GGH (gas-gas heater) heating system capable of preventing wet smoke from corroding and blocking pipeline and application method

A heating system, wet flue gas technology, applied in combustion methods, lighting and heating equipment, emission prevention, etc., can solve the problems of high equipment operating costs, GGH corrosion and blockage, short equipment commissioning time, etc., to increase the overall length , to achieve the effect of self-heating balance of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

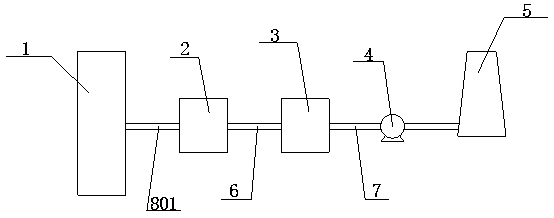

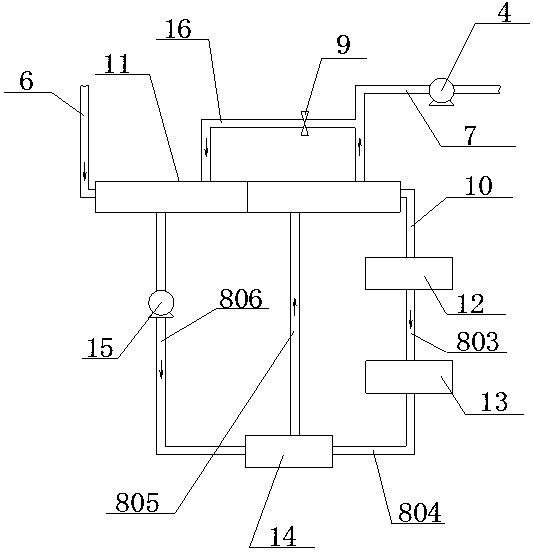

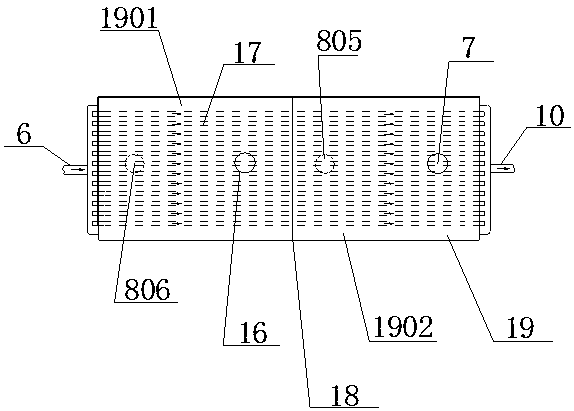

[0040] Such as Figure 1 to Figure 3 As shown, the GGH heating system to prevent wet flue gas from corroding and blocking pipes includes a coal-fired boiler 1, a dust collector 2, a flue gas reheating structure 3, and a smoke exhaust device 5. The exhaust port of the coal-fired boiler 1 passes through a first connecting pipe 801 It communicates with the air inlet of the dust collector 2, the exhaust port of the dust collector 2 communicates with the air inlet of the flue gas reheating structure 3 through the smoke inlet pipe 6, and the exhaust end of the flue gas reheating structure 3 passes through the smoke pipe 7 Connected with the air inlet of the smoke exhaust device 5, the flue gas reheating structure 3 includes a heat exchanger 11, a desulfurization device 12, a demister 13 and a flash evaporator 14, and the heat exchanger 11 is provided with a heat exchange chamber 19 and a heat exchange chamber. Pipe 17, the heat exchange pipe 17 is located in the heat exchange chambe...

Embodiment 2

[0043] Based on Embodiment 1, the heat exchange tubes 17 are side-by-side straight tubes, and the inlet and exhaust ports of the heat exchange tubes 17 are located on both sides of the heat exchanger 11 .

[0044] In use, the heat exchange tubes are arranged as side-by-side straight tubes, and the total length of the heat exchange tubes is increased so that there is enough space to transfer more heat.

Embodiment 3

[0046] Based on Embodiment 2, a partition plate 18 is provided in the heat exchange chamber 19, and the partition plate 18 is perpendicular to the heat exchange tube 17, and the heat exchange tube 17 passes through the partition plate 18, and the partition plate 18 divides the heat exchange chamber 19 into a first heat exchanger. The heat chamber 1901 and the second heat exchange chamber 1902.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com