Construction method of water-rich and weak surrounding rock tunnel crossing fault fracture zone

A technology for weak surrounding rock and tunnel construction, used in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of unguaranteed safety and quality, distortion of subsidence arches, and restricted construction period, etc., and is conducive to the safety of tunnel construction. , Support stability performance guarantee, the effect of resisting the external force of the tunnel shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

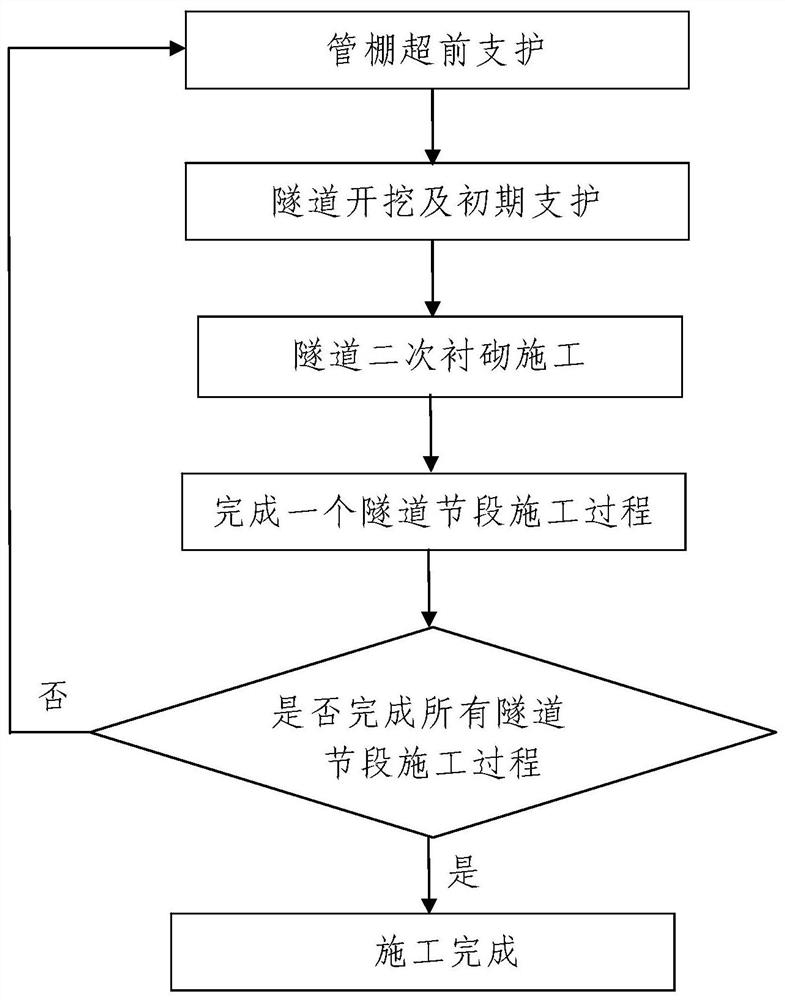

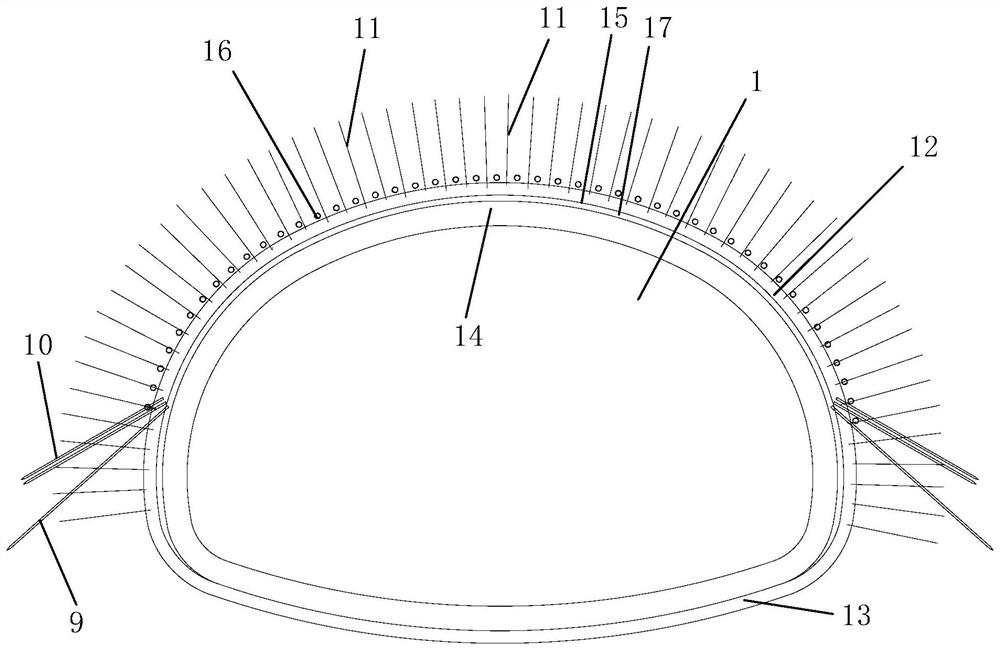

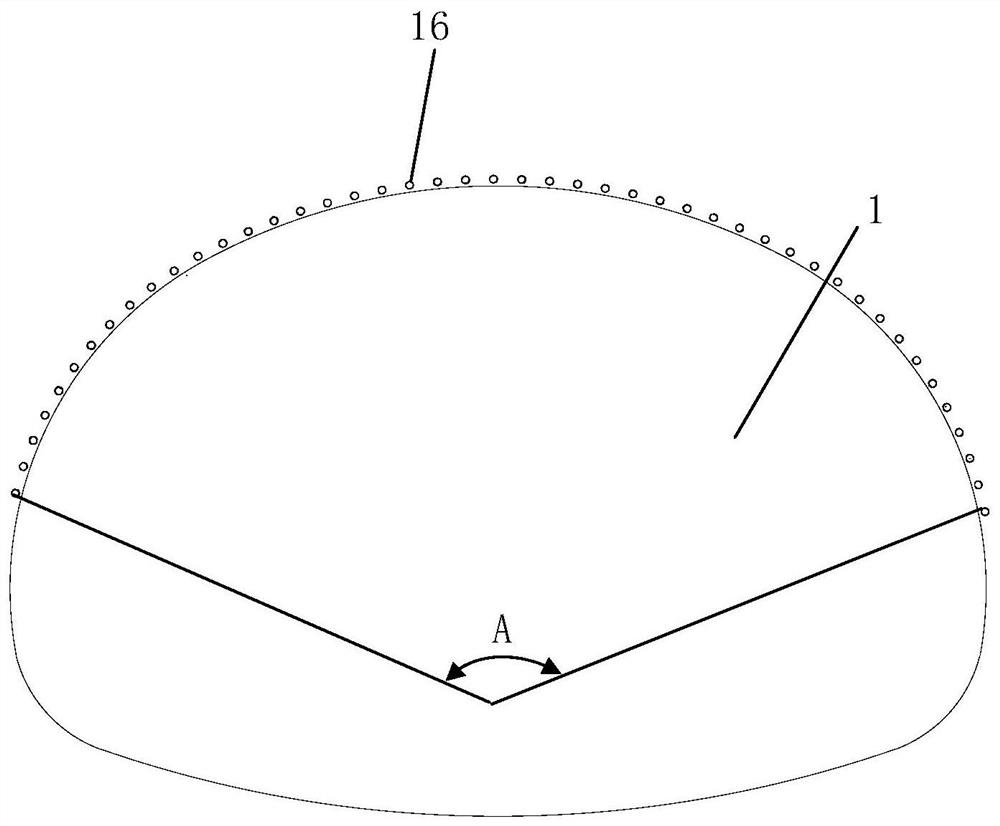

[0109] Such as figure 1 Shown is a construction method for tunnels with rich water and weak surrounding rocks passing through the fractured fault zone. The primary support structure of the tunnel for primary support and the tunnel secondary lining 14 arranged inside the primary support structure of the tunnel, the primary support structure of the tunnel and the secondary lining 14 of the tunnel are both tunnels for the constructed tunnel 1 A full-section support structure in which the tunnel is fully supported, and the secondary lining 14 of the tunnel is a reinforced concrete lining; the cross-sectional area of the tunnel hole is greater than 100m 2 , see figure 2 , image 3 ; combine Figure 15 , the tunnel hole is divided into an upper hole body 1-5 and a lower hole body 1-6 located directly below the upper hole body 1-5; the excavation height of the tunnel hole is greater than 10m, and the opening of the upper hole body 1 The excavation height is 6.5m-8m, and the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com