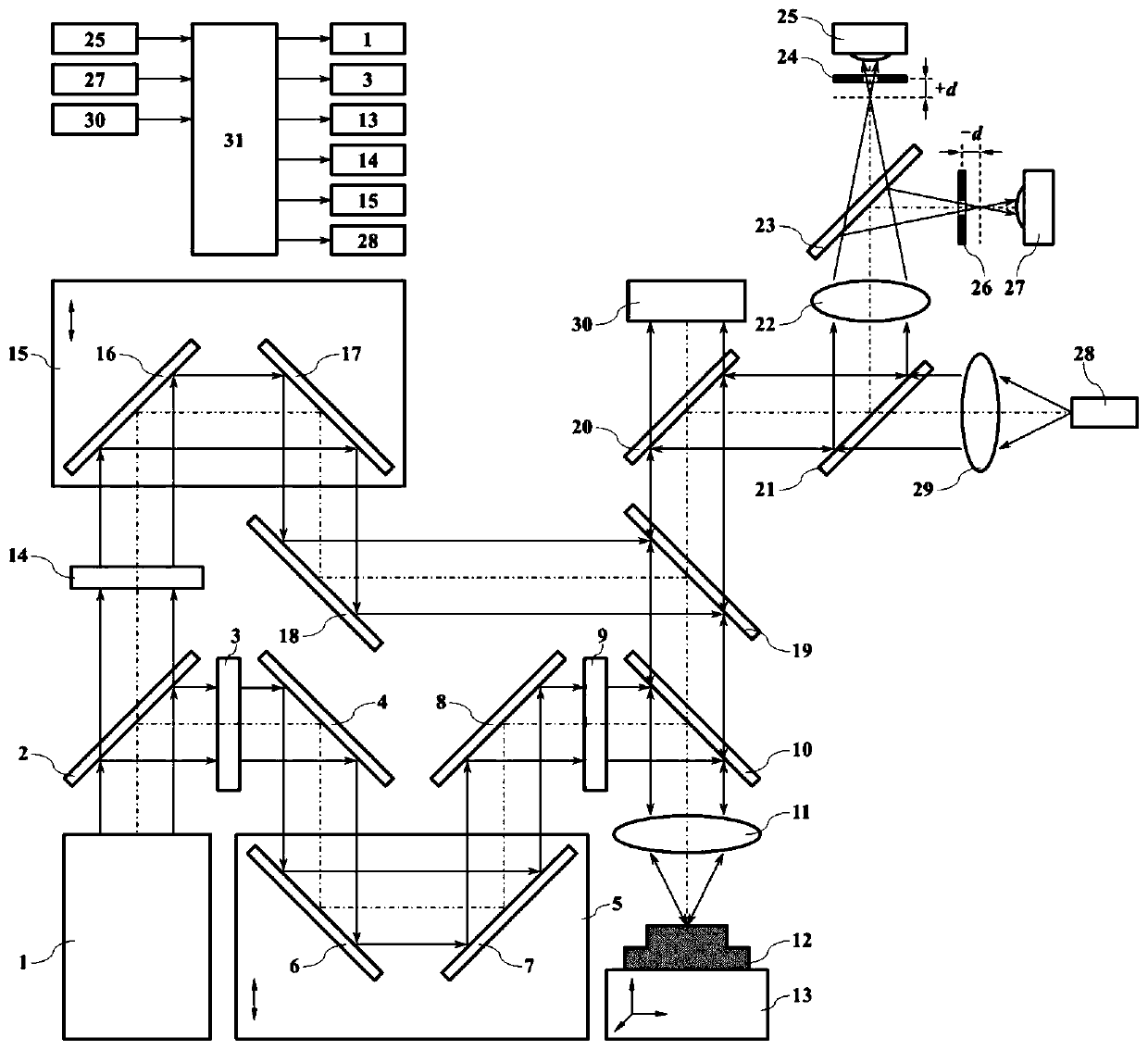

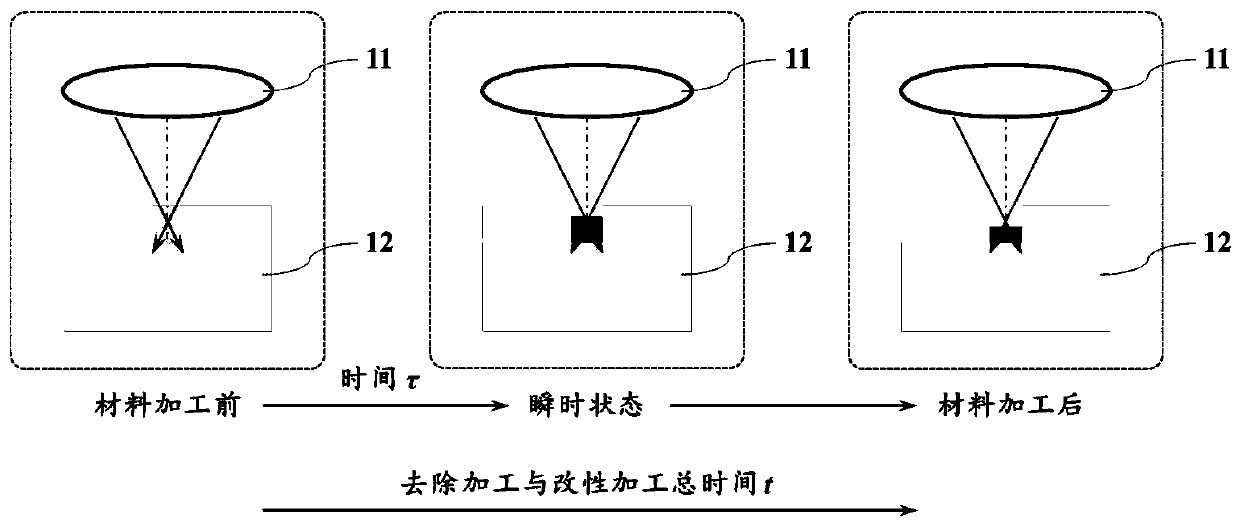

[0037] A time-resolved differential confocal spectrum measurement method for laser processing morphology and performance, using continuous laser differential confocal optical path to accurately position the material surface in the axial direction, using femtosecond laser to process materials, and using femtoseconds with different delay times The pulsed laser detects the Raman spectrum performance parameters of the material, and at the same time uses the differential confocal optical path to detect its morphological parameters. Repeat the above process of "continuous laser differential confocal positioning-femtosecond laser processing-delayed femtosecond laser Raman spectrum performance parameter detection-synchronous differential confocal morphological parameter detection" to simultaneously obtain the morphological parameters and The change process of performance parameters with time realizes the time-resolved measurement of material morphological parameters and performance par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com