Manganese oxide catalyst, and preparation method and application thereof

A manganese oxide and catalyst technology, applied in the field of manganese oxide catalyst preparation, can solve the problems of high light-off temperature, complicated preparation method, etc., and achieve the effects of less pollution, environmental friendliness, and simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

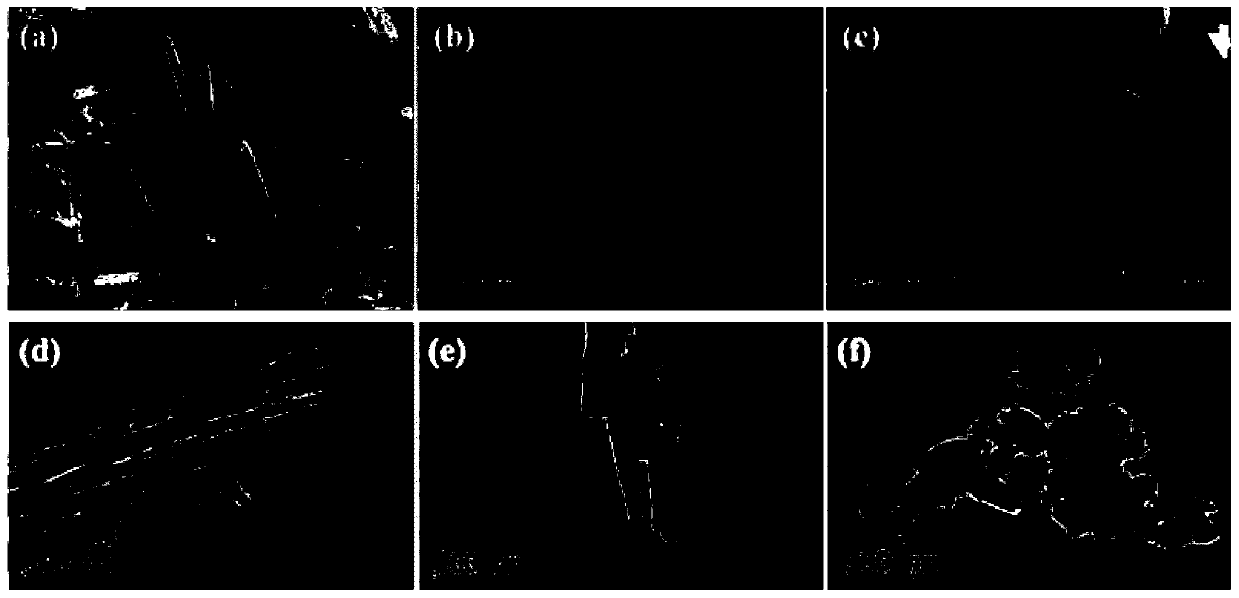

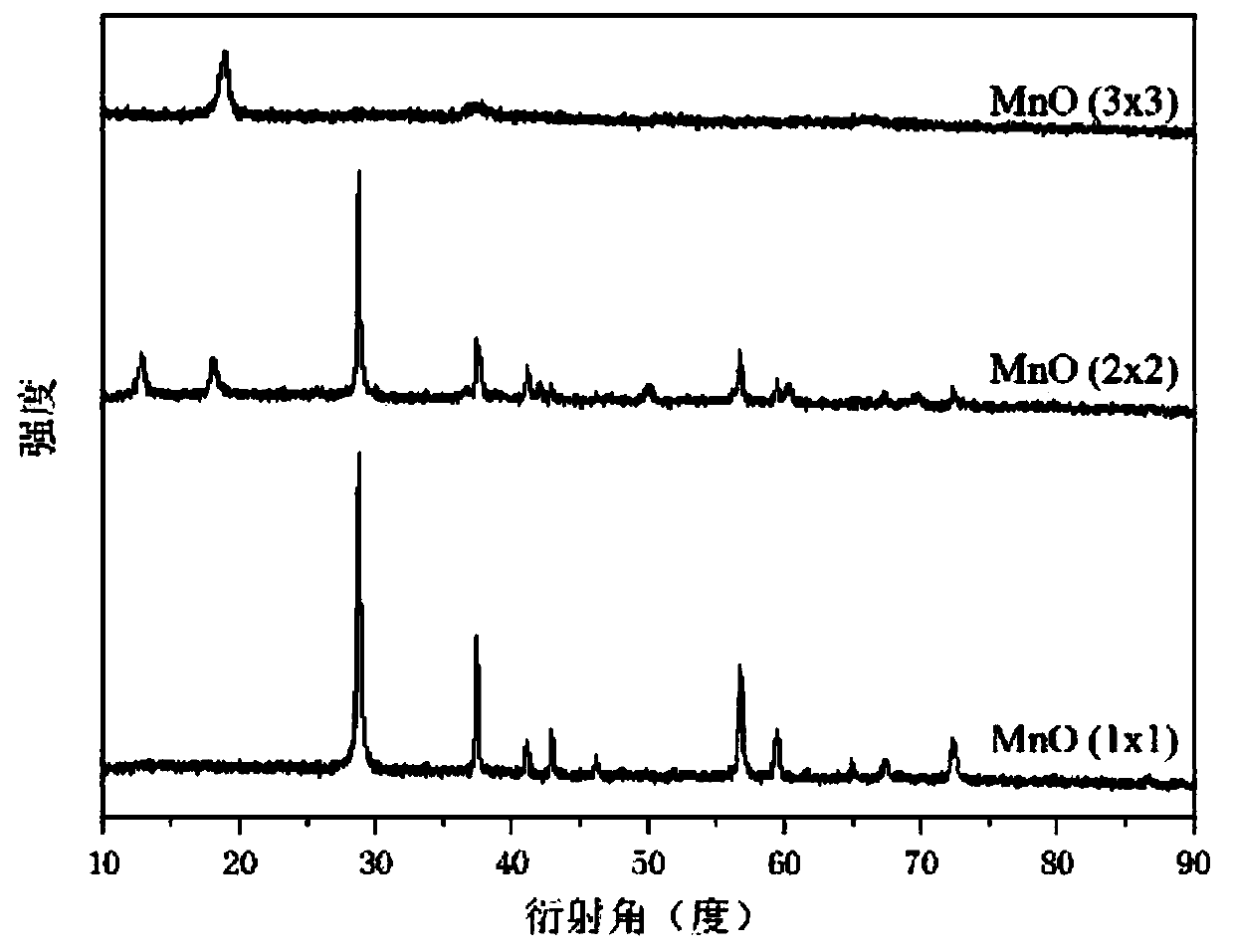

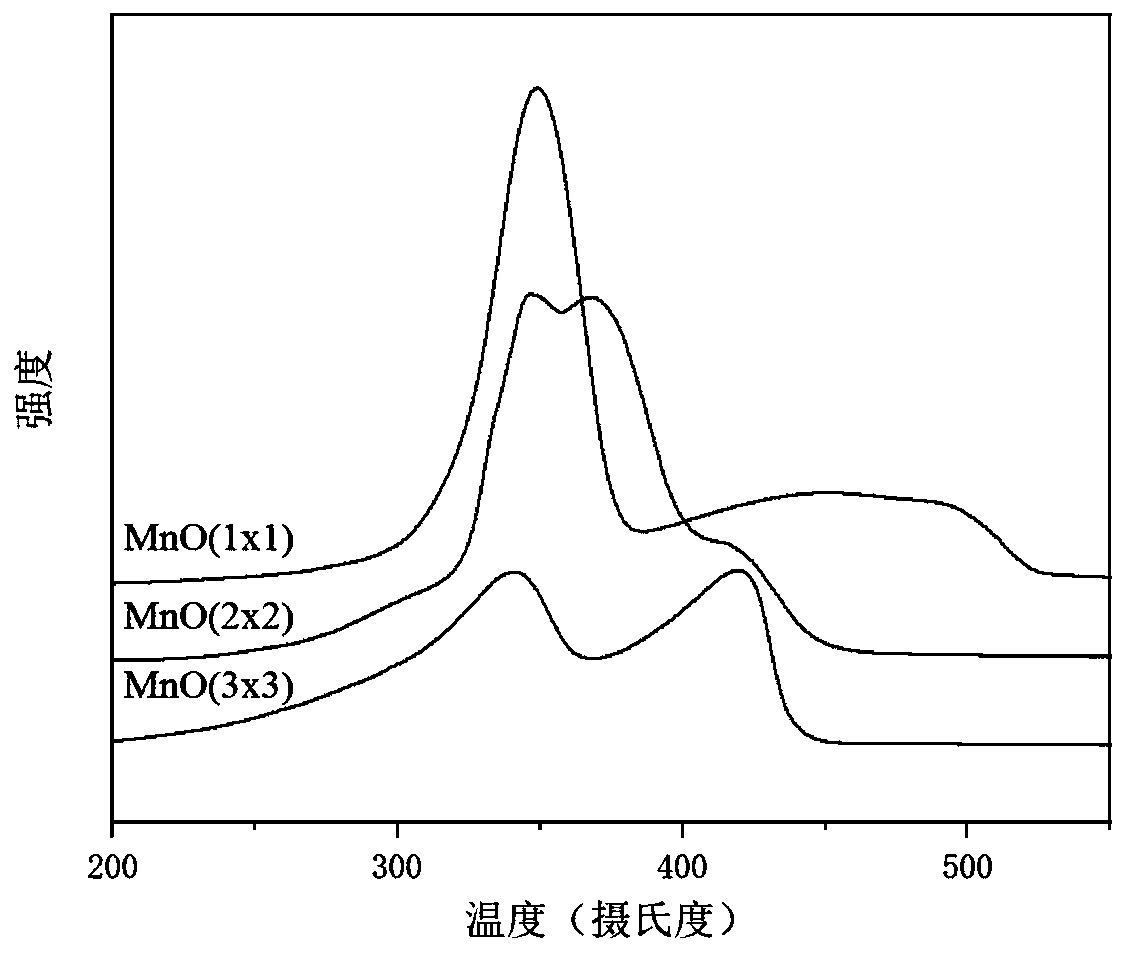

[0034] Preparation of MnO(1x1) catalyst:

[0035] Accurately weigh 3.93g (NH 4 ) 2 S 2 o 8 and 2.91g MnSO 4 ·H 2 O was respectively dissolved in 70mL deionized water. After ultrasonic dispersion, the manganese sulfate solution was added dropwise to the ammonium persulfate solution with a constant pressure dropping funnel, and stirred while adding. After the solution was uniformly mixed, it was transferred to a high-pressure reaction kettle. , reacted