Novel aqueous damping coating material for automotive interiors, preparation method and equipment thereof

A technology for damping coatings and automotive interiors, applied in the field of damping coatings, can solve the problems of easy cracking, easy to produce blisters, poor impact resistance, etc., and achieve the effect of solving bubbling, increasing strength, and filling gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

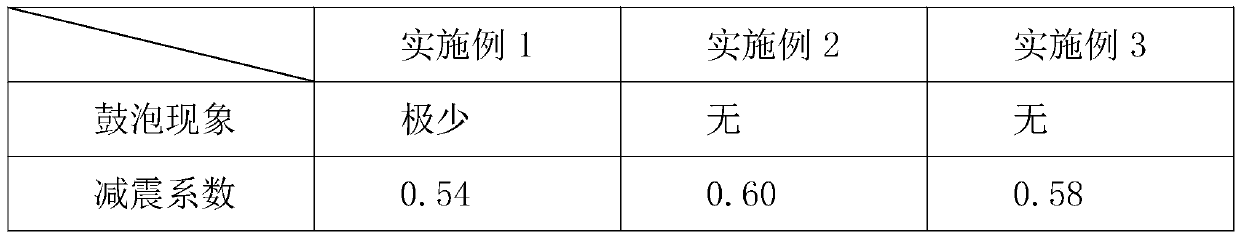

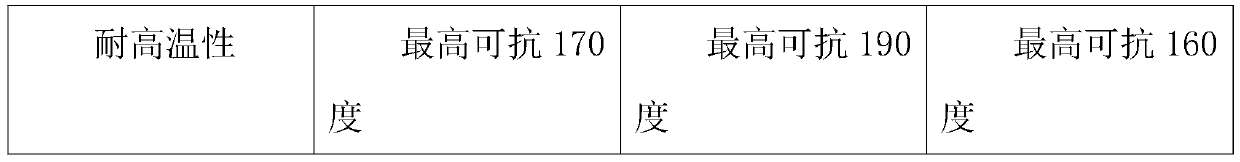

Examples

Embodiment 1

[0033]The novel water-based damping coating for automotive interior provided in this embodiment is made of the following components by weight: 10-20 parts of graphene slurry, 1-3 parts of defoamer, and 0.5-1.5 parts of thickener , 50-60 parts of modified glass powder, 3-5 parts of curing agent, 30-40 parts of environmentally friendly flame retardant, 60-80 parts of filler and 2-6 parts of film-forming aid.

[0034] Specifically, in this embodiment, it is made of the following components by weight: 10 parts of graphene slurry, 1 part of defoamer, 0.5 parts of thickener, 50 parts of modified glass powder, 3 parts of curing agent, environmental protection 30 parts of flame retardant, 60 parts of filler and 2 parts of film-forming aid.

[0035] Wherein, the defoamer is one or a combination of emulsified silicone oil and high-carbon alcohol fatty acid ester compound, and the thickener is homopolymer or copolymer emulsion of acrylic acid and methacrylic acid One or more combination...

Embodiment 2

[0042] The novel water-based damping paint, preparation method and equipment provided by the present embodiment are basically the same as in Example 1, except that:

[0043] The novel water-based damping coating for automotive interior provided in this embodiment is made of the following components by weight: 15 parts of graphene slurry, 2 parts of defoamer, 1 part of thickener, 55 parts of modified glass powder 4 parts, 4 parts of curing agent, 35 parts of environmentally friendly flame retardant, 70 parts of filler and 4 parts of film-forming aid.

[0044] The preparation method of the aforementioned novel water-based damping paint for interior decoration of automobiles specifically comprises the following steps:

[0045] S1. Preparation of raw materials: Weigh the raw materials in appropriate proportions with measuring tools in advance, and store them separately for later use. Add 55 parts of modified glass powder and 35 parts of environmentally friendly flame retardants to...

Embodiment 3

[0049] The novel water-based damping paint, preparation method and equipment provided by the present embodiment are basically the same as those in Examples 1 and 2, except that:

[0050] The novel water-based damping paint for interior decoration of a kind of automobile provided by the present embodiment is made of the following components by weight: 20 parts of graphene slurry, 3 parts of defoamer, 1.5 parts of thickener, 60 parts of modified glass powder 5 parts, 5 parts of curing agent, 40 parts of environmentally friendly flame retardant, 80 parts of filler and 6 parts of film-forming aid.

[0051] The preparation method of the aforementioned novel water-based damping paint for interior decoration of automobiles specifically comprises the following steps:

[0052] S1. Preparation of raw materials: Weigh the appropriate proportion of raw materials with measuring tools in advance, and store them separately for later use. Add 60 parts of modified glass powder and 40 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com