High-energy-conservation, heat-insulation, sound-insulation and fireproof steel door

A fire-resistant, steel technology, applied in the field of steel doors, can solve the problems of not being able to bring about energy-saving effects, and cannot meet the requirements of heat preservation, sound insulation and fire resistance, etc., and achieve outstanding heat preservation effects, high energy-saving effects, and enhanced sealing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

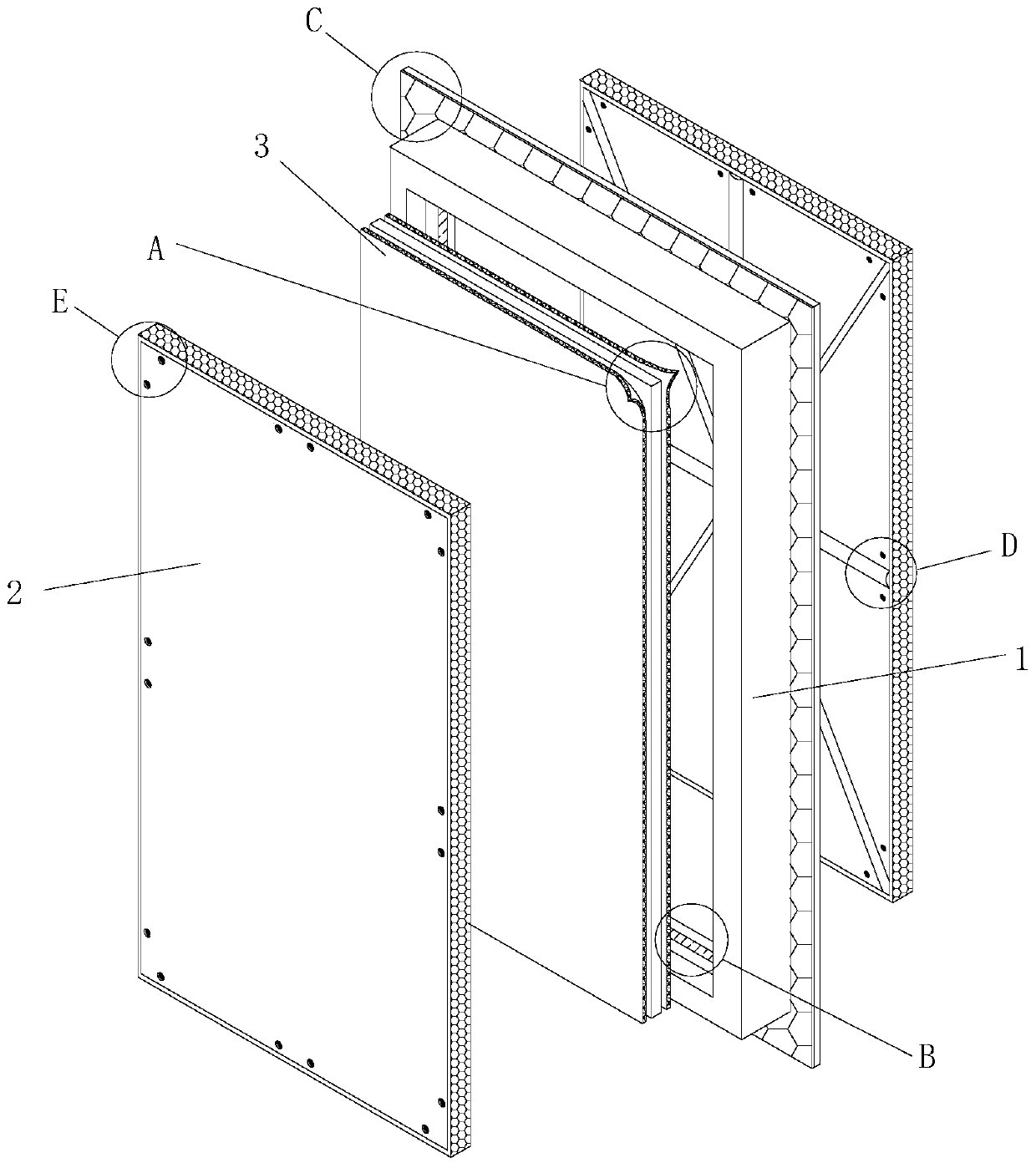

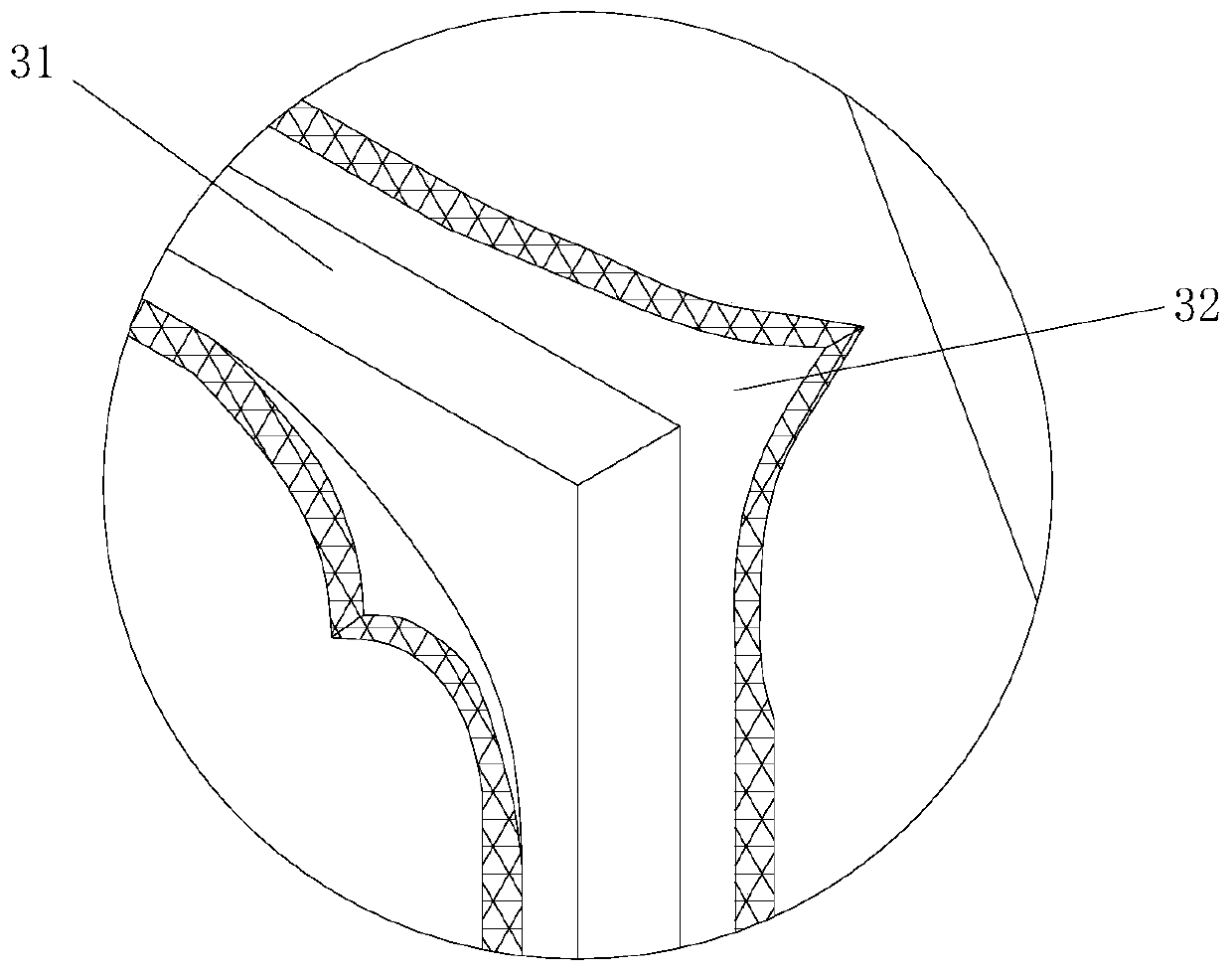

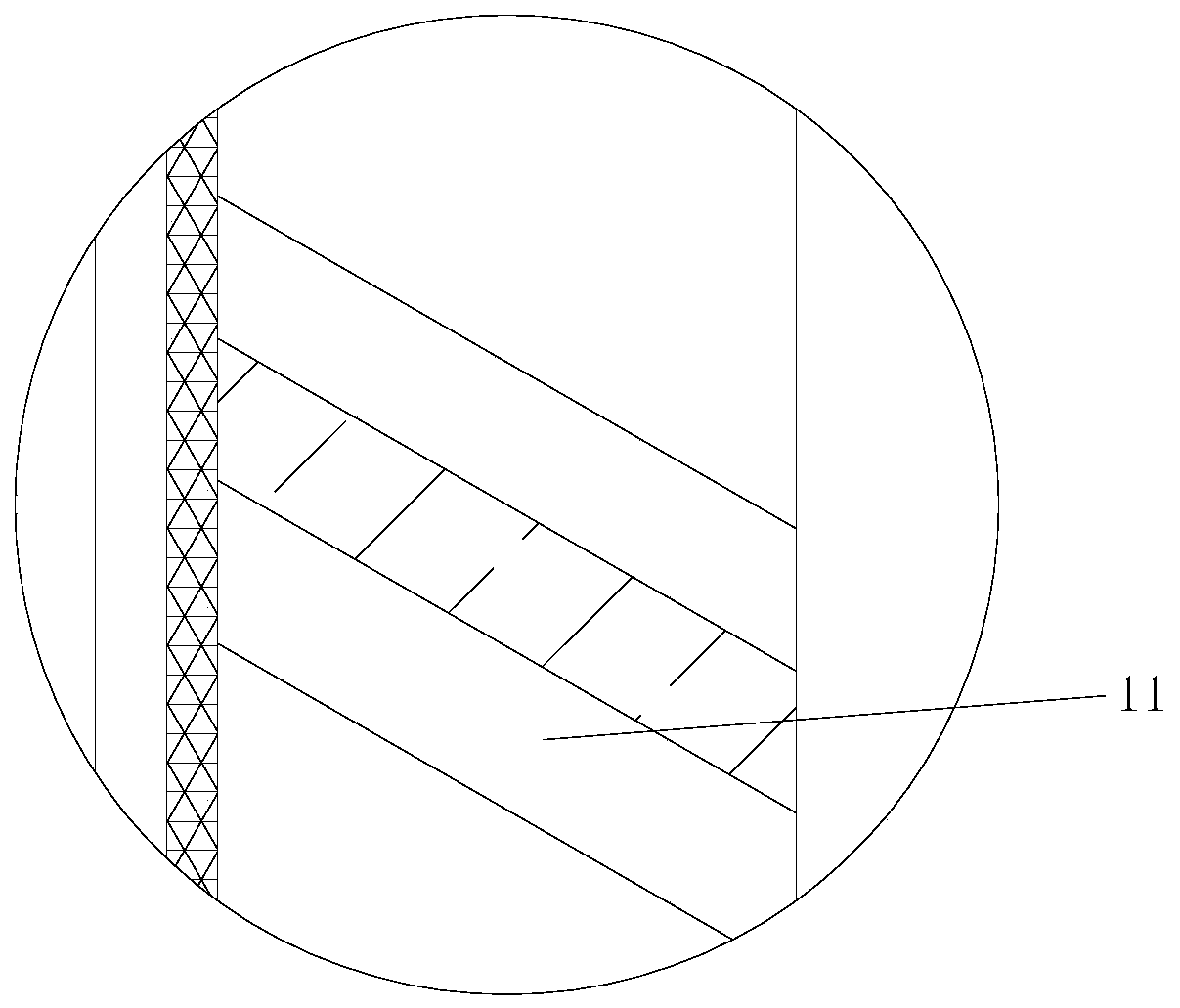

[0032] Embodiment 1, please refer to the attached figure 2 As shown, the technical solution of the present invention provides a high-energy-saving, heat-insulating, sound-insulating and fire-resistant steel door, which includes a door frame 1 and two door panels 2 respectively