Device and process for preparing methane by coal chemical looping catalytic gasification based on calcium oxide

A chemical chain catalytic gas, calcium oxide technology, applied in gasification process, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of low methane yield and large catalyst usage and other problems, to achieve the effect of realizing self-heating balance, speeding up the gasification reaction rate and facilitating separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

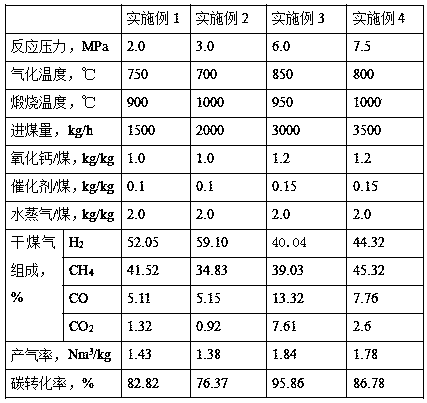

Embodiment 1

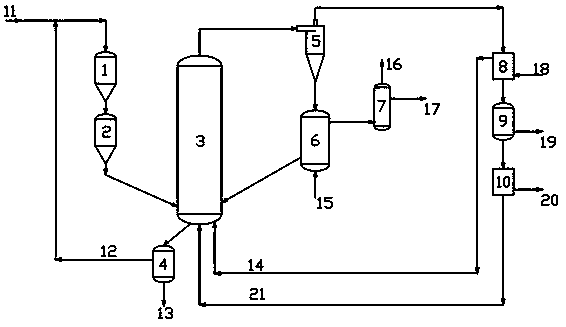

[0037] A calcium oxide-based coal chemical looping catalytic gasification methane production process, comprising the following steps:

[0038]1) Put coal, catalyst, and calcium oxide reaction raw materials 11 of different particle sizes into the fluidized bed gasification reactor 3 sequentially through the balance lock hopper 1 and the feed hopper 2, and the superheated steam 14 and the circulating methane-lean gas 21 are fed into the fluidized bed gasification reactor 3. The bottom of the fluidized bed gasification reactor 3 is passed through, and catalytic gasification, water vapor shift, and methanation reactions occur in the fluidized bed gasification reactor 3 to generate gas rich in methane; Carbon dioxide undergoes carbonation reaction to generate calcium carbonate, and the released reaction heat supplements the heat required for gasification reaction to achieve the self-heating balance of the system;

[0039] 2) The methane-enriched gas carries calcium carbonate and se...

Embodiment 2

[0047] use figure 1 Shown technological process, operation steps are as embodiment 1.

[0048] Ningxia lignite is used, and the particle size of pulverized coal is 3-5 mm. The particle size of calcium oxide is 100-200 μm. The catalyst is an alumina-supported catalyst, its mass percentage is: K: 20%, Ca: 5%, Fe: 15%, and the particle size of the catalyst is 600-800 μm.

[0049] The operating pressure is 3.0 MPa, the operating temperature of the gasification reactor is 700 °C, and the operating temperature of the calcination reactor is 1000 °C.

Embodiment 3

[0051] use figure 1 Shown technological process, operation steps are as embodiment 1.

[0052] Shenmu bituminous coal is used, and the coal powder particle size is 3-5 mm. The particle size of calcium oxide is 200-300 μm. The catalyst is an alumina-supported catalyst, its mass percentage is: K: 25%, Ca: 5%, Fe: 10%, and the particle size of the catalyst is 600-800 μm.

[0053] The operating pressure is 6.0 MPa, the operating temperature of the gasification reactor is 850 °C, and the operating temperature of the calcination reactor is 950 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com