at 140°C for 12h, cooled to room temperature, separated by filtration, washed with distilled water, dried at 80°C, and then calcined at 400°C for 4h in an air atmosphere in a muffle furnace to obtain MnO (1x1) catalyst.

Embodiment 2

[0037] Preparation of MnO(2x2) catalyst

[0038] Accurately weigh 1.24g MnSO 4 ·H 2 O and 0.83 g KMnO 4 Dissolve in 20mL deionized water respectively. After ultrasonic dispersion, the manganese sulfate solution was added dropwise to the potassium permanganate solution with a constant pressure dropping funnel, and stirred while adding. After the solution was uniformly mixed, it was transferred to a high-pressure reactor. Reacted at 160°C for 24h, cooled to room temperature, separated by filtration, washed with distilled water, dried at 80°C, and then calcined at 400°C for 4h in an air atmosphere in a muffle furnace to prepare the MnO(2x2) catalyst.

Embodiment 3

[0040] Preparation of MnO(3x3) catalyst

[0041] a) Accurately weigh 3.96g MnCl·H2 O and 1.63g MgCl 6H 2 O was respectively dissolved in 20mL deionized water, and after ultrasonic dispersion, the manganese chloride solution was added dropwise to the magnesium chloride solution with a constant pressure dropping funnel, and stirred while adding;

[0042] b) Accurately weigh 10.00g of NaOH and dissolve it in 50mL of deionized water, and add it dropwise to the above solution;

[0043] c) Accurately weigh 1.26g KMnO 4 After dissolving in 40ml deionized water, sonicate for 10min, add dropwise to b), stir at room temperature for 30min, and let stand for aging for 48h;

[0044] d) 1L 1mol / L MgCl 2 The solution was dropped into the mixed solution of step c), stirred at room temperature for 10 h, then transferred to an autoclave, reacted at 150 ° C for 48 h, cooled to room temperature, separated by filtration, washed with distilled water, dried overnight at 110 ° C, and then placed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com