Novel anti-leakage and steam-recycling copper processing equipment

A processing equipment and steam technology, applied in the detailed information of chemical/physical/physical chemical reactors, metal material coating technology, liquid chemical plating, etc., can solve the problems of steam waste heat waste, harmful gas leakage, etc., and achieve accelerated Feeding time, enhanced leakage prevention performance, and the effect of realizing environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

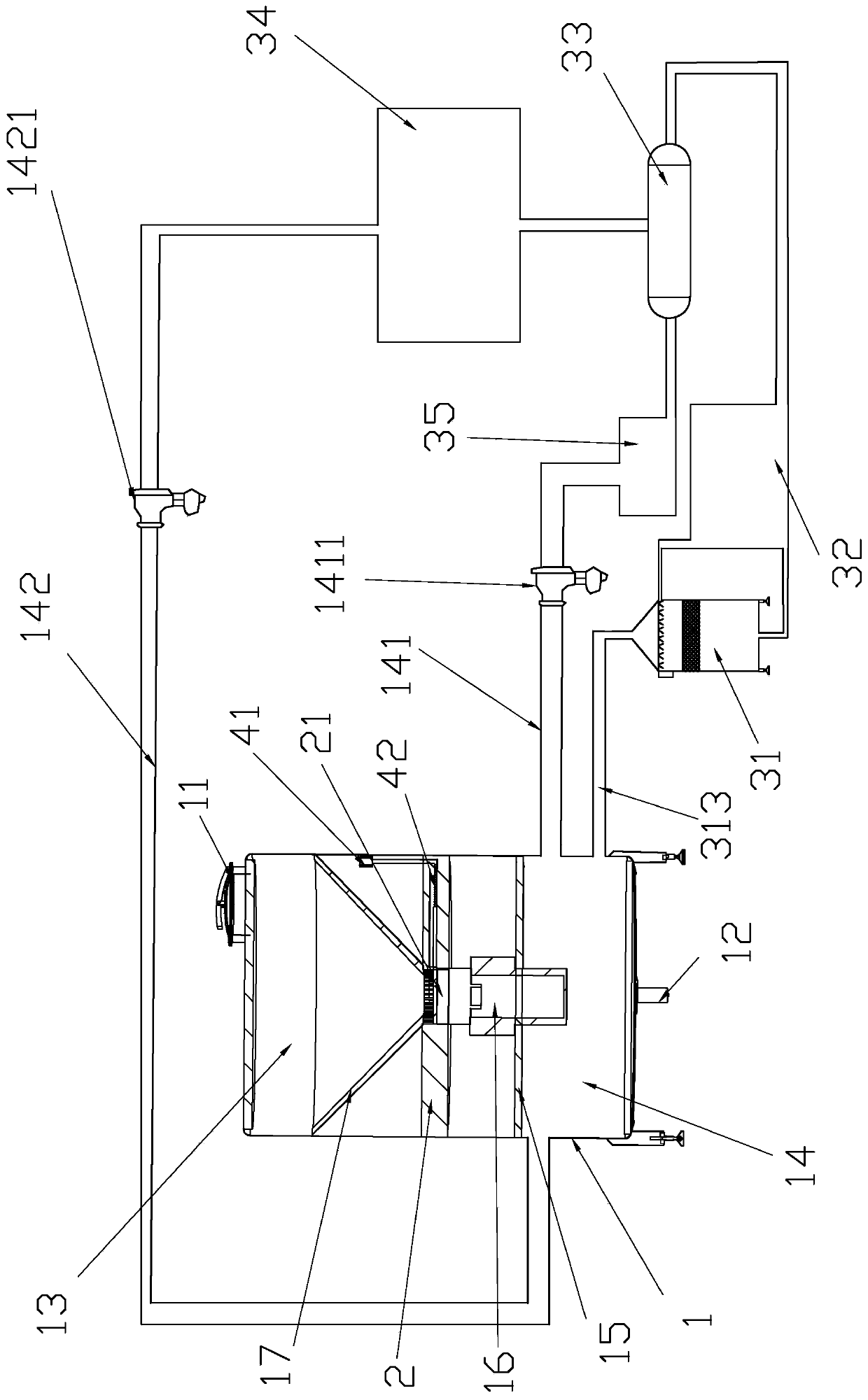

