Preparation method of a corrosion-resistant, waterproof, and flame-retardant elastic coil

A corrosion-resistant and coiled material technology, which is applied to flat products, other household appliances, coatings, etc., can solve the problems of waterproof membrane performance degradation, interference with biological endocrine, and reproductive function, and improve processing performance and corrosion resistance. , shorten the plasticizing time, the effect of not easy to migrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

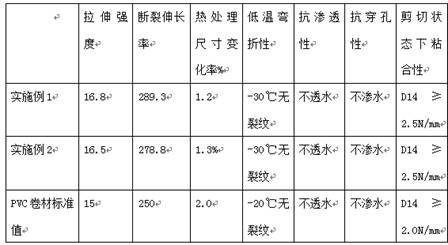

Examples

Embodiment 1

[0020] A method for preparing a corrosion-resistant, waterproof, and flame-retardant elastic coil, comprising the following steps:

[0021](1) In the polymerization reactor, replace the inside of the reactor with nitrogen to form an oxygen-free atmosphere. Mix 15 parts of vinyl acetate monomer, 0.1 part of initiator azobisisobutyronitrile, emulsifier dodecylbenzenesulfonate Add 0.4 parts of sodium bicarbonate and 23 parts of water into the emulsification tank for emulsification to obtain an emulsion, add the emulsion and 83 parts of vinyl chloride monomer into the polymerization tank, keep the reaction pressure at 0.4 MPa, stir evenly, raise the temperature to 80°C, and polymerize for 1 hour. Add a certain amount of sodium nitrite to ensure that the concentration of sodium nitrite in the whole system is 1.2g / mL, cool down to 75°C, stir and react, use methanol to break the emulsion, and then heat and vacuum the unreacted residual vinyl chloride mono body and demulsifier methano...

Embodiment 2

[0030] A method for preparing a corrosion-resistant, waterproof, and flame-retardant elastic coil, comprising the following steps:

[0031] (1) In the polymerization reactor, replace the inside of the reactor with nitrogen to form an oxygen-free atmosphere. Mix 12 parts of vinyl acetate monomer, 0.05 part of initiator azobisisobutyronitrile, emulsifier dodecylbenzenesulfonate Add 0.2 parts of sodium bicarbonate and 15 parts of water into the emulsification kettle for emulsification to obtain an emulsion, add the emulsion and 83 parts of vinyl chloride monomer into the polymerization kettle, keep the reaction pressure at 0.2MPa, stir evenly, raise the temperature to 75°C, and polymerize for 0.5h , add a certain amount of sodium nitrite to ensure that the concentration of sodium nitrite in the whole system is 1.2g / mL, cool down to 65°C, stir and react, use methanol to break the emulsion, and then heat and vacuum the unreacted residual vinyl chloride through a closed settling tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com