A method for increasing the porosity of low-quality activated carbon

A kind of activated carbon, low-quality technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems that are difficult to meet the application requirements of supercapacitors, high micropore content, low porosity, etc., and meet industrial mass production Requirements, simple operation, and the effect of improving porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

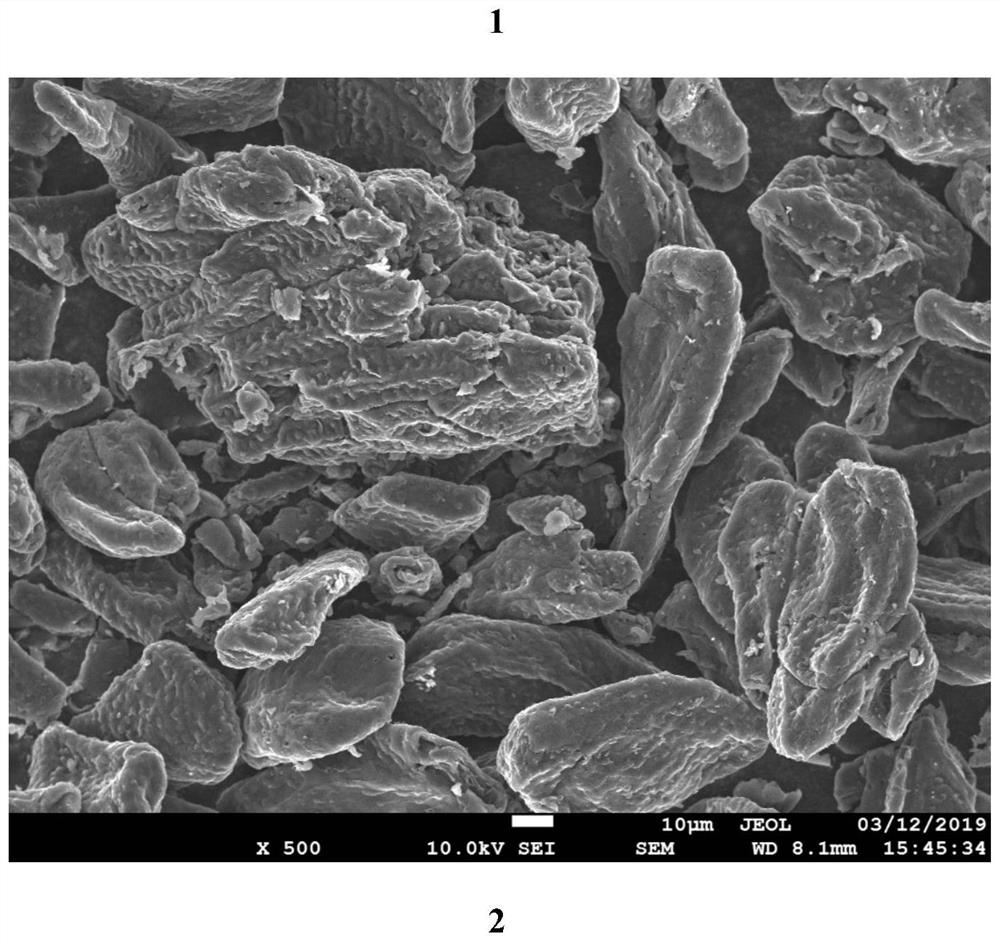

[0047] 1. The process of carbon dioxide activation to prepare activated carbon is as follows:

[0048] Coconut shells were selected as the carbon source of the precursor, peeled, and the main part was taken, washed several times with distilled water, dried in an oven at 120°C for 24 hours, and then crushed by a pulverizer (6000r / min, 30min). Pulverize and sieve out 325 mesh coconut shell powder. Put the carbon source in a tube furnace, raise the temperature to 900°C at 10°C / min in an argon atmosphere, perform high-temperature activation treatment in a 1L / min carbon dioxide atmosphere for 2 hours, and then lower the temperature in an argon atmosphere. The product was washed three times with 1 mol / L HCl and twice with water until neutral, then filtered and dried in vacuum at 120°C for 12 hours.

[0049] 2. The alkane pore expansion process is as follows:

[0050] Using coconut shell activated carbon as raw material, in the atmosphere of the mixed gas of butane and argon (volum...

Embodiment 2

[0070] The process of carbon dioxide activation to prepare activated carbon is as in Example 1.

