Water circulation system and water circulation treatment method for box paperboard production

A technology of water circulation and production box, applied in pulp beating/refining method, fiber raw material treatment, papermaking, etc., can solve the problems of bacterial growth and other problems, and achieve the effect of improving retention, reducing COD, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present application will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present application and implement it, but the embodiments are not intended to limit the present application.

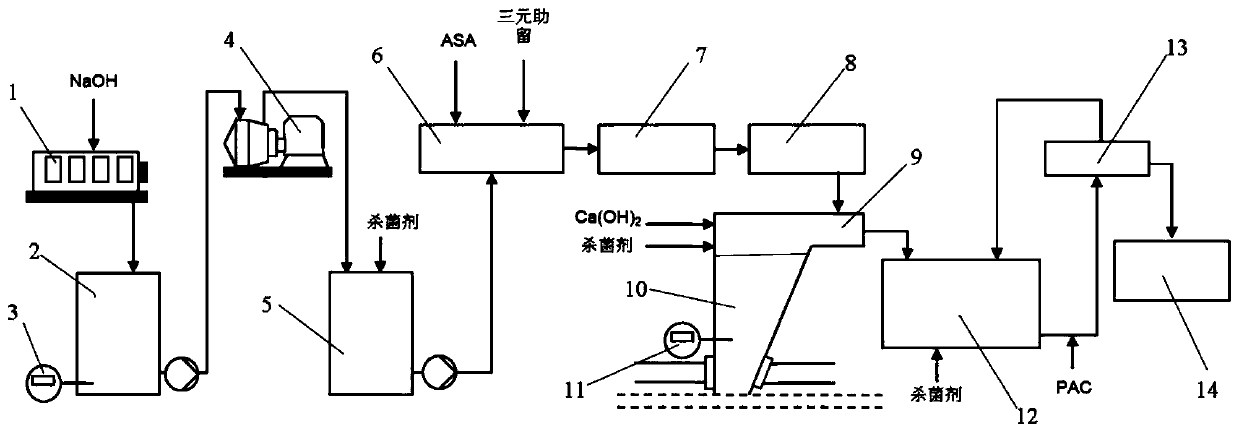

[0022] like figure 1 As shown, in order to solve the above-mentioned technical problems, the application provides a water circulation system for producing container boards. The water circulation system includes a heat dispersion device, a heat dispersion pulp pool, a disc mill, a tap pool, The flow delivery system, the headbox, the net part, the white water tray under the net, the flushing tank, the heat dispersing device and the white water tray under the net are all provided with alkaline solution addition points for adding alkaline solution. The heat dispersion tank is provided with a first PH meter, and the first pH meter is used to monitor the pH change of the slurry in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com