Low-friction low-temperature heat-sealing BOPET film and preparation method thereof

A low-temperature heat-sealing, low-friction technology, used in chemical instruments and methods, lamination, layered products, etc., can solve problems such as affecting food hygiene, affecting health, and increasing packaging costs, improving optical performance and reducing heat sealing. Energy consumption and the effect of solving large surface friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

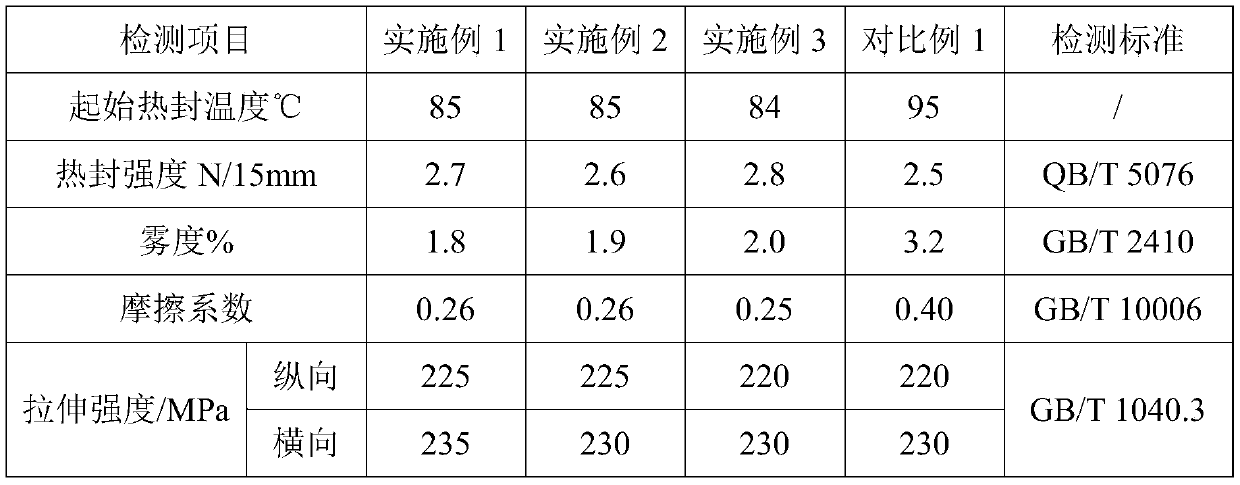

Examples

Embodiment 1

[0021] A low-friction, low-temperature heat-sealing BOPET film is composed of an upper surface layer, a core layer and a lower surface layer.

[0022] The upper surface layer is an anti-adhesive layer, which is composed of the following raw materials by weight percentage: 45% of bright polyester chips, 5% of smooth masterbatch, and 50% of anti-adhesive masterbatch. Wherein the smooth masterbatch comprises the following raw materials in weight percentage: 2% of pentaerythritol stearate, and the balance of bright polyester chips. The anti-adhesive masterbatch includes raw materials in the following percentages by weight: 4% spherical transparent glass beads, and a large amount of bright polyester chips; the particle diameter of the spherical transparent glass beads is 2.0-2.5 μm.

[0023] The raw material of the core layer is bright polyester chips.

[0024] The lower surface layer is a low-temperature heat-sealing layer, and the raw material is a copolymerized modified PETG po...

Embodiment 2

[0032] A low-friction, low-temperature heat-sealing BOPET film is composed of an upper surface layer, a core layer and a lower surface layer.

[0033] The upper surface layer is an anti-adhesive layer, which is composed of the following raw materials by weight percentage: 40% of bright polyester chips, 10% of smooth masterbatch, and 50% of anti-adhesive masterbatch. Wherein the smooth masterbatch comprises the following raw materials in percentage by weight: 3% of pentaerythritol stearate, and the balance of bright polyester chips. The anti-adhesive masterbatch includes the following raw materials in weight percentage: 5% of spherical transparent glass beads, and a large amount of bright polyester chips; the particle diameter of spherical transparent glass beads is 2.0-2.5 μm.

[0034] The raw material of the core layer is bright polyester chips.

[0035] The lower surface layer is a low-temperature heat-sealing layer, and the raw material is a copolymerized modified PETG pol...

Embodiment 3

[0043] A low-friction, low-temperature heat-sealing BOPET film is composed of an upper surface layer, a core layer and a lower surface layer.

[0044] The upper surface layer is an anti-adhesive layer, which is composed of the following raw materials by weight percentage: 50% of bright polyester chips, 10% of smooth masterbatch, and 40% of anti-adhesive masterbatch. Wherein the smooth masterbatch comprises the following raw materials in weight percentage: 4% of pentaerythritol stearate, and the balance of bright polyester chips. The anti-adhesive masterbatch includes the following raw materials in weight percentage: 6% spherical transparent glass beads, and a large amount of bright polyester chips; the particle diameter of the spherical transparent glass beads is 2.0-2.5 μm.

[0045] The raw material of the core layer is bright polyester chips.

[0046] The lower surface layer is a low-temperature heat-sealing layer, and the raw material is a copolymerized modified PETG polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com