Cement-based capillary crystalline waterproof coating and preparation method thereof

A technology of infiltration crystallization and waterproof coating, applied in the field of building waterproof materials, can solve the problems of impermeability and waterproof performance, bonding performance and poor flexural and compressive strength, so as to improve the impermeability and waterproof effect, improve the impermeability and improve the The effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

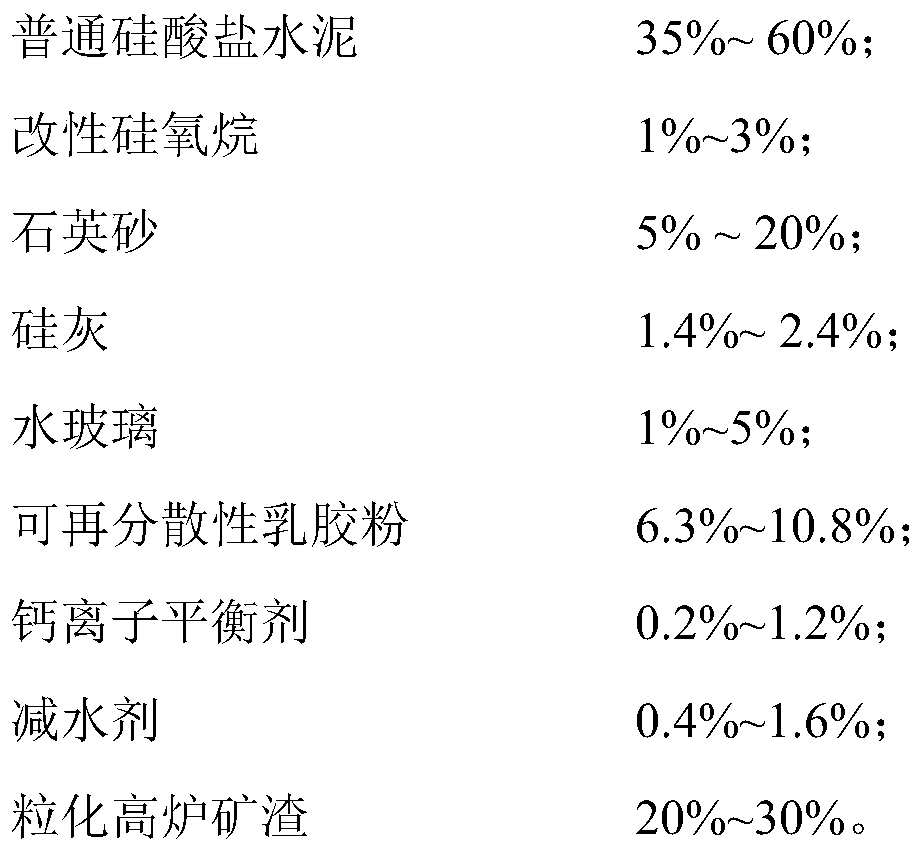

Method used

Image

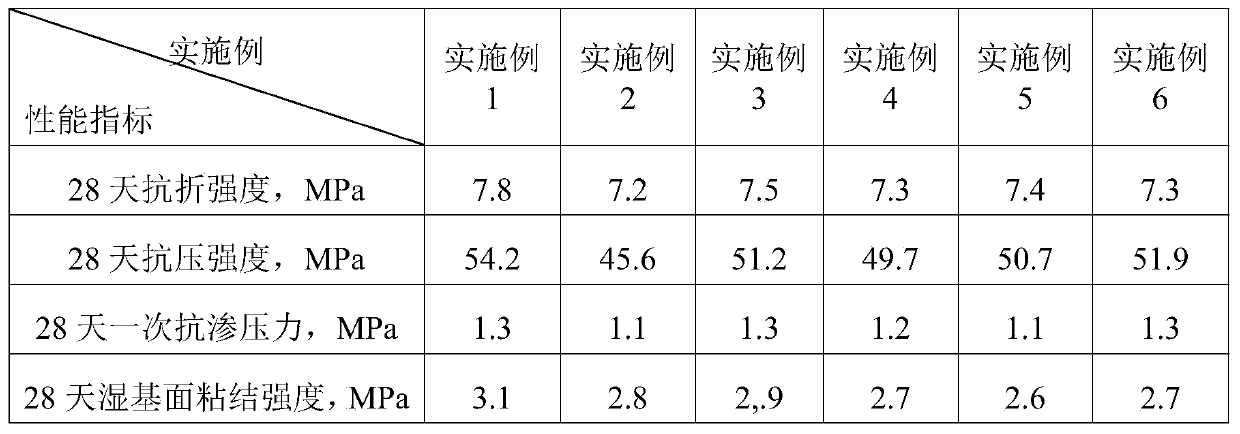

Examples

preparation example Construction

[0030] The preparation method of the above-mentioned osmotic crystalline waterproof coating mainly includes: using a planetary mortar mixer, wiping the mixing blade and the mixing bucket with a clean damp cloth before mixing, first mixing the modified siloxane, calcium ion balancer, Add water reducer and water into the mixing tank, then add ordinary portland cement, silica fume, water glass, redispersible latex powder, granulated blast furnace slag, make the mixer rotate at a speed of 57~67r / min, and stir for 20 ~40s; add quartz sand evenly into the mixing tank and continue stirring for 20-40s; stop stirring for 90s, adjust the speed of the mixer to 115-135r / min, scrape the slurry to the middle of the mixing tank, and continue stirring for 50 ~70s, the waterproof coating is obtained.

