Flue with purification function and iron and steel smelting equipment

A flue and functional technology, applied in the direction of chemical instruments and methods, dispersed particle filtration, membrane filter, etc., can solve the problems of pollution, general convenience, etc., and achieve the effect of improving purification speed, good stability, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

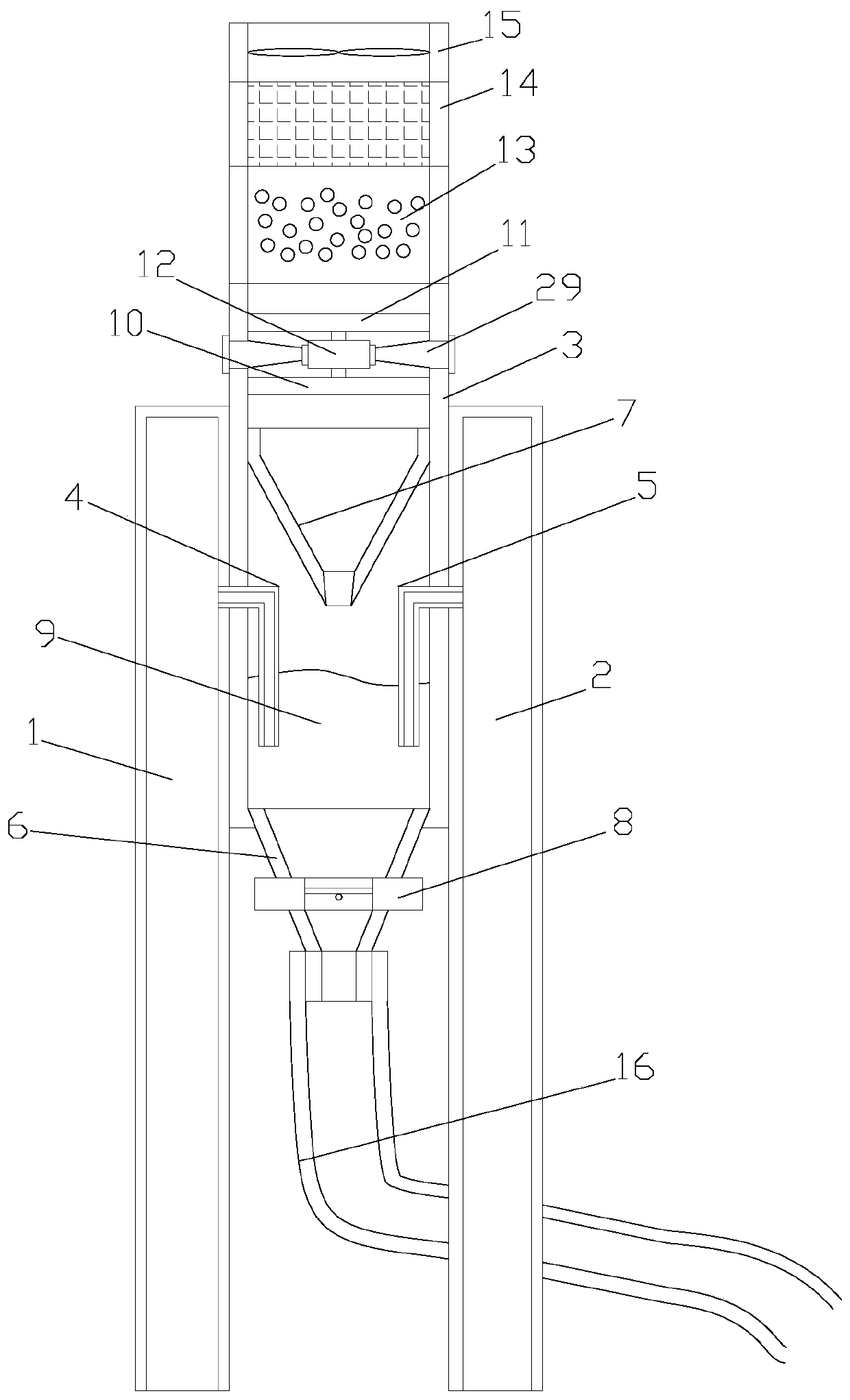

[0028] Such as figure 1As shown, a flue with purification function includes a first smoke inlet pipe 1, a second smoke inlet pipe 2 and an exhaust pipe 3, and the tops of the first smoke inlet pipe 1 and the second smoke inlet pipe 2 are both Sealing arrangement, the first smoke inlet pipe 1 and the second smoke inlet pipe 2 are fixedly connected with the exhaust pipe 3, and the first air inlet pipe 4, the second air inlet pipe 5, the first Funnel 6 and second funnel 7, described first funnel 6 is provided with butterfly valve 8, is formed with storage chamber 9 between described first funnel 6 and second funnel 7, is provided with reaction liquid ( not shown), one end of the first air inlet pipe 4 and the second air inlet pipe 5 is inserted into the reaction liquid, and the other end of the first air inlet pipe 4 and the second air inlet pipe 5 runs through the first smoke inlet pipe 1 and the second air inlet pipe respectively. The smoke pipe 2, the first smoke inlet pipe 1...

