Rotor of motor and motor

A rotor and rotor shaft technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve problems such as lack of heat dissipation, achieve good heat dissipation effect, increase the overall length, and improve the connection stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

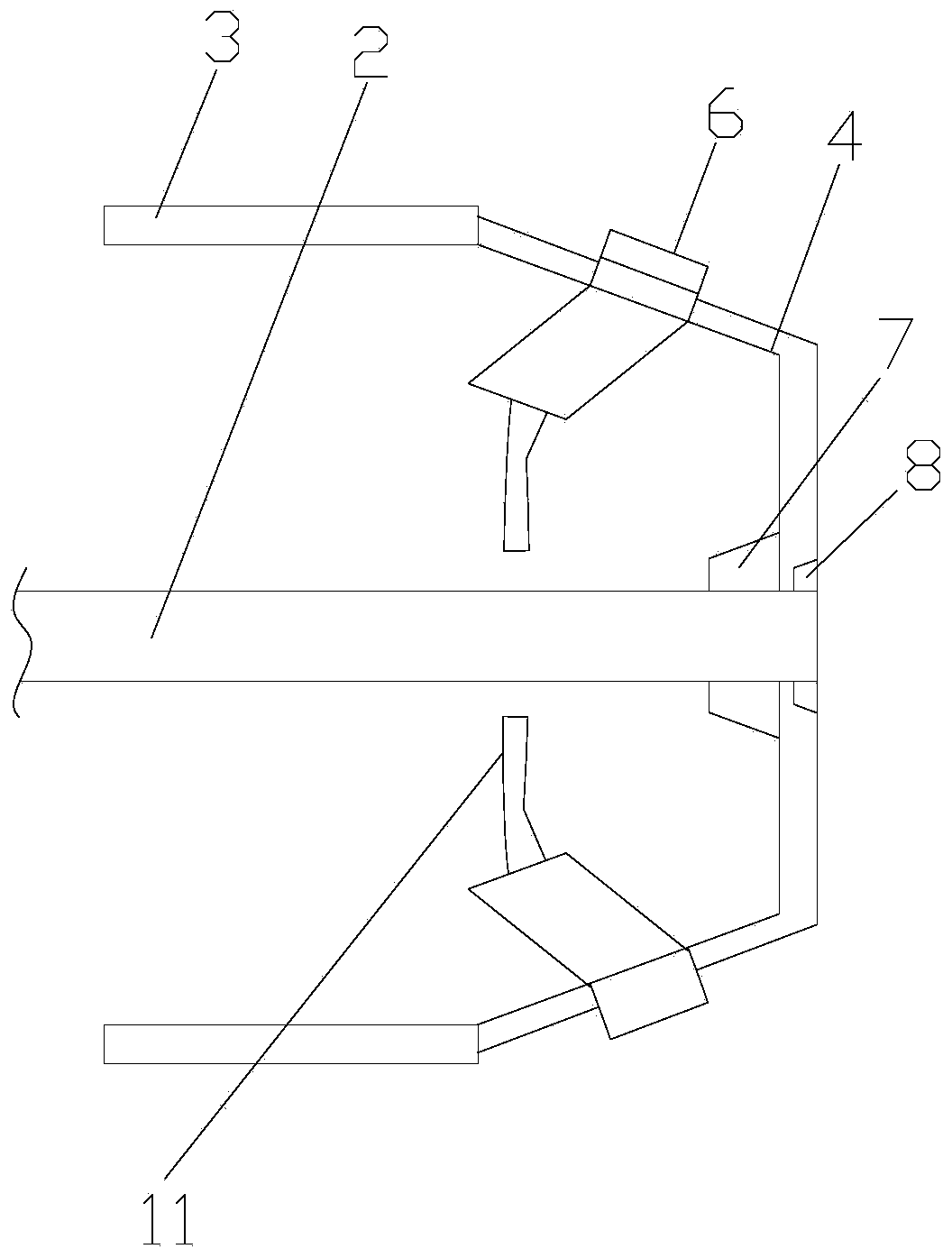

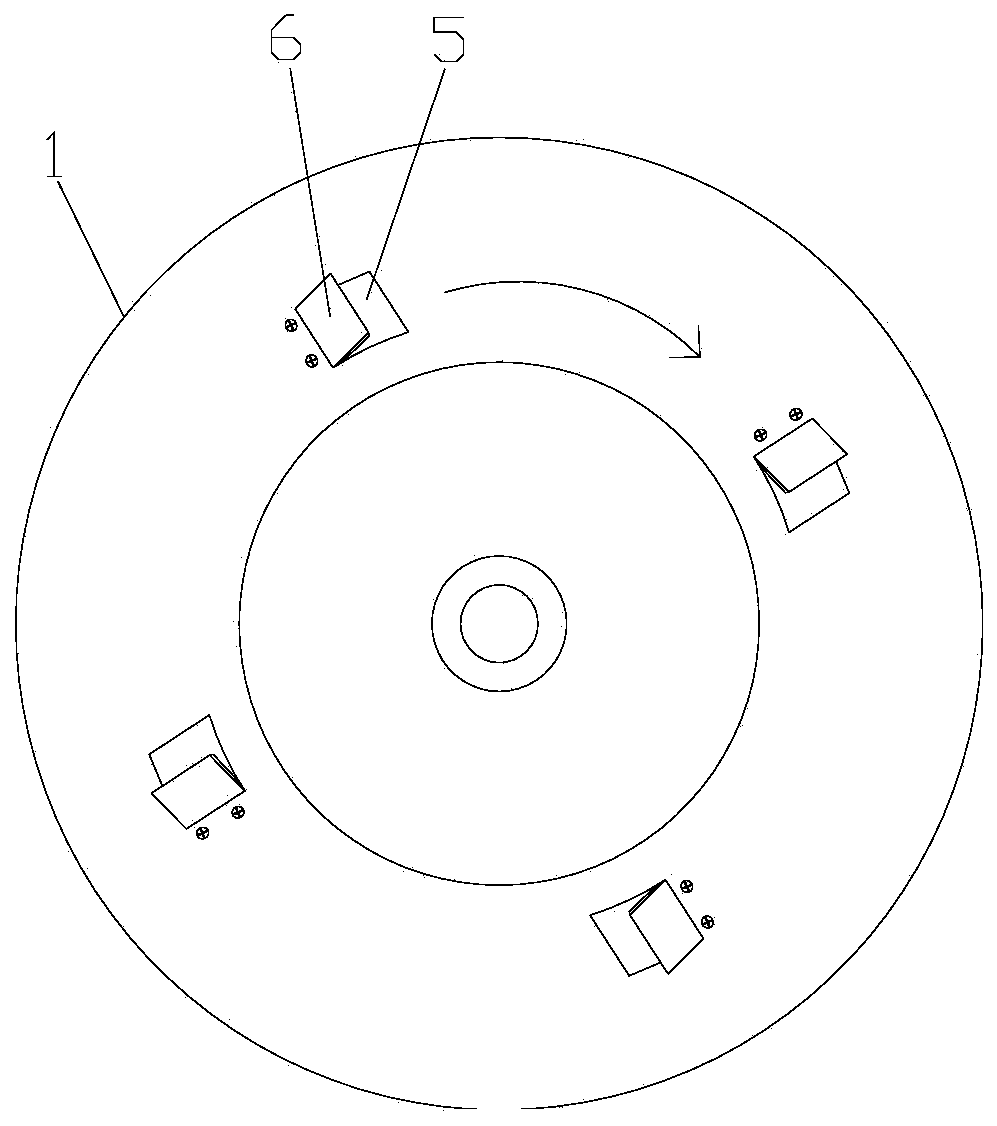

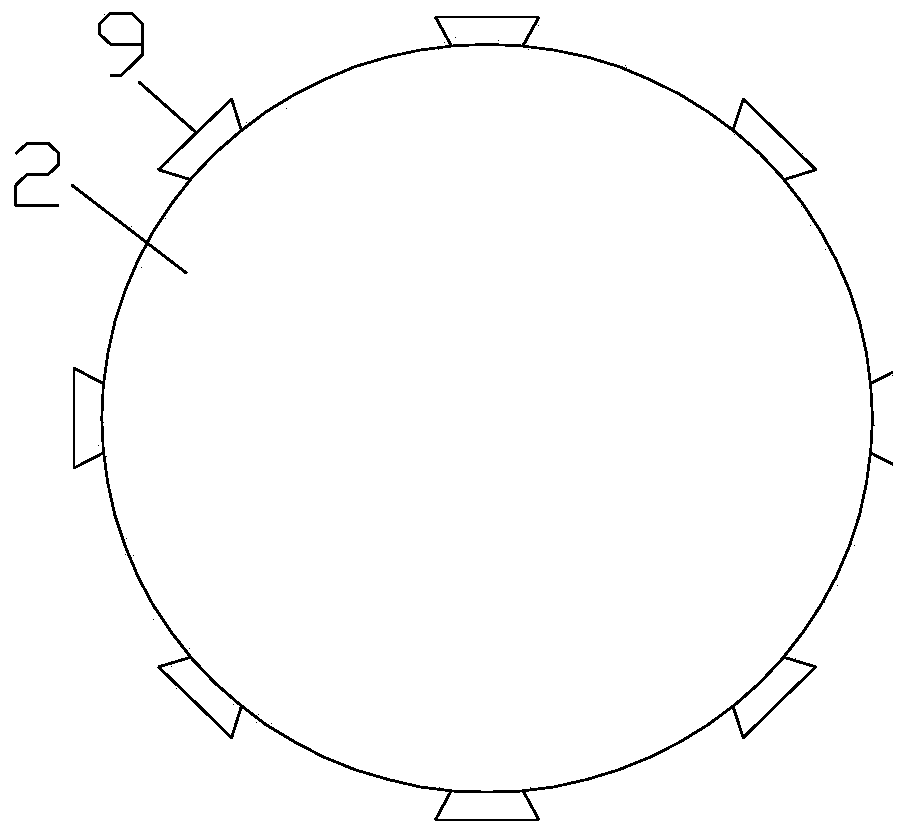

[0026] Such as Figure 1-4 As shown, a rotor of a motor includes an outer rotor housing 1 and a rotor shaft 2, the outer rotor housing 1 includes a cylindrical section 3 and a cone-shaped section 4, and the cylindrical section 3 and the cone-shaped section The section 4 is integrally arranged, and the middle part of the bottom of the cone-shaped section 4 is provided with a connecting hole (not