Grinding liquid cleaning agent and preparation method thereof

A polishing liquid and cleaning agent technology, applied in the field of metal surface cleaning agent and polishing liquid cleaning agent for 6 series aluminum alloys, can solve problems such as easy corrosion, and achieve the effects of good dispersion, improved cleaning performance, and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

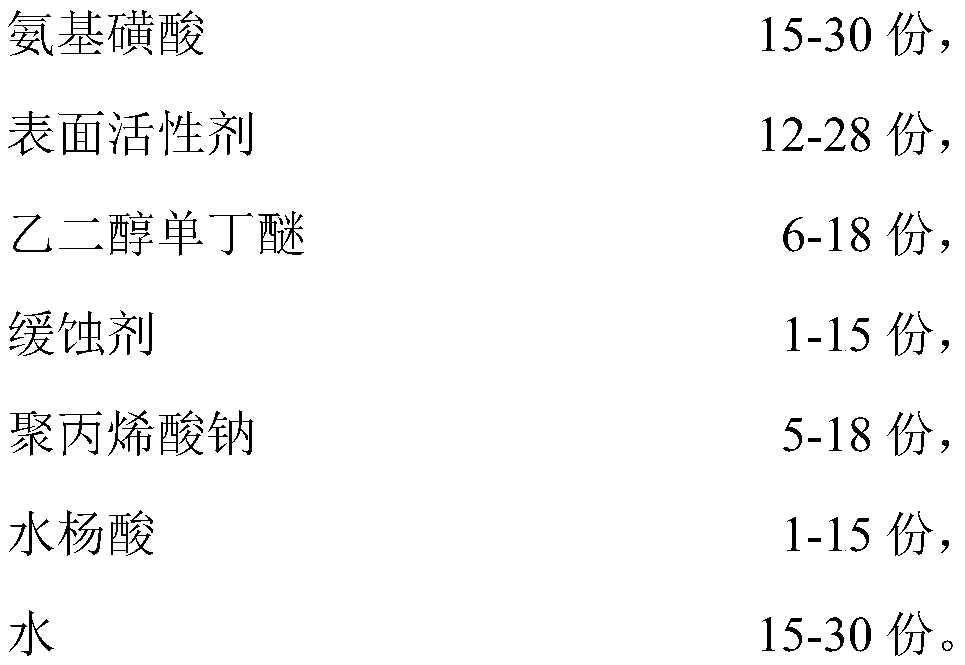

[0036] The present embodiment grinding fluid cleaning agent is made up of the component of following weight:

[0037]

[0038] The siloxane ketone is NEUF815 siloxane ketone.

[0039] The preparation method of the grinding liquid cleaning agent of the present embodiment comprises the following steps:

[0040] (1) Add deionized water, sulfamic acid, salicylic acid and silicone ketone into the reaction kettle in sequence according to weight, stir at 25°C for 20min at a stirring speed of 75rpm, then slowly add sodium polyacrylate and stir for 20min, Cool to room temperature to obtain mixed solution 1;

[0041] (2) Add organic amine ester TPP and ethylene glycol monobutyl ether to the above mixed solution 1, and stir for 25 minutes at a stirring speed of 75 rpm to obtain a grinding liquid cleaning agent.

[0042] Cleaning effect test:

[0043] Test method: refer to the cleaning power test method in GB / T 35759-2017 metal cleaning agent, but replace the artificial oil in the s...

