Sheet special for tobacco product and preparation method thereof

A technology for tobacco products and sheets, applied in the field of special sheets for tobacco products and their preparation, can solve problems such as the uniformity and stability of smoke emission that cannot be effectively solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

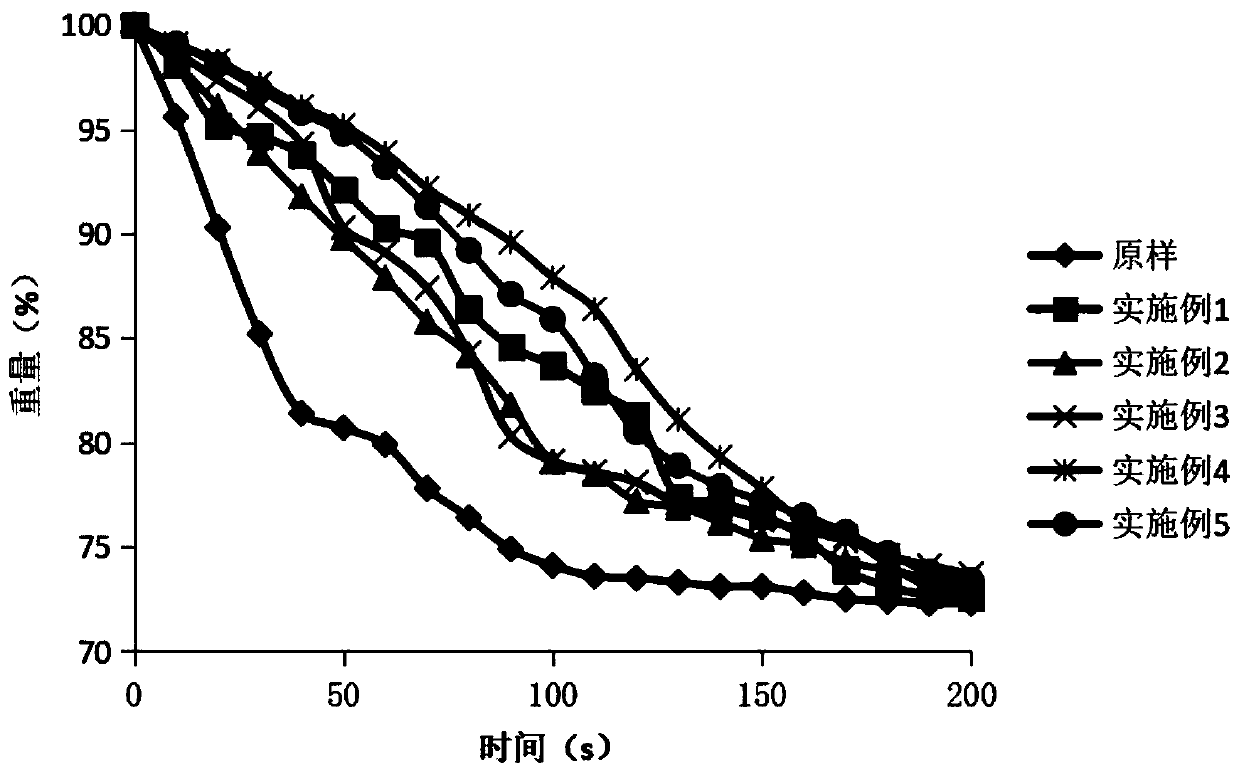

Examples

Embodiment 1

[0021] In this embodiment one, the preparation method of the special sheet for tobacco products specifically includes the following steps:

[0022] (1) tobacco leaves are pulverized into smoke powder;

[0023] (2) According to the weight ratio of smoke powder: water=1:5, fully mix in the homogeneous reaction tank;

[0024] (3) Take the broad-leaved wood fiber according to 7% of the weight of the smoke powder, use a disc mill to beat to 25 ° SR, and then add it to the homogeneous reaction tank after being dispersed by a homogeneous pump to mix evenly with the materials in step (2);

[0025] (4) Propylene glycol is weighed according to 20% of the smoke powder weight, added to a homogeneous reaction tank and mixed evenly with the materials in step (3);

[0026] (5) Take sodium alginate according to 5% of the weight of tobacco powder, and prepare a solution with a concentration of 2%;

[0027] (6) Add the solution prepared in the step (5) to the homogeneous reaction tank and mix...

Embodiment 2

[0041] In the second embodiment, the preparation method of the special sheet for tobacco products specifically includes the following steps:

[0042] (1) tobacco leaves are pulverized into smoke powder;

[0043] (2) According to the weight ratio of smoke powder: water=1:10, fully mix in the homogeneous reaction tank;

[0044] (3) Take the coniferous wood fiber according to 2% of the weight of the smoke powder, use a disc mill to beat to 23 ° SR, and then add it to the homogeneous reaction tank after being dispersed by a homogeneous pump to mix evenly with the materials in step (2);

[0045] (4) Glycerin is weighed according to 40% of the smoke powder weight, added to a homogeneous reaction tank and mixed evenly with the materials in step (3);

[0046] (5) take guar gum according to 8% of tobacco powder weight, and be mixed with the solution of 2% concentration;

[0047] (6) Add the solution prepared in the step (5) to the homogeneous reaction tank and mix the materials in th...

Embodiment 3

[0061] In this embodiment three, the preparation method of the special sheet for tobacco products specifically includes the following steps:

[0062] (1) tobacco leaves are pulverized into smoke powder;

[0063] (2) According to the weight ratio smoke powder: water=1:9, fully mix in the homogeneous reaction tank;

[0064] (3) Take the coniferous wood fiber according to 3% of the weight of the smoke powder, use a disc mill to beat to 22 ° SR, and then add it to the homogeneous reaction tank after being dispersed by a homogeneous pump and mix with the material in step (2);

[0065] (4) Propylene glycol is weighed according to 35% of the smoke powder weight, added to a homogeneous reaction tank and mixed with the material in step (3);

[0066] (5) take chitosan according to 3% of smoke powder weight, and be mixed with the solution of 2% concentration;

[0067] (6) Add the solution prepared in the step (5) to the homogeneous reaction tank and mix the materials in the step (4); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com