Preparation and application of PEO-based film coated silicon carbon electrode

A technology of coating silicon and thin films, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problem of Si nano particle crushing, achieve the effect of reducing the falling off of crushed particles and good electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Weigh silicon carbon negative electrode material silicon carbon 650, aqueous binder sodium hydroxymethyl cellulose (CMC), styrene-butadiene rubber (SBR), and conductive agent (superP), according to the mass ratio of 8:0.5:0.5; 1 Mix and grind evenly, add an appropriate amount of ultrapure water and place on a magnetic stirrer to fully stir for 8 hours. Coated, and then placed in a vacuum oven to dry at 80°C for later use.

[0026] (2) Dissolve PEO in acetonitrile solution, fully mix and dissolve, and then add lithium bistrifluoromethanesulfonimide to prepare a mixed solution with a mass fraction of PEO of 1%, wherein the molar ratio of PEO to lithium salt is 1:15 .

[0027] (3) Fix the dried silicon carbon electrode sheet on the glass plate, select a 500mm scraper, scrape and coat the PEO mixed solution on the electrode sheet, and dry it in the glove box to volatilize the acetonitrile solvent to obtain a PEO-based film coating Silicon carbon electrodes.

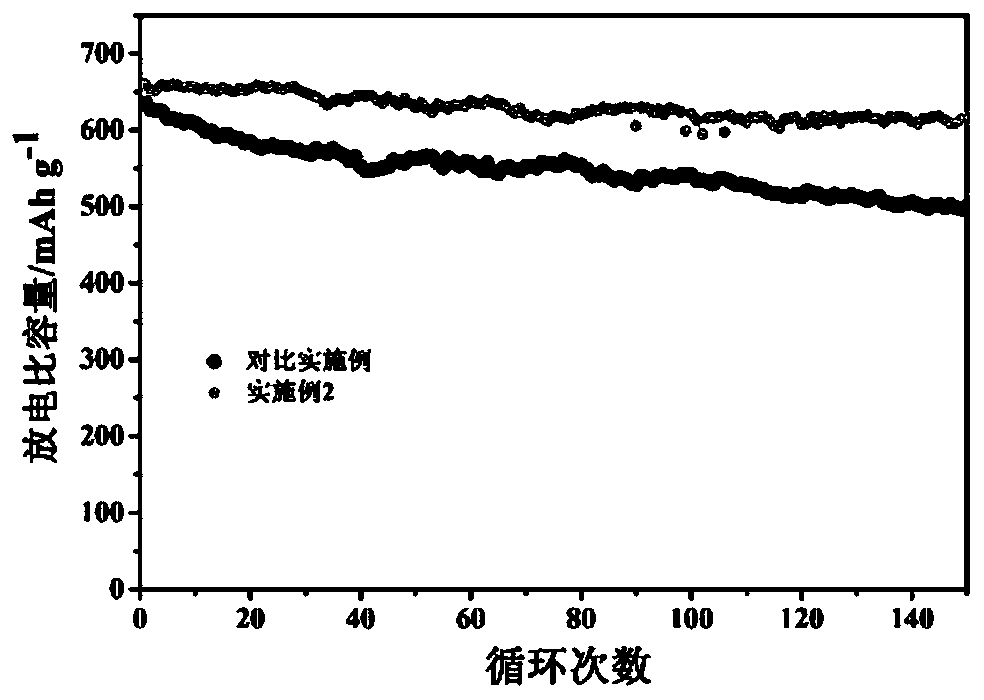

Embodiment 2

[0029] (1) Weigh silicon carbon negative electrode material silicon carbon 650, aqueous binder sodium hydroxymethyl cellulose (CMC), styrene-butadiene rubber (SBR), and conductive agent (superP), according to the mass ratio of 8:0.5:0.5; 1 Mix and grind evenly, add an appropriate amount of ultrapure water and place on a magnetic stirrer to fully stir for 8 hours. Coated, and then placed in a vacuum oven to dry at 80°C for later use.

[0030] (2) Dissolve PEO in acetonitrile solution, fully mix and dissolve, and then add lithium bistrifluoromethanesulfonimide to prepare a mixed solution with a mass fraction of PEO of 3%, wherein the molar ratio of PEO to lithium salt is 1:15 .

[0031] (3) Fix the dried silicon carbon electrode sheet on the glass plate, select a 500mm scraper, scrape and coat the PEO mixed solution on the electrode sheet, and dry it in the glove box to volatilize the acetonitrile solvent to obtain a PEO-based film coating Silicon carbon electrodes.

Embodiment 3

[0033] (1) Weigh silicon carbon negative electrode material silicon carbon 650, aqueous binder sodium hydroxymethyl cellulose (CMC), styrene-butadiene rubber (SBR), and conductive agent (superP), according to the mass ratio of 8:0.5:0.5; 1 Mix and grind evenly, add an appropriate amount of ultrapure water and place on a magnetic stirrer to fully stir for 8 hours. Coated, and then placed in a vacuum oven to dry at 80°C for later use.

[0034] (2) Dissolve PEO in acetonitrile solution, fully mix and dissolve, and then add lithium bistrifluoromethanesulfonimide to prepare a mixed solution with a mass fraction of PEO of 5%, wherein the molar ratio of PEO to lithium salt is 1:15 .

[0035] (3) Fix the dried silicon carbon electrode sheet on the glass plate, select a 500mm scraper, scrape and coat the PEO mixed solution on the electrode sheet, and dry it in the glove box to volatilize the acetonitrile solvent to obtain a PEO-based film coating Silicon carbon electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com