Device and method for continuous and controllable synthesis of uniform nanocrystalline at normal temperature

A nanocrystalline, normal temperature technology, applied in the direction of nanotechnology, nano-optics, nanotechnology, etc., can solve the problems that the magnetic heating stirrer cannot accurately control the reaction time and temperature, the high-temperature reaction consumes a lot of energy, and the post-processing process is cumbersome. Low cost, avoid high temperature heating, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

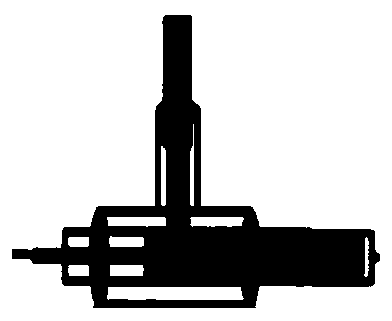

[0041] Provides a device for continuous and controllable synthesis of uniform nanocrystals at room temperature, including: lead bromide precursor injector (1), Cs precursor injector (2), through a dual-channel syringe pump (3), capillary microfluidic chip microreactor (5), ultrasonic device (6), collecting device (7). The lead bromide precursor injector (1) and the Cs precursor injector (2) are connected to two inlets of a dual-channel syringe pump, and the outlet of the dual-channel syringe pump is connected to the capillary microfluidic chip microreactor (5 ), the outlet of the capillary microfluidic chip microreactor is connected to a polytetrafluoroethylene connecting pipe, the middle part of the connecting pipe is placed in the ultrasonic device, and the tail of the polytetrafluoroethylene connecting pipe is connected to the collection device connected.

[0042] Further, the inner diameter of the polytetrafluoroethylene connecting tube (4) matches the outlet of the capil...

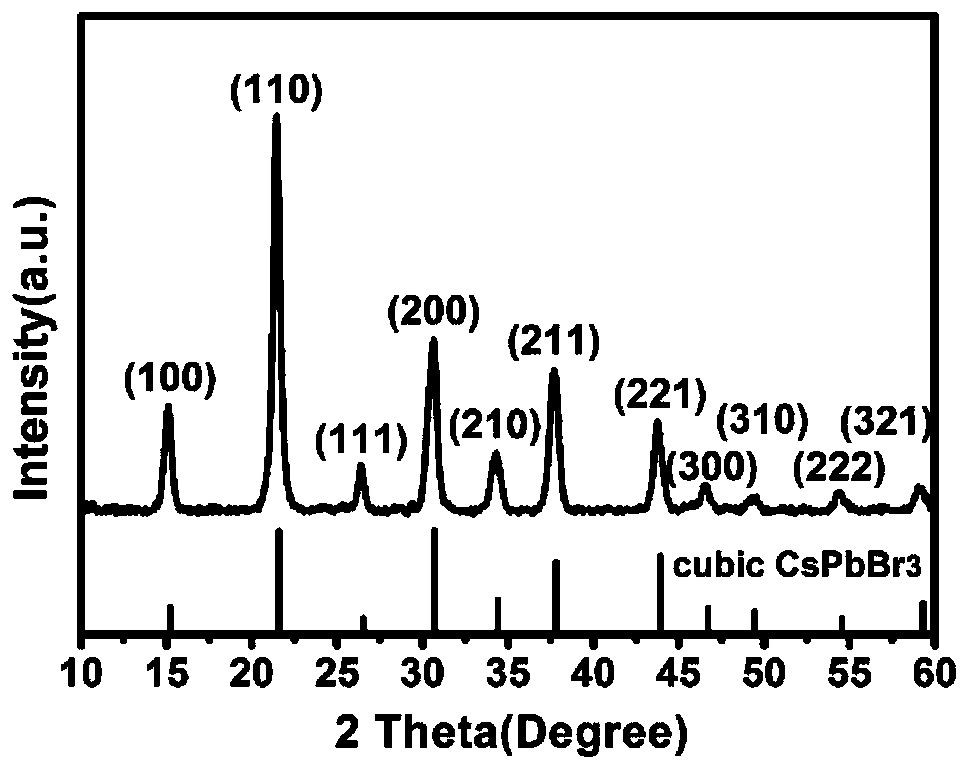

Embodiment 2

[0050] 1) configure the lead bromide precursor, and analyze the pure PbBr 2 Dissolve in 1-octadecene, add a certain amount of oleic acid and oleylamine after heating under nitrogen atmosphere for a certain period of time, and wait for PbBr 2 Cool to room temperature after complete dissolution;

[0051] 2) Configure the Cs precursor and analyze the pure Cs 2 CO 3 Dissolve in 1-octadecene, add a certain amount of oleic acid after heating for a certain period of time under nitrogen atmosphere, and wait until Cs 2 CO 3 Completely dissolve the solution and cool to room temperature after clarification;

[0052] 3) Put the prepared lead bromide precursor and Cs precursor into the lead bromide precursor injector (1) and the Cs precursor injector (2) respectively, and the lead bromide precursor and the Cs precursor are mixed at 2-10mL / Inject at a suitable flow rate of h, enter the capillary microfluidic chip microreactor (5) and mix evenly, then place it in the ultrasonic device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com