[0031] The existing cement-based osmotic crystalline waterproof material mainly uses the osmotic crystallization effect of active chemical substances in its composition to achieve the purpose of...

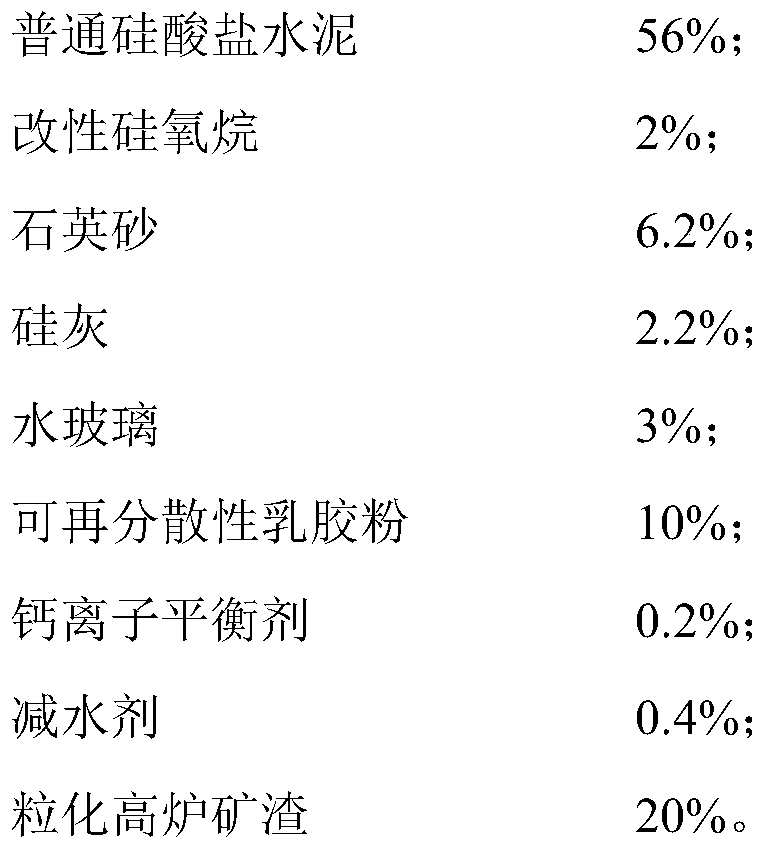

Embodiment 1

[0038] The percentage by weight of each component of the infiltration crystalline waterproof material obtained in the present embodiment is as follows: 56% of ordinary Portland cement, 2% of modified siloxane, 6.2% of quartz sand, 2.2% of silica fume, 3% of water glass, The modulus is 0.5, the redispersible latex powder is 10%, the calcium ion balancer is 0.2%, the water reducer is 0.4%, and the granulated blast furnace slag is 20%. Among them, calcium hydroxide is used as calcium ion balancer, and powdered sulfamate water reducer is used as water reducer; when the fineness modulus of quartz sand is controlled to be 2-2.3 and 2.3-3.0, the mass percentages are respectively 20%, 80%; the mass percentage of blast furnace slag is 10% and 90% when the mesh number of blast furnace slag is controlled to be 200-300 mesh, and 300 mesh and above.

[0039] Use a planetary plastic sand mixer, wipe the mixing blade and the mixing bucket with a clean damp cloth before mixing, first add the ...

Embodiment 2

[0042] The percentage by weight of each component of the permeable crystalline waterproof material obtained in the present embodiment is as follows: 45% of ordinary Portland cement, 3% of modified siloxane, 10% of quartz sand, 1.8% of silica fume, 1% of water glass, The modulus is 0.5, the redispersible latex powder is 8.1%, the calcium ion balancer is 0.4%, the water reducer is 0.7%, and the granulated blast furnace slag is 30%. Among them, calcium hydroxide is used as calcium ion balancer, and powdered sulfamate water reducer is used as water reducer; when the fineness modulus of quartz sand is controlled to be 2-2.3 and 2.3-3.0, the mass percentages are 40%, 60%; the mass percentages of blast furnace slag are 30% and 70% when the mesh number of blast furnace slag is controlled to be 200-300 mesh, and 300 mesh and above.

[0043] Use a planetary plastic sand mixer, wipe the mixing blade and the mixing bucket with a clean damp cloth before mixing, first add the modified silox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com