[0071] Coconut shell activated carbon was used as raw material, and the temperature was raised to 500°C for 1h at a heating rate of 5°C / min in an atmosphere of a mixture of pentane and argon (1:8). After the calcination, the coconut shell activated carbon after the pore size adjustment was completed was soaked in 1mol / L hydrochloric acid solution for 12 hours to remove inorganic impurities. Rinse with deionized water until neutral, collect the black solid by filtration, dry in a vacuum oven at 80° C. to obtain the coconut shell activated carbon with regulated pore size.

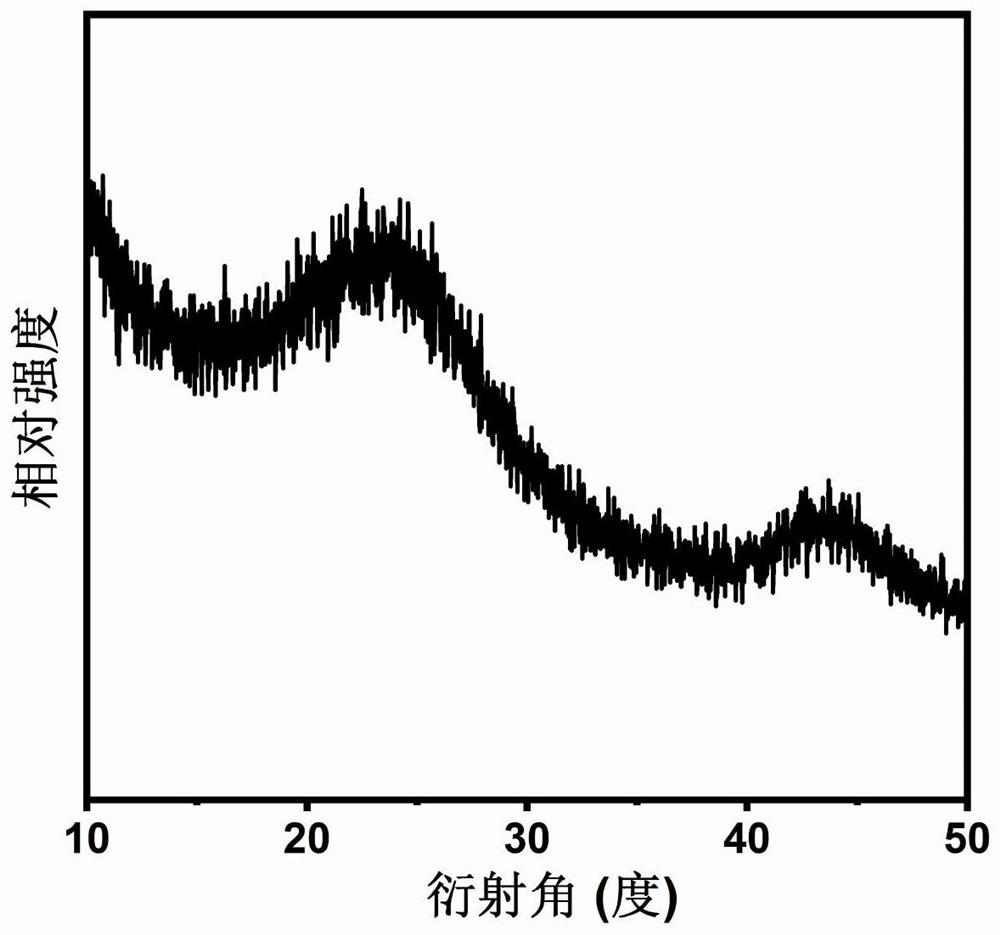

[0072] The process of reducing activated carbon with argon and hydrogen mixed gas is as in Example 1, and the BET test spectrum of the final obtained activated carbon is as follows image 3 As shown, the PSD test pattern is as Figure 4 shown.

[0073] Conclusion: The BET test pattern and PSD test pattern of a...

Embodiment 3

[0075] The process of carbon dioxide activation to prepare activated carbon is as in Example 1.

[0076] Using coconut shell activated carbon as raw material, in the atmosphere of the mixed gas of hexane and argon (1:8), the temperature was raised to 500°C at a heating rate of 5°C / min and kept for 1h. After the calcination, the coconut shell activated carbon after the pore size adjustment was completed was soaked in 1mol / L hydrochloric acid solution for 12 hours to remove inorganic impurities. Rinse with deionized water until neutral, collect the black solid by filtration, dry in a vacuum oven at 80° C. to obtain the coconut shell activated carbon with regulated pore size.

[0077] The process of reducing activated carbon with argon-hydrogen mixed gas is as in Example 1.

[0078] The obtained low-cost high-quality activated carbon, conductive carbon black and binder are added to an appropriate amount of NMP in a mass ratio of 70:15:15, mixed and ground to obtain a uniform ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com