Photocatalyst pillowcase, preparation method of photocatalyst pillowcase, and throw pillow

A photocatalyst and pillowcase technology, applied in separation methods, chemical instruments and methods, pillows, etc., can solve the problems of poor performance in the removal of air pollutants, reduced purification efficiency, and inability to infinitely adsorb, and achieve high practical value and avoid Wasteful, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

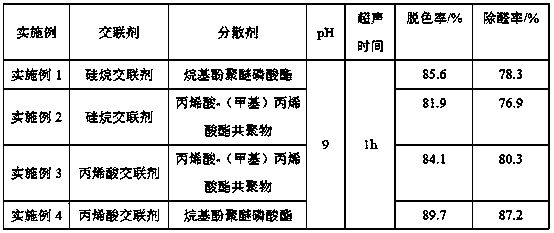

[0024] Embodiment 1~4 provides the method for textile loaded nano titanium dioxide, described method comprises the following steps:

[0025] Nano-titanium dioxide pretreatment: Weigh 2.0773g of nano-titanium dioxide particles, respectively add silane crosslinking agent or acrylic acid crosslinking agent whose mass is 30% of the mass of nano-titanium dioxide particles, and 10% of the mass of nano-titanium dioxide particles. Polyether phosphate or acrylic acid-(meth)acrylate copolymer, the specific ratio is shown in Table 1, then added to 500mL ethanol solution with a mass fraction of 20%, adjust the pH to 9, 30kHz ultrasonic treatment for 1h, and dry to obtain the surface Modified treated nano titanium dioxide particles.

[0026] Preparation of nano-titanium dioxide dispersion liquid: Weigh 1.5024 g of improved nano-titanium dioxide particles, add 0.8% fatty alcohol polyoxyethylene ether of nano-titanium dioxide particle quality and 0.6% epoxy ethylene ether penetrating agent o...

Embodiment 5~12

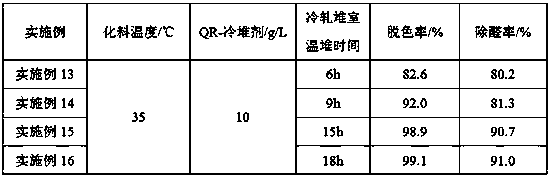

[0037] Embodiments 5 to 12 compared the functional fabrics obtained by cross-linking agents and dispersant dosages of different proportions, and compared the decolorization rate of rhodamine B decolorization test and the aldehyde removal rate experiment. The method comprises the following steps:

[0038] Nano-titanium dioxide pretreatment: Weigh 2.5057 g of nano-titanium dioxide particles, add acrylic acid crosslinking agent whose mass is 10%, 30%, and 40% of the mass of nano-titanium dioxide particles, and 10%, 20%, and 40% of the mass of nano-titanium dioxide particles. 30% alkylphenol polyether phosphate, the specific ratio is shown in Table 2, then added to 500mL ethanol solution with a mass fraction of 20%, adjust the pH to 9, 30kHz ultrasonic treatment for 1h, and dry to obtain surface modified Nano titanium dioxide particles.

[0039] Preparation of nano-titanium dioxide solution: Weigh 1.9924 g of improved nano-titanium dioxide particles, add 0.8% fatty alcohol polyoxy...

Embodiment 13~16

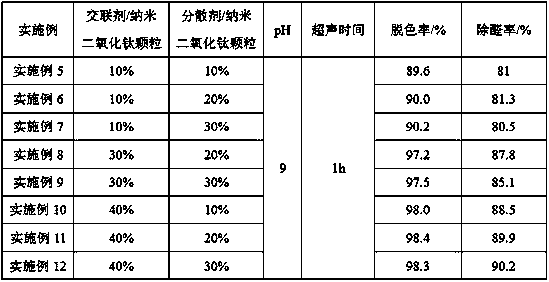

[0049] Embodiments 13 to 16 are basically similar to the method of embodiment 11, the difference is that in the step cold rolling process, the cold rolling process adopted: the cloth processed by the load is placed in the pre-treatment liquid for padding for chemical , the material temperature is 45°C, and the padding pretreatment liquid includes 35g / L of QR-cold pile agent and 10g / L of 100% hydrogen peroxide. The cold pad batch was washed at room temperature for 6, 9, 15, and 18 hours respectively, washed twice at 95°C, once at 80°C, twice at 15°C, and finally dried at 105°C to obtain a functional cloth.

[0050] The load fastness test was carried out to the functional cloth of loaded nano-titanium dioxide obtained in Examples 13-16. The specific test method is to put the functional cloth obtained in the above-mentioned embodiment into the steel used for testing the color fastness to washing in the textile industry respectively. In the cup, add an appropriate amount of steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com