Biomass air-water vapour gasifier

A water vapor and gasifier technology, applied in the field of gasifiers, can solve the problems of energy consumption, high investment cost, low economic benefits, etc., and achieve the effect of self-heating balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

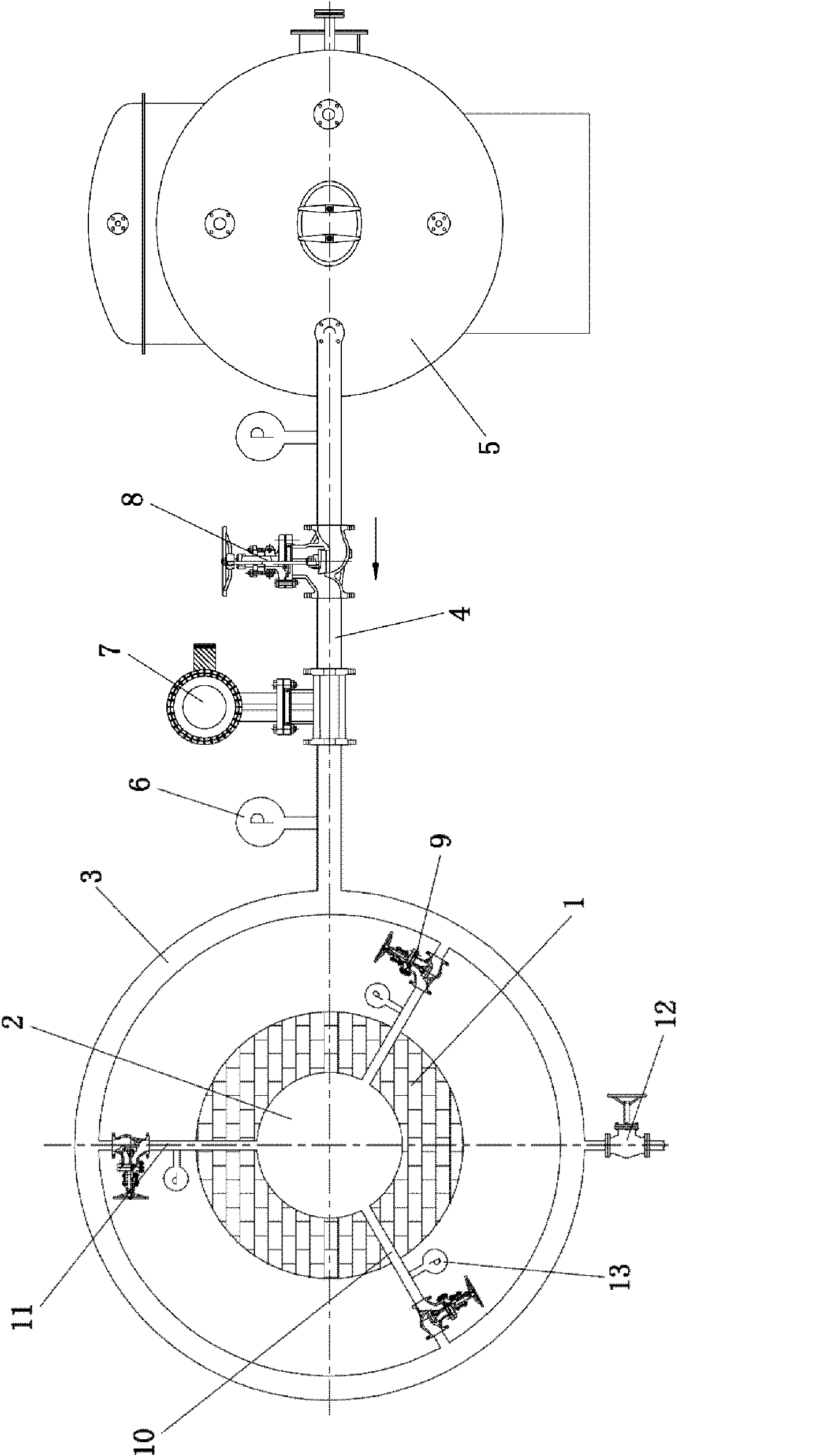

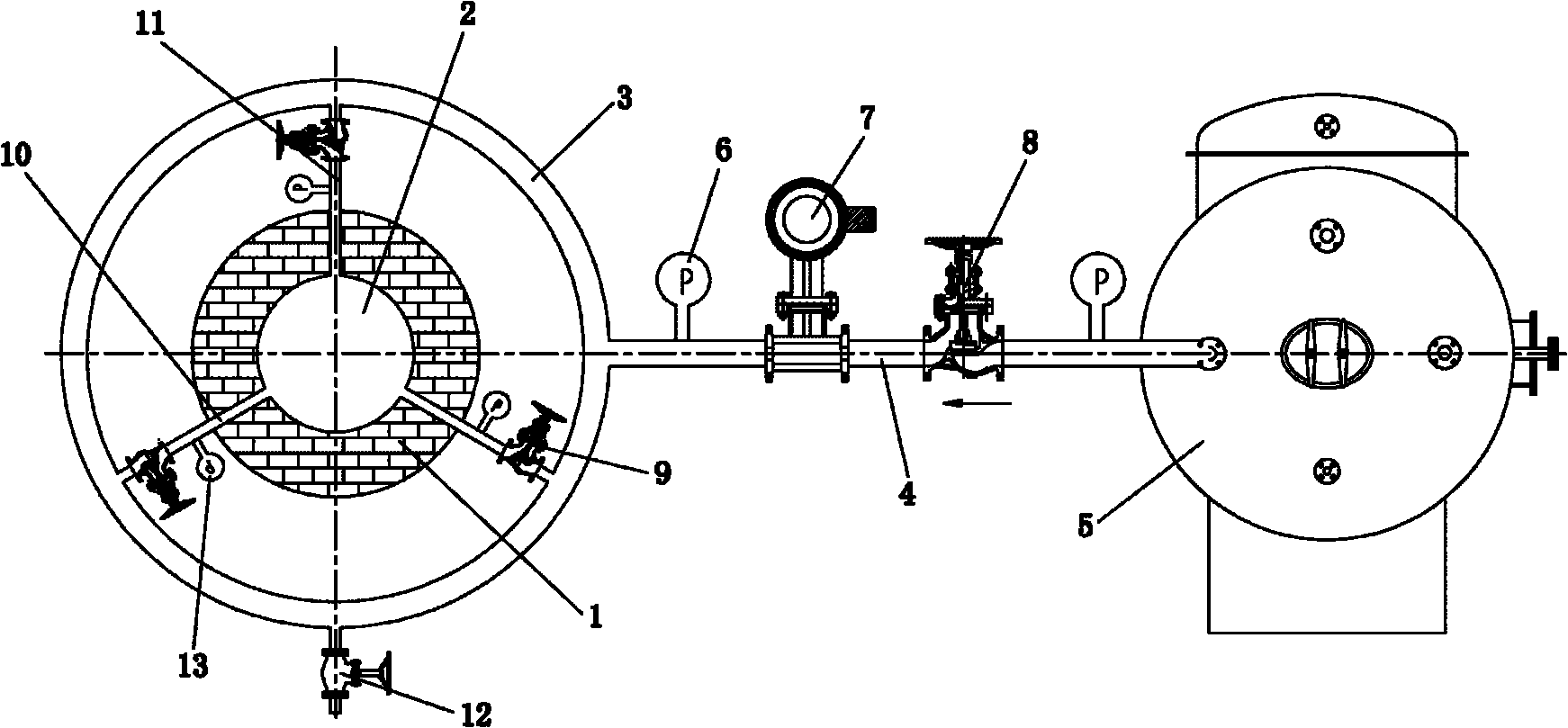

[0018] Such as figure 1 As shown, the gasifier of the present invention is a 0.5 ton / hour gasifier, and the fluidized bed is the best. The furnace body 1 of the gasifier is connected with a water steam pipeline assembly to provide high-temperature water vapor to the combustion chamber 2 in the furnace body 1 . The combustion chamber is a hollow cylindrical body. The wall body of the furnace body 1 (combustion chamber) offers three through-holes 10, and the through-holes 10 are circumferentially evenly arranged on the cross section of the furnace body 1, and the positions of the through-holes 10 are located in the combustion layer. The steam pipeline assembly is composed of a three-way steam pipeline 11 , a steam distributor 3 and a steam main pipe 4 . The steam distributor 3 is in the shape of a circle, and its inner circle side is connected with three steam pipelines 11, each steam pipeline 11 is also arranged uniformly around the circumference, and each steam pipeline 11 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com