installed on the front and rear end faces of the door frame 1. The door frame 1 is rectangular The glass fiber reinforced polyurethane frame, the two door panels 2 are galvanized cold-rolled steel plates, and the outer surfaces of the two door panels 2 are painted with fireproof paint, the fireproof paint is mainly made of cement (Portland cement , magnesium oxychloride or inorganic high-temperature binder, etc.), aggregates (expanded vermiculite, expanded perlite, aluminum silicate fiber, mineral wool, rock wool, etc.), chemical additives (modifiers, hardeners, waterproofing agents, etc. ) and water, the inside of the door frame 1 is provided with a filling layer 3 between the two door panels 2, the fi...

Embodiment 2

[0033] Embodiment 2, please refer to the attached figure 2As shown, the inner surfaces of the two door panels 2 are all cast-welded with rice-shaped reinforcing ribs 21, and each rib section of the rice-shaped reinforcing ribs 21 is straight-sided arc-shaped. Design, so that the strength of each door panel 2 is improved, and the impact resistance is strengthened. There are several mounting holes 23 through the two door panels 2, and each two is a group, and each group is located one by one in each The ribs are close to both sides of the edge head of the door panel 2, and the outer opening of each of the mounting holes 23 is provided with a nut hidden groove 23a, and each of the two corresponding mounting holes 23 on the two door panels 2 Both are interspersed with hexagonal long screws 24, and two sets of flat pads 24a and sealing rubber rings 24b are respectively sleeved on the rod bodies at both ends of the hexagonal long screw rods 24, and the hexagonal long screw rods 24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com