Embodiment 2

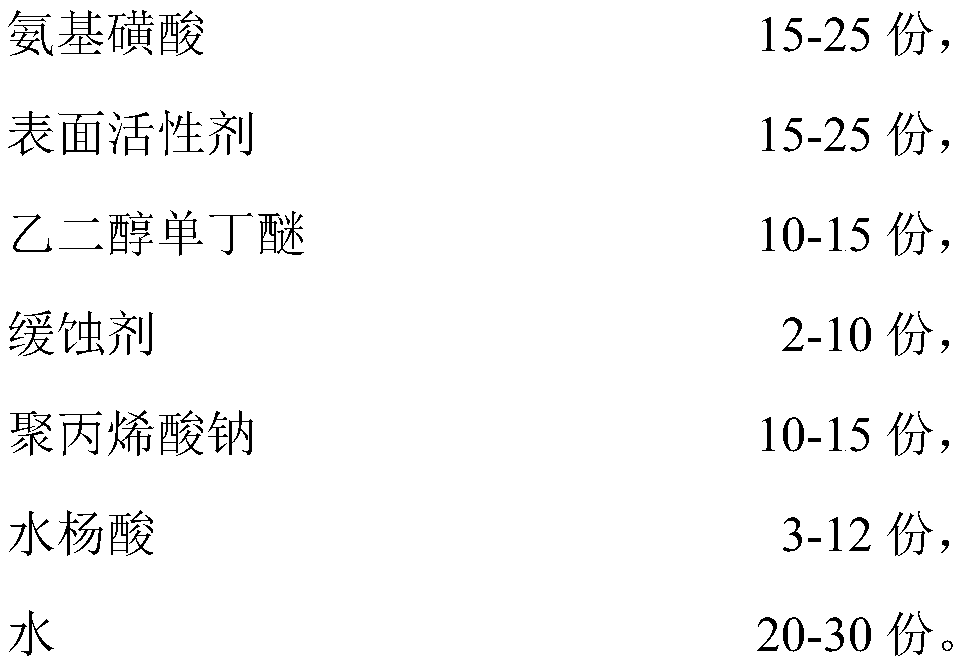

[0045] The present embodiment grinding liquid cleaning agent is made up of the component of following weight:

[0046]

[0047] The siloxane ketone is NEUF815 siloxane ketone.

[0048] The preparation method of the grinding liquid cleaning agent of this embodiment is the same as that of Embodiment 1.

[0049] The cleaning effect test method of this embodiment is the same as that of Example 1, and its test results are as shown in Table 1.

Embodiment 3

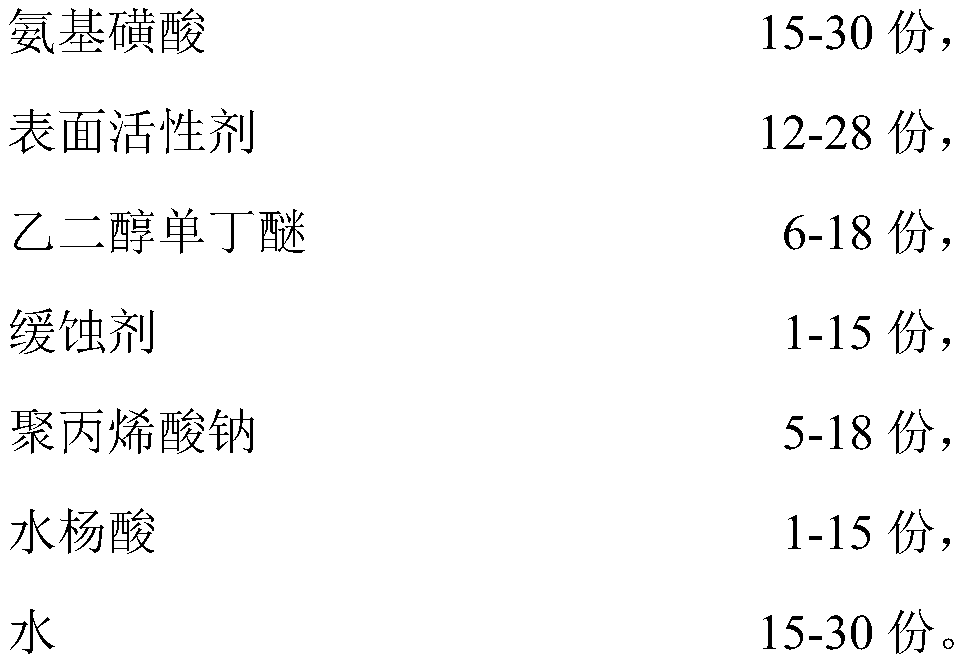

[0051] The present embodiment grinding liquid cleaning agent is made up of the component of following weight:

[0052]

[0053] The siloxane ketone is NEUF815 siloxane ketone.

[0054]The preparation method of the grinding liquid cleaning agent of this embodiment is the same as that of Embodiment 1.

[0055] The cleaning effect test method of this embodiment is the same as that of Example 1, and its test results are as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com