Anisotropic conductive adhesive and preparation method thereof

An anisotropic, conductive adhesive technology, applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems of high material cost and high processing cost, and achieve improved application range, strong bonding strength, and low contact The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also discloses a preparation method for the above-mentioned anisotropic conductive adhesive, which can be used to prepare the anisotropic conductive adhesive in the embodiment of the present invention. The preparation method includes:

[0031] Step a. preparing low-melting-point metal conductive particles of 0.5-100 microns;

[0032] Wherein, the low melting point metal conductive particles are in the state of metal droplets or metal powder;

[0033] Step b. Stir and mix the curable resin and the low-melting-point metal conductive particles according to a certain mass ratio for 0.1-10 hours to form a uniformly mixed liquid to form a thermosetting anisotropic conductive adhesive.

[0034] Wherein, the method of preparing low-melting-point metal conductive particles in step a can adopt traditional micronization processing technology, and can also adopt the following methods:

[0035] Step a1. Put a certain mass of molten metal with a low melting poi...

Embodiment 1

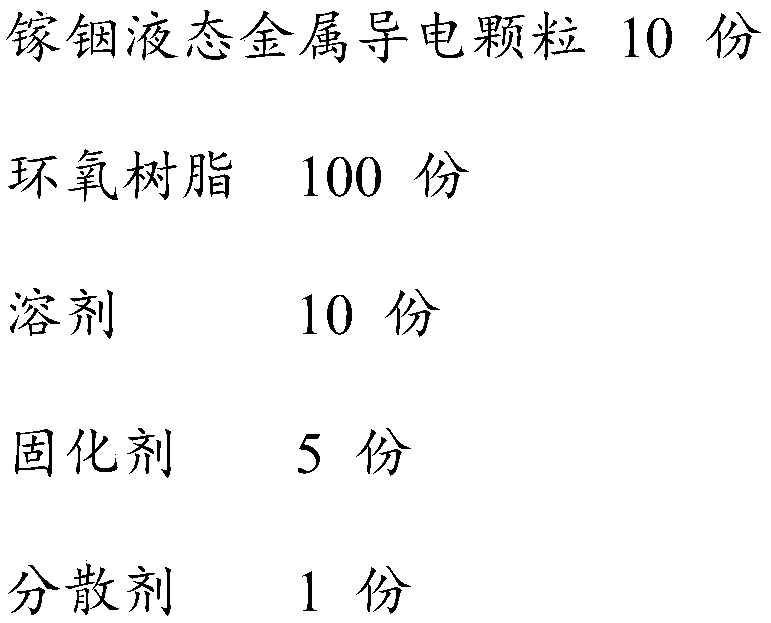

[0070] Embodiment 1: A heat-cured anisotropic conductive adhesive, the proportion of each component is as follows:

[0071]

[0072] The preparation process of the anisotropic conductive adhesive is as follows:

[0073] a. Stir the liquid metal Ga79In21 (melting point 16° C.) in absolute ethanol at a speed of 1000 r / min for 2 hours by using the liquid phase stirring method to obtain liquid metal conductive droplets with an average particle size of about 80 microns;

[0074] b. Mix all materials except liquid metal conductive particles according to the formula, and stir at a speed of 800r / min for 0.2h;

[0075] c. Mix the liquid metal conductive droplets obtained in step a with the mixture obtained in step b in proportion, and stir at a speed of 800r / min for 0.5h to obtain a mixed solution in which the metal conductive droplets are uniformly dispersed.

[0076] Using the above-mentioned mixed solution as the interconnection material, the flip chip (0.6×0.6mm2, RFID UHF Chip...

Embodiment 2

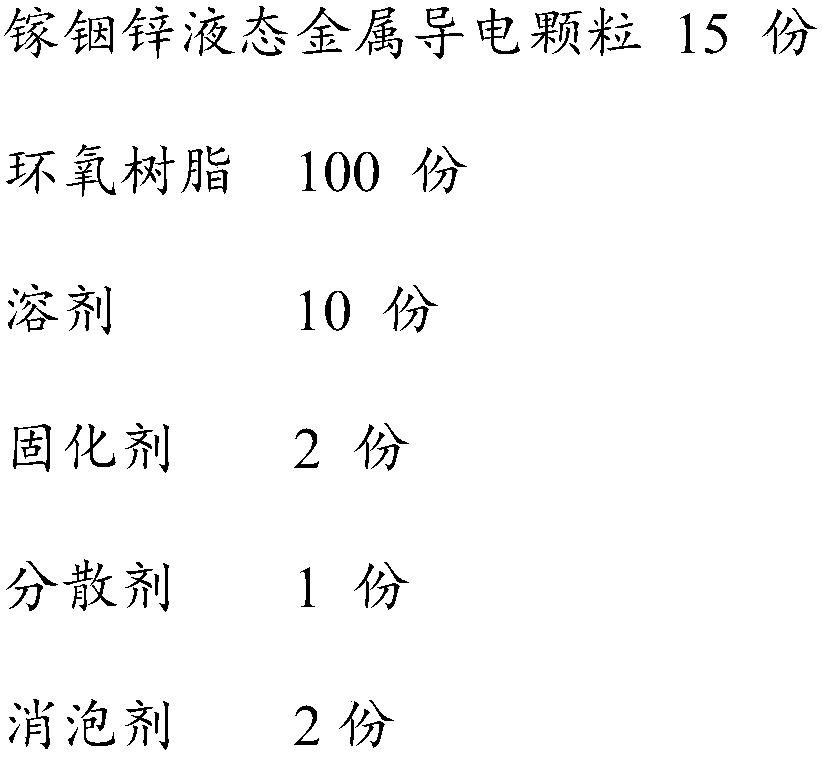

[0077] Embodiment 2: a kind of anisotropic conductive glue, each component distribution ratio (mass) is as follows:

[0078]

[0079] The preparation process of the anisotropic conductive adhesive is as follows:

[0080] a. Ultrasonic treatment of liquid metal (Ga67In20Zn13, melting point 11° C.) in isopropanol for 0.5 h by ultrasonic dispersion method to obtain liquid metal conductive droplets with an average particle size of about 2 microns;

[0081] b. Mix all materials except liquid metal conductive particles according to the formula, and stir for 1 hour at a speed of 800r / min;

[0082] c. Mix the liquid metal conductive droplets obtained in step a with the mixture obtained in step b in proportion, and stir at a speed of 800r / min for 0.5h to obtain a mixed solution in which the metal conductive droplets are uniformly dispersed.

[0083] Use the mixed solution prepared above as the interconnection material, and mount the flip chip (0.6×0.6mm2, RFID UHF Chip) on Al / coated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com