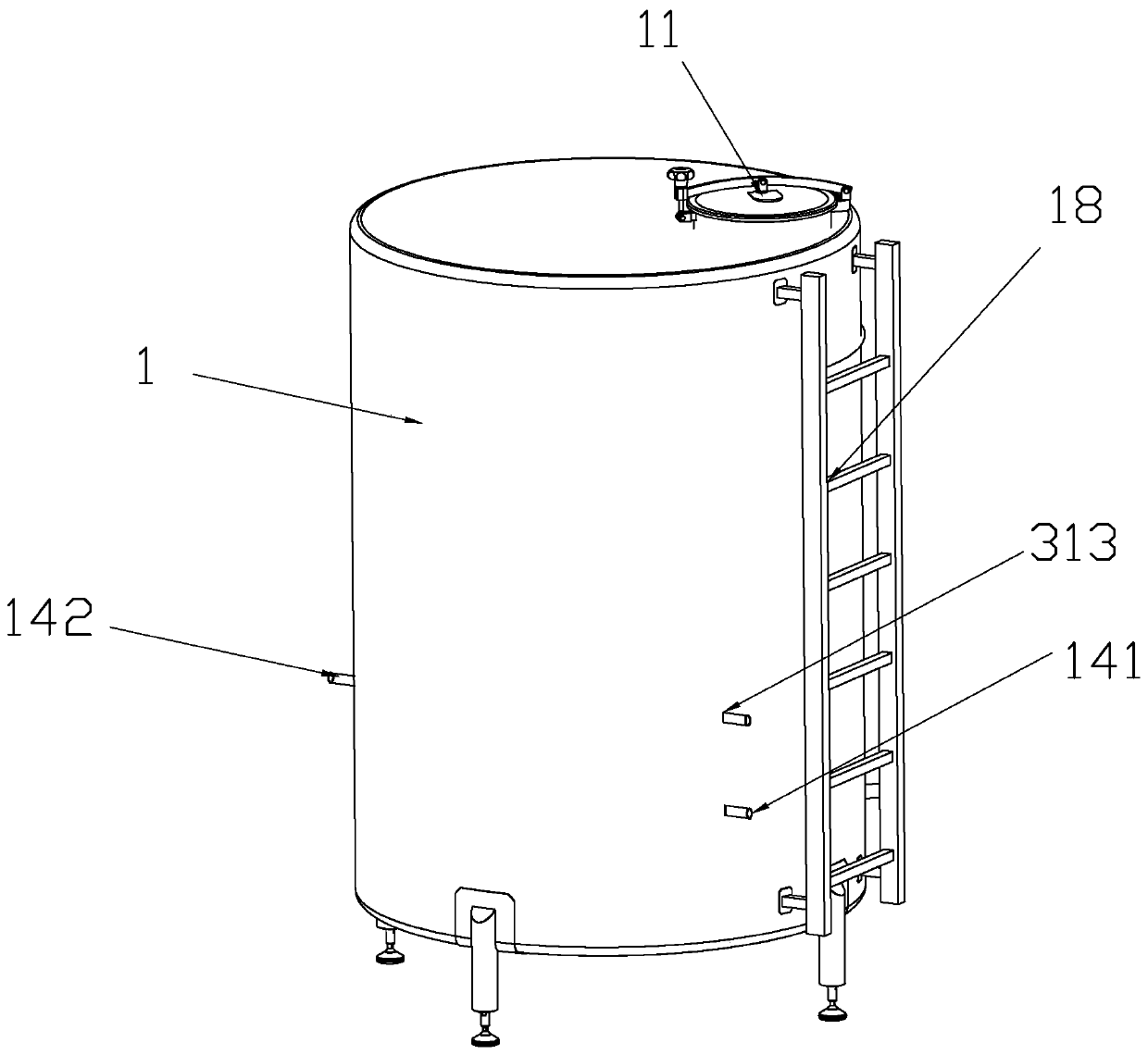

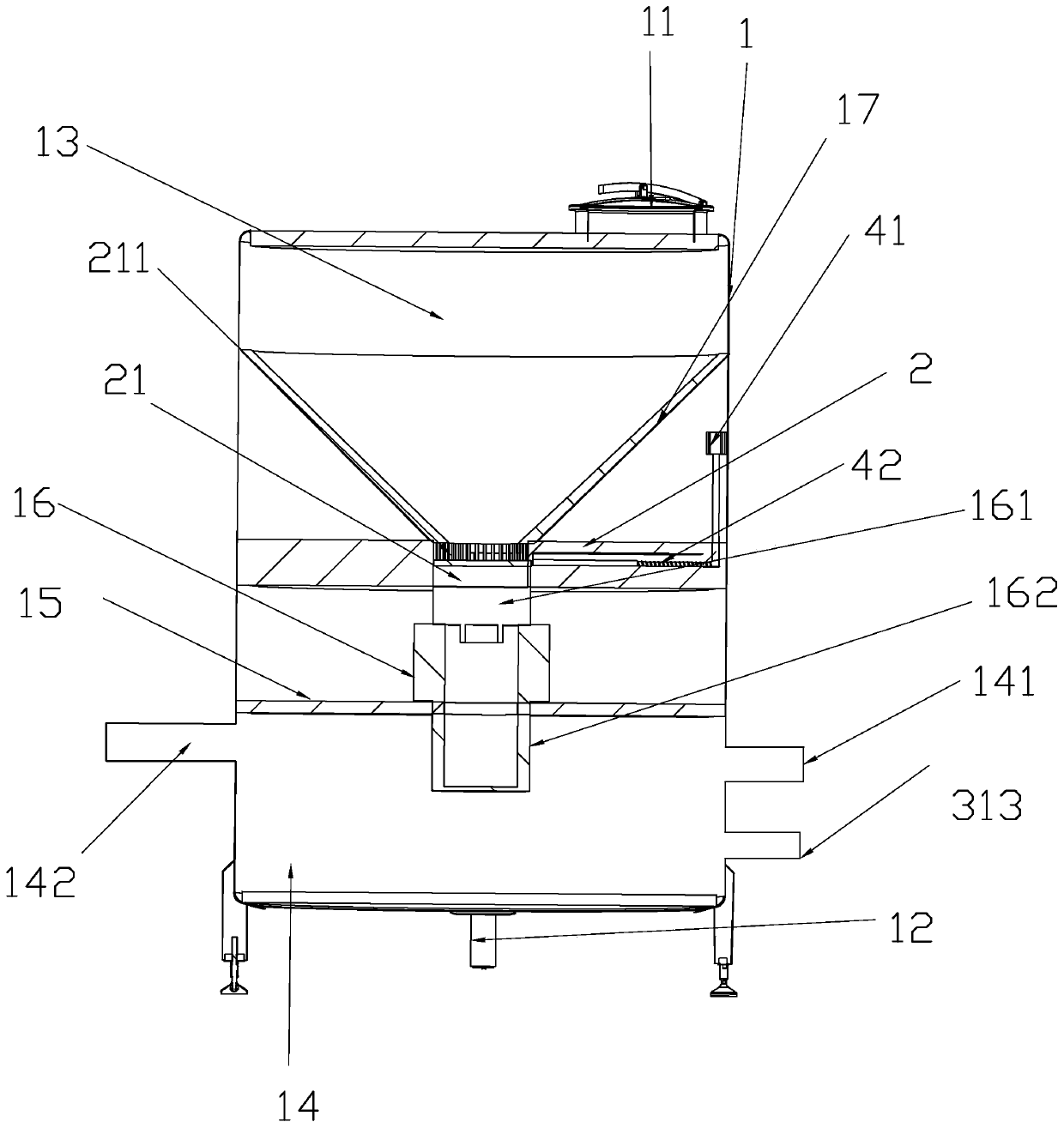

[0033] like Figure 1-Figure 6 As shown, a new type of copper processing equipment for anti-leakage steam circulation, including a reactor 1, the top of the reactor 1 is provided with a feed valve 11, the bottom is provided with a discharge valve 12, and the reactor 1 is provided with a reactor 1 The partition plate 2 fixedly connected to the inner wall, the partition plate 2 divides the interior of the reactor 1 into a feeding chamber 13 and a reaction chamber 14, the end of the reactor 1 near the feeding valve 11 is the feeding chamber 13, and the end near the discharge valve 12 is the reaction chamber 14. The center of the partition plate 2 is provided with a material guide hole 21 connecting the feeding chamber 13 and the reaction chamber 14. The partition plate 2 is provided with an anti-leakage material separation mechanism for controlling whether the material guide hole 21 is conducted. One end of 14 is provided with the vapor circulation device that the steam in reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com