Oxidized pellet production process and system using chain grate-rotary kiln system

A production process, a technology for oxidizing pellets, applied in the field of pellets, which can solve the problems of production reduction, increased investment cost and operating cost, and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0075] According to the first embodiment of the present invention, a kind of utilization grate machine-rotary kiln system oxidation pellet production process is provided:

[0076] A production process for oxidizing pellets using a grate-rotary kiln system, the grate-rotary kiln system includes a grate 1, a rotary kiln 2, and an annular cooler 3, wherein: according to the material direction, the grate 1 is sequentially It is divided into blast drying section UDD, exhaust drying section DDD, preheating stage TPH, and preheating stage two PH; the ring cooler 3 is divided into ring cooling stage one C1, ring cooling second stage C2 and ring cooling three stage C3; Include the following steps:

[0077] 1) The raw pellets are dried, preheated and oxidized through the grate machine 1, and then the material passed through the grate machine 1 is transported to the rotary kiln 2 for roasting, and then transported to the ring cooler 3 for cooling to obtain pellets;

[0078]2) The hot ai...

Embodiment 1

[0096] A production process for oxidizing pellets using a grate-rotary kiln system, the grate-rotary kiln system includes a grate 1, a rotary kiln 2, and an annular cooler 3, wherein: according to the material direction, the grate 1 is sequentially It is divided into blast drying section UDD, exhaust drying section DDD, preheating stage TPH, and preheating stage two PH; the ring cooler 3 is divided into ring cooling stage one C1, ring cooling second stage C2 and ring cooling three stage C3; Include the following steps:

[0097] 1) The raw pellets are dried, preheated and oxidized through the grate machine 1, and then the material passed through the grate machine 1 is transported to the rotary kiln 2 for roasting, and then transported to the ring cooler 3 for cooling to obtain pellets;

[0098] 2) The hot air discharged from the ring cooling section C1 is transported to the rotary kiln 2, and the hot air discharged from the rotary kiln 2 is transported to the preheating second ...

Embodiment 2

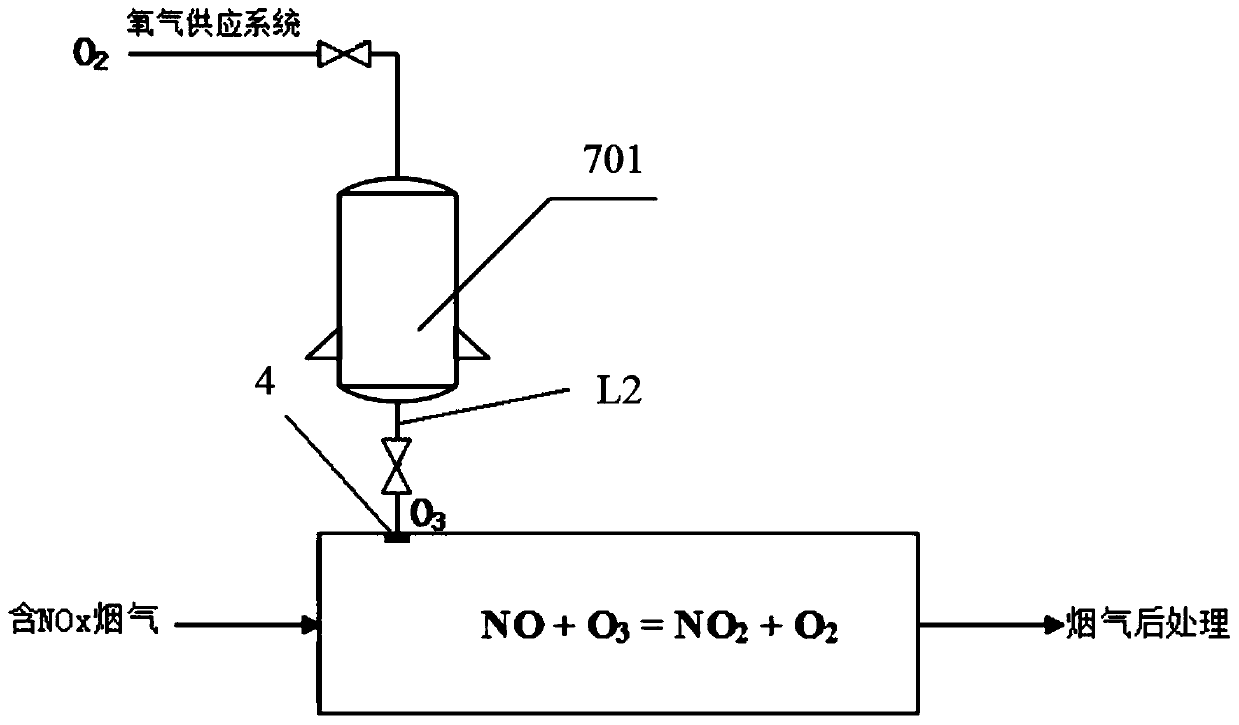

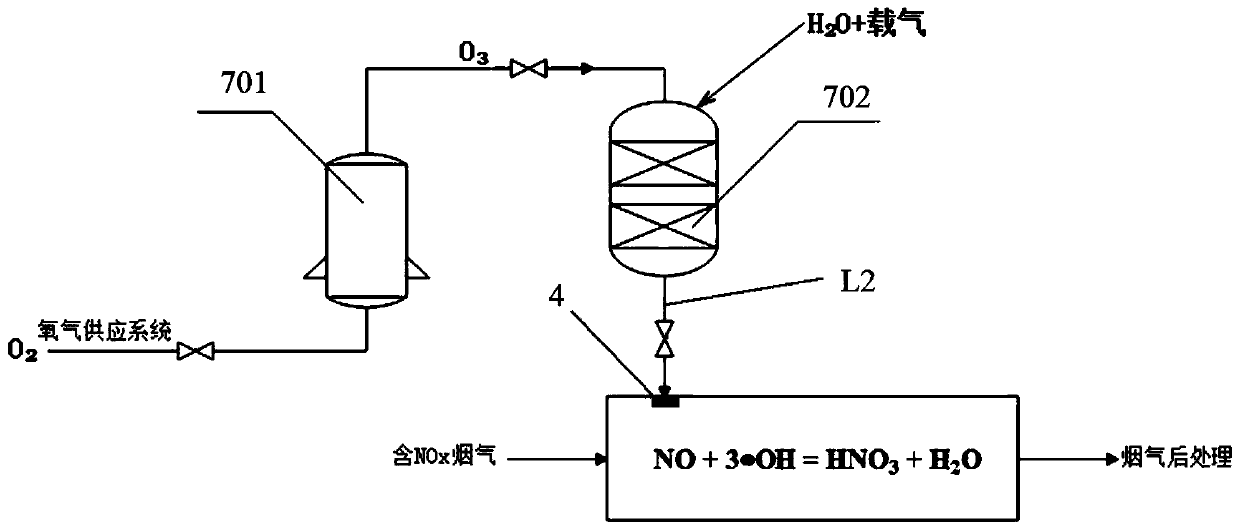

[0102] Example 1 was repeated, except that a denitrification device was installed in the bottom air box of the DDD of the draft drying section, and the denitrification device was an oxidant injector 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com