Embodiment 2

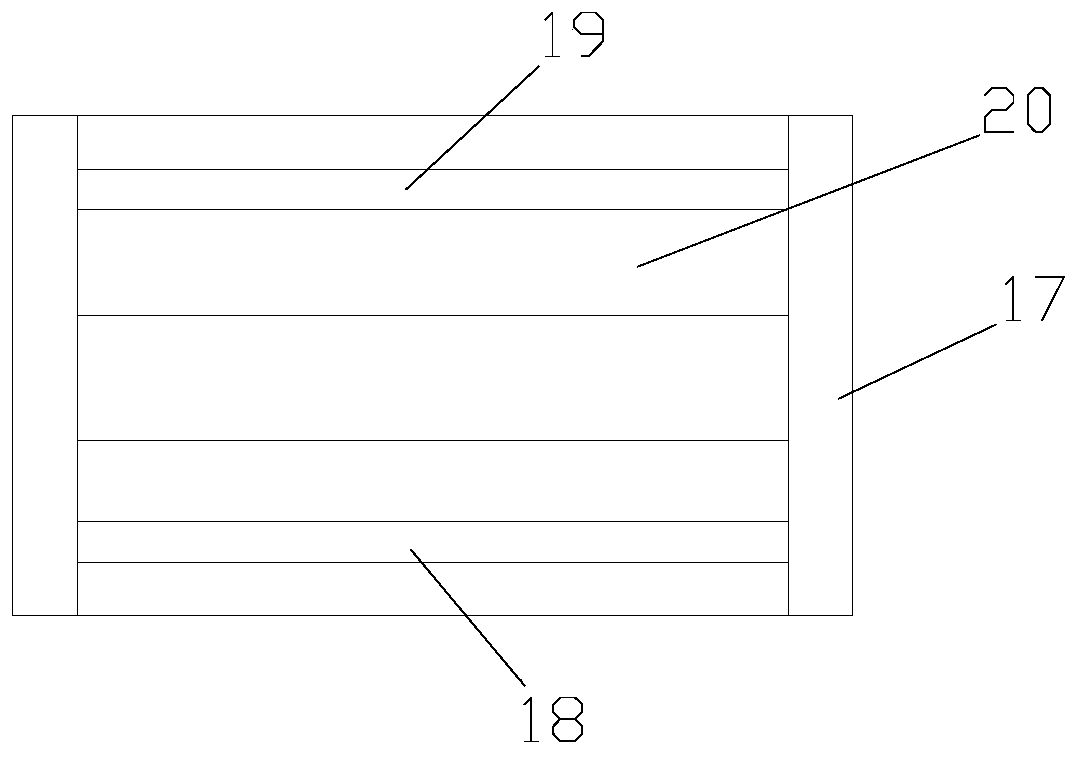

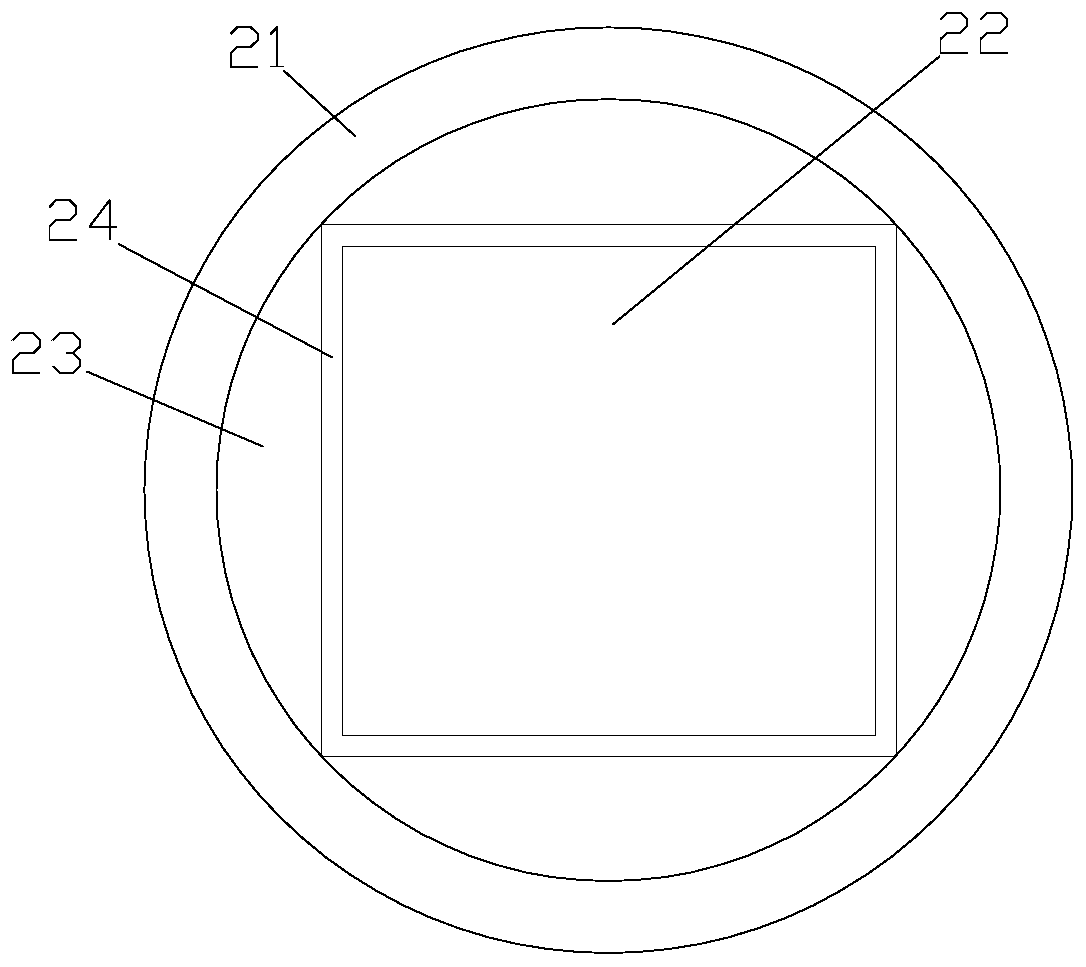

[0031] like Figure 1-5 As shown, a flue with purification function includes a first smoke inlet pipe 1, a second smoke inlet pipe 2 and an exhaust pipe 3, and the tops of the first smoke inlet pipe 1 and the second smoke inlet pipe 2 are both Sealing arrangement, the first smoke inlet pipe 1 and the second smoke inlet pipe 2 are fixedly connected with the exhaust pipe 3, and the first air inlet pipe 4, the second air inlet pipe 5, the first Funnel 6 and second funnel 7, described first funnel 6 is provided with butterfly valve 8, is formed with storage chamber 9 between described first funnel 6 and second funnel 7, is provided with reaction liquid ( not shown), one end of the first air inlet pipe 4 and the second air inlet pipe 5 is inserted into the reaction liquid, and the other end of the first air inlet pipe 4 and the second air inlet pipe 5 runs through the first smoke inlet pipe 1 and the second air inlet pipe respectively. The smoke pipe 2, the first smoke inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com