A kind of preparation method of high temperature corrosion resistant mg-pb-al-b nuclear shielding material

A mg-pb-al-b, high-temperature corrosion-resistant technology, applied in shielding, metal material coating technology, nuclear engineering, etc., can solve problems such as prone to corrosion, achieve enhanced absorption effect, excellent corrosion resistance, and improve Effect of nuclear shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

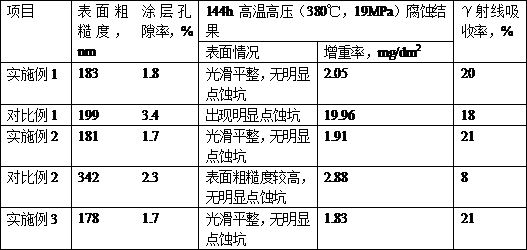

Examples

Embodiment 1

[0023] A preparation method of a high-temperature corrosion-resistant Mg-Pb-Al-B nuclear shielding material, comprising the following operation steps:

[0024] (1) Put Bi 2 O 3 , V 2 O 5 , Y 2 O 3 After mixing evenly at a mass ratio of 5:5:1, add it to a ball mill, add acetone to it, ball mill, dry it, and sinter at 950°C for 2 hours to obtain mixed rare earth powder, in which acetone and Bi 2 O 3 The volume-to-mass ratio is 1ml:4g,;

[0025] (2) After mixing lead fluoride and barium fluoride in a mass ratio of 49:35, and sintering in a vacuum environment, PbF is obtained 2 / BaF 2 For eutectic powder, during sintering treatment, the temperature is 1080℃, and the sintering treatment time is 30min;

[0026] (3) In parts by weight, combine 38 parts of magnesium powder, 11 parts of lead powder, 25 parts of aluminum powder, 19 parts of boron-containing master alloy, 2 parts of mixed rare earth powder, and 1 part of PbF 2 / BaF 2 The eutectic powder is added to the ball mi...

Embodiment 2

[0030] A preparation method of a high-temperature corrosion-resistant Mg-Pb-Al-B nuclear shielding material, comprising the following operation steps:

[0031] (1) Put Bi 2 O 3 , V 2 O 5 , Y 2 O 3 After mixing uniformly at a mass ratio of 8:9:1, it was added to a ball mill, and acetone was added to it. After ball milling, drying, and sintering at 970°C for 2.5 hours, mixed rare earth powder was obtained, wherein acetone and Bi 2 O 3 The volume to mass ratio is 1ml:5g,;

[0032] (2) After mixing lead fluoride and barium fluoride in a mass ratio of 49:35, and sintering in a vacuum environment, PbF is obtained 2 / BaF 2 Eutectic powder, when sintering, the temperature is 1080℃, and the sintering time is 35min;

[0033] (3) In parts by weight, combine 42 parts of magnesium powder, 13 parts of lead powder, 28 parts of aluminum powder, 21 parts of boron-containing master alloy, 4 parts of mixed rare earth powder, and 3 parts of PbF 2 / BaF 2 The eutectic powder is added to ...

Embodiment 3

[0037] A preparation method of a high-temperature corrosion-resistant Mg-Pb-Al-B nuclear shielding material, comprising the following operation steps:

[0038] (1) Put Bi 2 O 3 , V 2 O 5 , Y 2 O 3 After mixing uniformly at a mass ratio of 10:10:1, it was added to a ball mill, and acetone was added to it. After ball milling, drying, and sintering at 980°C for 3 hours, mixed rare earth powder was obtained, wherein acetone and Bi 2 O 3 The volume to mass ratio is 1ml:6g,;

[0039] (2) After mixing lead fluoride and barium fluoride in a mass ratio of 49:35, and sintering in a vacuum environment, PbF is obtained2 / BaF 2 Eutectic powder, when sintering, the temperature is 1080℃, and the sintering time is 40min;

[0040] (3) In parts by weight, 45 parts of magnesium powder, 16 parts of lead powder, 30 parts of aluminum powder, 24 parts of boron-containing master alloy, 6 parts of mixed rare earth powder, and 4 parts of PbF 2 / BaF 2 The eutectic powder is added to the ball m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com