shown) that matches the rotor shaft 2, and the end of the rotor shaft 2 is inserted into the connecting hole, and the rotor shaft 2 is suspended in the outer rotor casing 1 through the connection hole, and the air inlet 5 is arranged on the inclined surface of the cone-shaped section 4, and the air inlet 5 is inserted with a deflector 6, and the deflector 6 is in the form of The head end of the deflector 6 is located outside the cone-shaped section 4 and forms an air scraping inlet with the air inlet. The air scraping inlet is arranged at an acute angle. The opening direction of the air...

Embodiment 2

[0029] Such as Figure 1-4 As shown, a rotor of a motor includes an outer rotor housing 1 and a rotor shaft 2, the outer rotor housing 1 includes a cylindrical section 3 and a cone-shaped section 4, and the cylindrical section 3 and the cone-shaped section The section 4 is integrally arranged, and the middle part of the bottom of the cone-shaped section 4 is provided with a connecting hole (not shown) that matches the rotor shaft 2, and the end of the rotor shaft 2 is inserted into the connecting hole, and the rotor shaft 2 is suspended in the outer rotor casing 1 through the connection hole, and the air inlet 5 is arranged on the inclined surface of the cone-shaped section 4, and the air inlet 5 is inserted with a deflector 6, and the deflector 6 is in the form of The head end of the deflector 6 is located outside the cone-shaped section 4 and forms an air scraping inlet with the air inlet. The air scraping inlet is arranged at an acute angle. The opening direction of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com