Environment-friendly self-extinction waterborne polyurethane and preparation method and application thereof

A water-based polyurethane, self-extinguishing technology, applied in polyurea/polyurethane coatings, applications, animal husbandry, etc., can solve the problems of poor basic performance of coatings, cumbersome and time-consuming synthesis steps, difficult industrial production, etc. Simple and convenient production process, natural surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

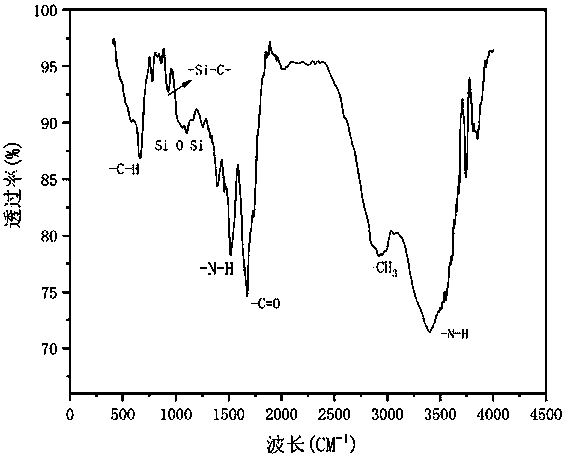

[0045](1) Add 16.667g of polytetrahydrofuran ether glycol 1000 (PTMG1000), 0.226g of silok 8861 and 0.452g of trimethylolpropane (TMP) into the reactor respectively, and remove water under vacuum at 120°C for 2 hours , Dissolved in 7g of acetone. Lower the temperature to 60°C, add 10.545g of isophorone diisocyanate (IPDI), stir evenly, raise the temperature to 85°C, then add the catalyst dibutyltin dilaurate (DBTDL) (based on the mass of prepolymer 0.16 wt%), the reactant was reacted at 85°C for 3h to obtain 34.89g of prepolymer.

[0046] (2) Add 0.813 g of 2,2-dimethylolpropionic acid (DMPA) to the above prepolymer, and continue to react at 85° C. for 2 hours. Then start to lower the temperature, cool the prepolymer to 40°C and neutralize the reaction with 0.614g of triethylamine (TEA) (the molar ratio of DMPA is 1:1) for 30 minutes.

[0047] (3) Disperse the obtained prepolymer in deionized water containing 0.151g of 2-[(2-aminoethyl)amino]ethanesulfonic acid sodium salt (...

Embodiment 2

[0051] (1) Add 25g of polypropylene glycol 1000 (PPG1000), 0.225g of silok 8861 and 0.675g of trimethylolpropane (TMP) into the reaction kettle, remove water under vacuum at 120°C for 2 hours, dissolve in 10g of acetone. Lower the temperature to 60°C, add 15.771g of isophorone diisocyanate (IPDI), stir evenly, raise the temperature to 85°C, then add the catalyst dibutyltin dilaurate (DBTDL) (based on the mass of prepolymer 0.16 wt%), the reactant was reacted at 85°C for 3h to obtain 51.671g of prepolymer.

[0052] (2) Add 1.215 g of 2,2-dimethylolbutyric acid (DMBA) to the above prepolymer, and continue to react at 85° C. for 2 hours. Then start to lower the temperature, cool the prepolymer to 40°C and neutralize the reaction with 0.918g of tripropylamine (the molar ratio to DMBA is 1:1) for 30 minutes.

[0053] (3) Disperse the obtained prepolymer in deionized water containing 0.225 g of 2-[(2-aminoethyl)amino]propanesulfonic acid sodium salt at room temperature with a stir...

Embodiment 3

[0056] (1) Add 33.333g of polycaprolactone diol 1000 (PCL1000), 0.611g of silok 8861 and 0.907g of trimethylolpropane (TMP) into the reactor respectively, and remove water under vacuum at 120°C for 2 Hours, dissolved in 13g of acetone. Lower the temperature to 60°C, add 21.144g of isophorone diisocyanate (IPDI), stir evenly, raise the temperature to 85°C, then add the catalyst dibutyltin dilaurate (DBTDL) (based on the mass of prepolymer 0.16 wt%), the reactant was reacted at 85°C for 3h, and 68.995g of prepolymer was obtained.

[0057] (2) 1.633 g of 2,2-dimethylolbutyric acid (DMBA) was added to the above prepolymer, and the reaction was continued at 85° C. for 2 hours. Then start to lower the temperature, cool the prepolymer to 40°C and neutralize the reaction with 1.233g of triethylamine (TEA) (the molar ratio of DMBA is 1:1) for 30 minutes.

[0058] (3) Disperse the obtained prepolymer in deionized water containing 0.303g of 2-[(2-aminoethyl)amino]ethanesulfonic acid so...

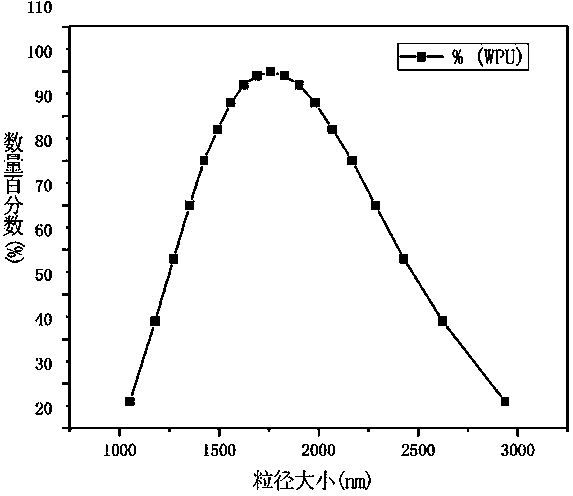

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com