Pseudolaric acid B polylactic acid dispersion

A technology of acetic acid polylactic acid and eucalyptus acetic acid, which is applied in the field of preparation of pharmaceutical dispersions, can solve the problems of difficulty in applying long-term treatment of onychomycosis, easy crystallization and precipitation of eucalyptus acetic acid, poor medication compliance of patients, etc., and achieves reliable inhibition. Bacterial effect, treatment of bacterial infection, good biocompatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 100g of polylactic acid fine powder, put it in a spherical flask, add 100ml 80% ethanol to suspend, then add 70mg of Vitex acetic acid, heat and reflux in a water bath until the Vitex acetic acid dissolves, cool down to 45°C, and evaporate under reduced pressure Solvent, grind the residue and transfer it to a mill for grinding and crushing, and pass through an 80-mesh pharmacopoeia sieve to obtain the product.

Embodiment 2

[0020] Weigh 100g of polylactic acid fine powder, put it in a spherical flask, add 100ml of absolute ethanol to suspend, then add 1.4g of Vitex acetic acid, stir and dissolve at room temperature, heat in a water bath to 42°C, evaporate the solvent under reduced pressure, and remove the residual The material is transferred to a ball mill for grinding and crushing, and passed through a 100-mesh pharmacopoeia sieve.

experiment example 1

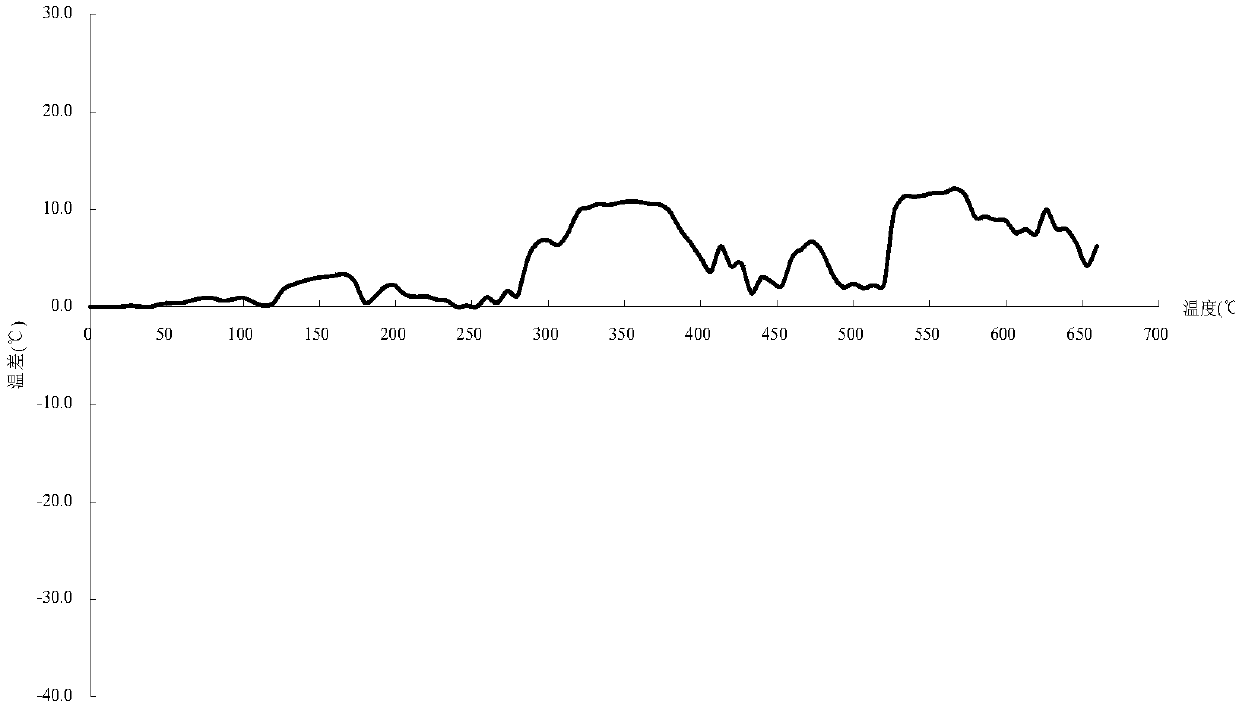

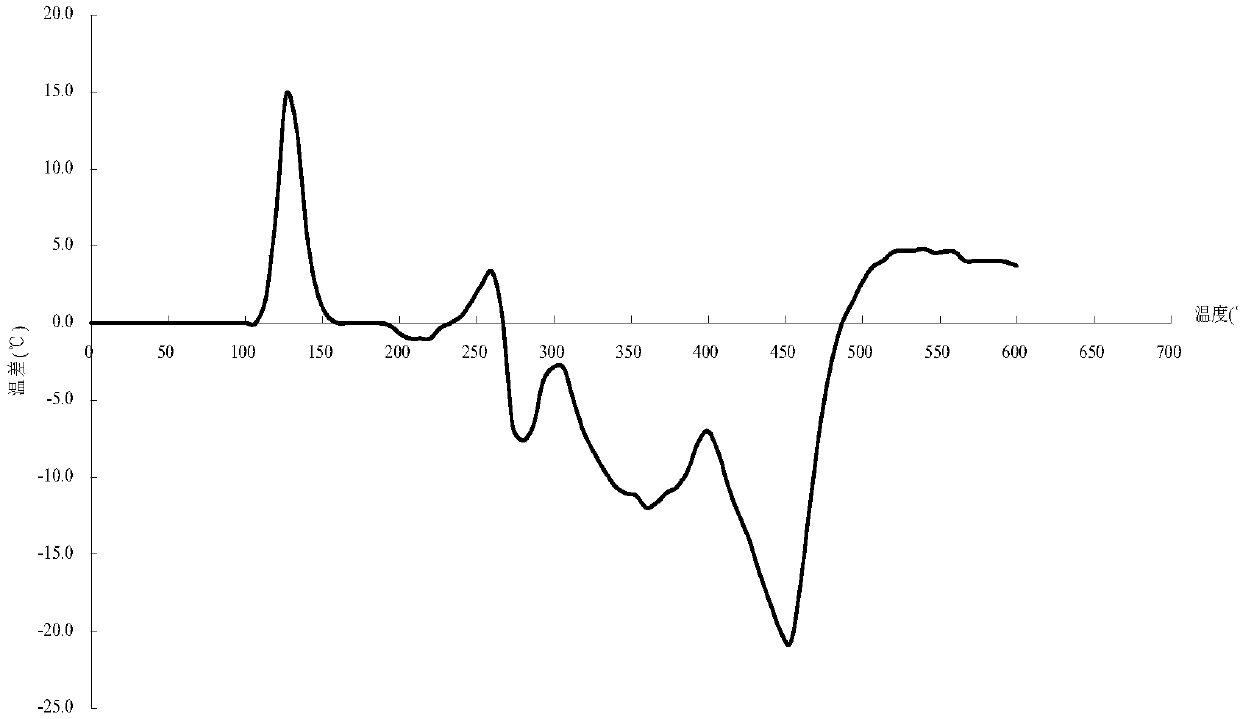

[0022] Using alumina as a reference, weigh the same amount of polylactic acid fine powder and tertiary acid polylactic acid fine powder, and conduct differential calorimetry scanning from room temperature to 650°C respectively. It can be seen that there are multiple jagged differences in the scanning spectrum of polylactic acid. Thermal peaks, such as 180°C, 267°C, 280°C, 307°C, 407°C, 433°C, 453°C, etc., are mostly small peaks mixed together, showing the molecular characteristics of polymers; scanning of the fine powder of polylactic acid loaded on the bark of Vitex There are obviously four differential thermal peaks in the spectrum, which are 127°C, 280°C, 360°C, and 453°C, respectively, which are sharp peaks, suggesting that Vitex acetic acid may exist in the form of microcrystals in the polylactic acid carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com