Composite, raw material composition, bone repair body, preparation method and application

A raw material composition and composite material technology, applied in the field of medical biomaterials, can solve the problems of poor osteogenic performance, mismatched mechanical properties, bone resorption, etc., and achieve the effects of improved osteogenic activity and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] The preparation method of PT25 material: 8.10kg of tantalum powder with a volume fraction of 25% and a particle size of 1-3 μm and 1.90 kg of polyether ketone ketone powder with a volume fraction of 75% and a particle size of 30-40 μm are mixed at high speed Machine mixing to obtain mixed powder; then use twin-screw extruder to extrude the mixed powder to granulate, the extrusion temperature of the extruder is 370 ° C ~ 380 ° C; the extrusion pressure is 80 MPa ~ 100 MPa; the particle size of the extrusion masterbatch is 2-5mm; then use the injection molding machine to inject the masterbatch to obtain the product, the injection temperature is 370-380°C; the pressure of the injection molding machine is 80-120MPa.

[0128] The preparation method of PT50 material: Mix 18.56kg of tantalum powder with a volume fraction of 50% and a particle size of 1-3 μm and 1.44 kg of PEKK powder with a volume fraction of 50% and a particle size of 30-40 μm with a high-speed mixer. Obtain ...

Embodiment 2

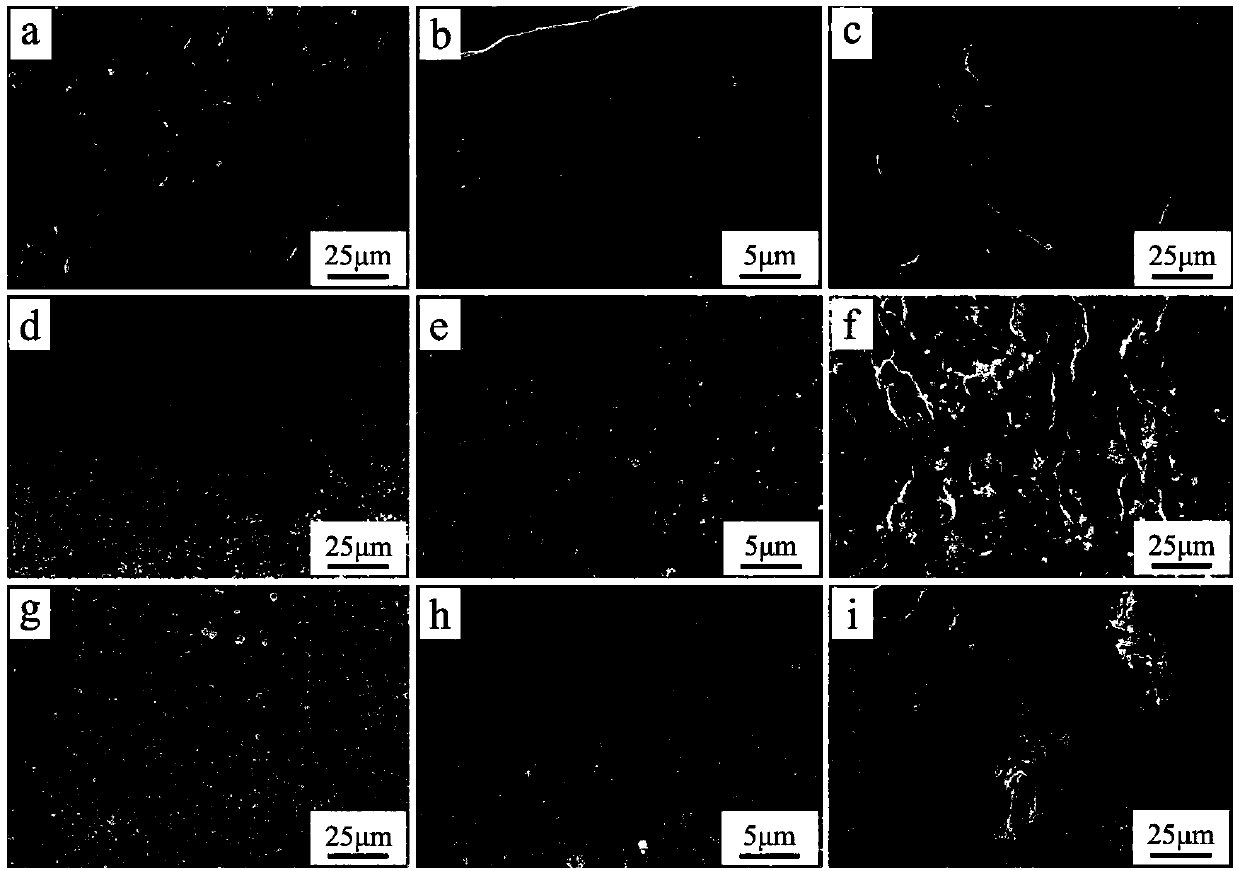

[0130] The preparation method of PT25 material: 8.10kg of tantalum powder with a volume fraction of 25% and a particle size of 1-3 μm and 1.90 kg of polyether ketone ketone powder with a volume fraction of 75% and a particle size of 30-40 μm are mixed at high speed Machine mixing to obtain mixed powder; then use a twin-screw extruder to extrude the mixed powder to obtain the product. The extrusion temperature of the extruder is 370°C to 380°C; the extrusion pressure is 80MPa to 100MPa. The SEM photos of the surface and cross-sectional morphology of the prepared PT25 material are shown in figure 1 Figures d, e, and f in Fig.

[0131] The preparation method of PT50 material: Mix 18.56kg of tantalum powder with a volume fraction of 50% and a particle size of 1 to 3 μm and 1.44 kg of polyether ketone ketone powder with a volume fraction of 50% and a particle size of 30 to 40 μm at high speed Machine mixing, mixed powder; all the other steps are the same as the preparation method ...

Embodiment 3

[0136] Preparation method of PT50 bone prosthesis: 18.56 kg of tantalum powder with a volume fraction of 50% and a particle size of 1-3 μm and 1.44 kg of polyetherketone-ketone powder with a volume fraction of 50% and a particle size of 30-40 μm are used A high-speed mixer mixes to obtain a mixed powder; all the other steps are the same as in Example 1 (using the mold of the artificial joint). The mechanical properties of the obtained PT50 bone restorations are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com