A method of removing solid particles from oil slurry by heat treatment centrifugal sedimentation-electrostatic method

A centrifugal sedimentation and removal technology, which is applied in the treatment of hydrocarbon oil, multi-stage series refining process treatment, and petroleum industry, etc. It can solve the problem of difficult to adapt to the complex nature of catalytic oil slurry, and achieve high desolidification efficiency and economical improvement. Value, effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1. A refinery catalytic cracking oil slurry A is selected to carry out the desolidification research of the present invention, and the basic properties of the oil slurry X are shown in Table 1.

[0022] Table 1 Raw material oil slurry X property table

[0023]

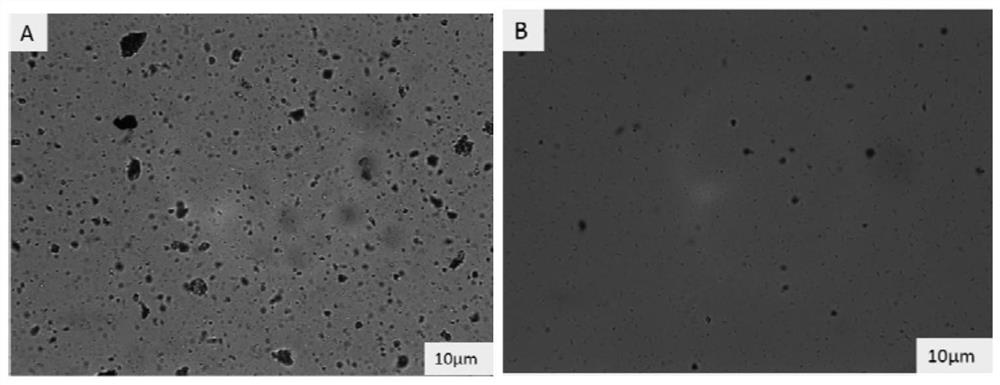

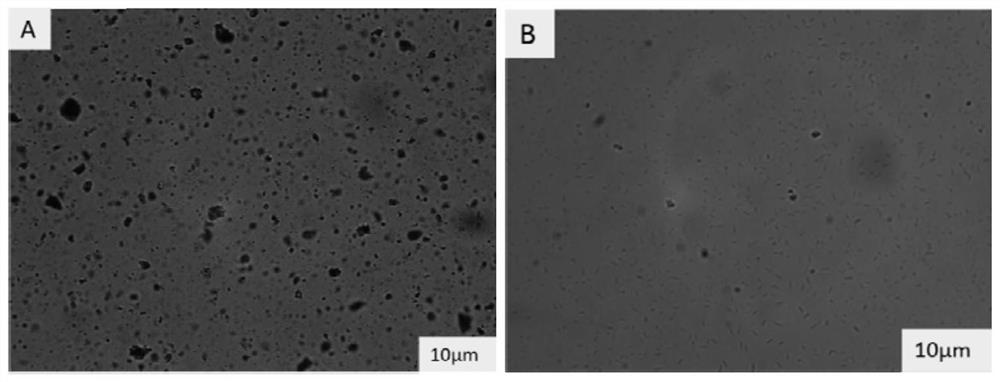

[0024] (1) Pour 1 MPa of nitrogen into the centrifugal settling tank. The temperature of the centrifugal settling tank is maintained at about 350°C and the centrifugal force is 1000×g. The oil slurry X is heat-treated and centrifugally settled in the centrifugal settling tank for about 10 hours.

[0025] (2) Pump 90% of the oil slurry in the upper layer obtained after heat treatment and centrifugal sedimentation into an electrostatic tower for electrostatic treatment. The electrostatic separation temperature is 160°C, the processing voltage is 15kV DC high voltage, and the processing time is 25 minutes.

[0026] The property change of oil slurry X after being treated by the method of the present i...

Embodiment 2

[0039] Example 2. The desolidification research of the present invention was carried out by using catalytic cracking oil slurry Y from different refineries. The basic properties of the oil slurry Y are shown in Table 4.

[0040] Table 4 Raw material oil slurry Y property table

[0041]

[0042]

[0043] (1) Pour 1MPa nitrogen into the centrifugal settling tank, maintain the temperature of the centrifugal settling tank at about 350°C, and the centrifugal force at 1000×g, heat-treat the oil slurry Y in the centrifugal settling tank for about 10 hours.

[0044] (2) Pump 90% of the oil slurry in the upper layer obtained after heat treatment and centrifugal sedimentation into an electrostatic tower for electrostatic treatment. The electrostatic separation temperature is 160°C, the processing voltage is 15kV DC high voltage, and the processing time is 25 minutes.

[0045] The property change of oil slurry Y after being treated by the method of the present invention is shown i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com