Nonaqueous electrolyte additive and nonaqueous electrolyte containing the additive

A non-aqueous electrolyte and additive technology, which is applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems of being unable to prevent the high-temperature and high-pressure reaction between the electrode and the electrolyte, and the film is fragile, achieving high strength, protecting the electrode, The effect of high ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

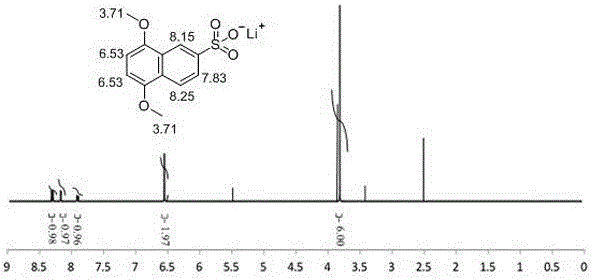

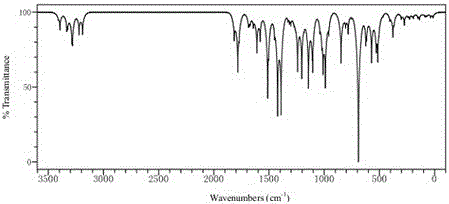

Embodiment 1

[0087] 81 g of ethyl methyl carbonate, 14.5 g of lithium perchlorate and 4.5 g of lithium 1,4-dimethoxynaphthalene-7-sulfonate were uniformly mixed to obtain electrolytic solution 1.

[0088] In the argon glove box, assemble the positive electrode sheet, negative electrode sheet and separator commonly used in lithium-ion secondary batteries in the battery case, and separate the positive electrode sheet and the negative electrode sheet with the separator, assemble it into a button battery, and inject electrolyte 1, Lithium-ion battery 1 is made after sealing.

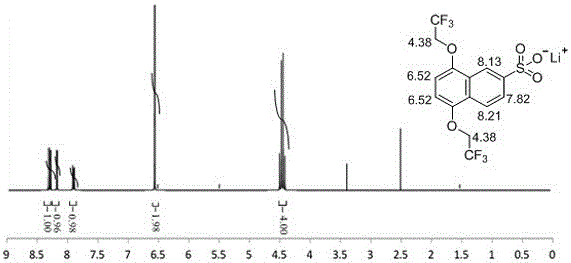

Embodiment 2

[0090] 40g of dimethyl carbonate and 51g of methyl acetate, 8.9g of lithium hexafluorophosphate and 0.1g of 1,4-two-2,2,2-trifluoroethoxynaphthalene-7-lithium sulfonate were mixed uniformly to obtain Electrolyte 2.

[0091] In the argon glove box, assemble the positive electrode sheet, negative electrode sheet and separator commonly used in lithium-ion secondary batteries in the battery case, and separate the positive electrode sheet and the negative electrode sheet with the separator, assemble it into a button battery, and inject electrolyte 2, Lithium-ion battery 2 is made after sealing.

Embodiment 3

[0093] Mix 50g of diethyl carbonate and 40.5g of ethylene carbonate, 2g of lithium tetrafluoroborate, 2.5g of bisoxalate lithium borate and 5g of 9,10-dimethoxyanthracene-2-sulfonate lithium, Electrolyte 3 is obtained.

[0094] In the argon glove box, assemble the positive electrode sheet, negative electrode sheet and separator commonly used in lithium-ion secondary batteries in the battery case, and separate the positive electrode sheet and the negative electrode sheet with the separator, assemble it into a button battery, and inject the electrolyte 3, Lithium-ion battery 3 is made after sealing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com