A kind of high-entropy alloy immersion silver composite material and its preparation method and application

A high-entropy alloy and composite material technology, applied in the field of high-entropy alloy immersion silver composite material and its preparation, can solve the problem of short life, low friction coefficient of high-entropy alloy immersion silver composite material, wear resistance, poor sealing performance, poor reliability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

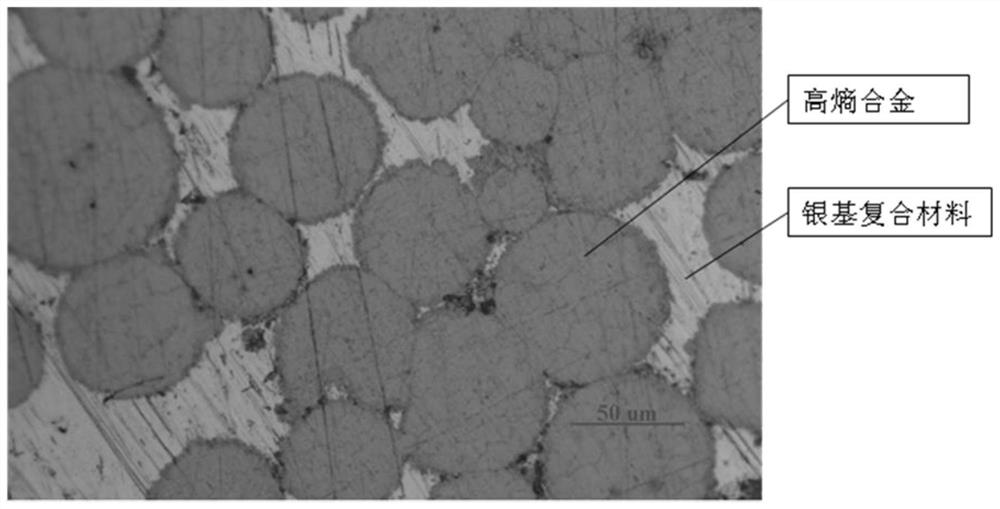

[0025] The invention provides a method for preparing a high-entropy alloy immersion silver composite material, comprising the following steps:

[0026] (1) Under vacuum conditions, AlCoCrFeNi high-entropy alloy spherical powder is sintered to obtain a high-entropy alloy material; the particle size of the AlCoCrFeNi high-entropy alloy spherical powder is 30-200 μm;

[0027] (2) After the high-entropy alloy material and the silver-based composite powder are vacuum-encapsulated, sintering is carried out to obtain a high-entropy alloy-impregnated silver composite material;

[0028] The silver-based composite powder is prepared from components comprising the following parts by mass:

[0029] 80-90 parts of Ag powder, 5-15 parts of BN powder, SiO 2 Powder 0.5~5 parts, CaF 2 Powder 0~5 parts, BaF 2 0-5 parts of ZnO powder and 0-1 part of ZnO powder.

[0030] In the present invention, unless otherwise specified, the raw materials used are conventional commercially available produc...

Embodiment 1

[0053] (1) Weigh 54g of Al powder, 118g of Co powder, 104g of Cr powder, 112g of Fe powder, and 118g of Ni powder, put them into a ball mill pot, and mix them in the ball mill. The particle size of the powder is 50-200 μm. The powder volume ratio is 2:1, the diameter of the grinding ball is 10mm and 5mm, the volume ratio of the two kinds of grinding balls is 2:1, the speed of the ball mill is 400rpm, and the grinding time is 40h to obtain the mixed powder;

[0054] (2) Prepare the mixed powder into AlCoCrFeNi high-entropy alloy spherical powder in metal vacuum atomization equipment;

[0055] (3) classify the obtained AlCoCrFeNi high-entropy alloy spherical powder with a 38 μm sampling sieve and a 76 μm sampling sieve, and select AlCoCrFeNi high-entropy alloy spherical powder with a particle size of 38 to 76 μm for use;

[0056] (4) The AlCoCrFeNi high-entropy alloy spherical powder obtained in step (3) is packed into a mould, and sintered in a vacuum two-way pressure furnace w...

Embodiment 2

[0064] (1) Weigh 14g of Al powder, 125g of Co powder, 116g of Cr powder, 120g of Fe powder, and 125g of Ni powder, put them into a ball mill pot, and mix them in the ball mill. The particle size of the powder is 50-200 μm. The powder volume ratio is 2:1, the diameter of the grinding ball is 10mm and 5mm, the volume ratio of the two kinds of grinding balls is 2:1, the speed of the ball mill is 400rpm, and the grinding time is 24h to obtain the mixed powder;

[0065] (2) Prepare the mixed powder into AlCoCrFeNi high-entropy alloy spherical powder in metal vacuum atomization equipment;

[0066] (3) Classify the obtained AlCoCrFeNi high-entropy alloy spherical powder with a 76 μm sampling sieve and a 105 μm sampling sieve, and select AlCoCrFeNi high-entropy alloy spherical powder with a particle size of 78-105 μm;

[0067] (4) The AlCoCrFeNi high-entropy alloy spherical powder obtained in step (3) is packed into a mould, and sintered in a vacuum two-way pressure furnace with a pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com