Automatic production equipment for 3.2-meter wide non-woven fabrics

A production equipment and technology of non-woven fabrics, applied in the direction of non-woven fabrics, melt spinning, textiles and papermaking, etc., can solve the problems of low efficiency, low production level, large gap in manufacturing level, etc., achieve simple operation and improve uniformity Reliability, quality control, stable and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below in conjunction with accompanying drawing:

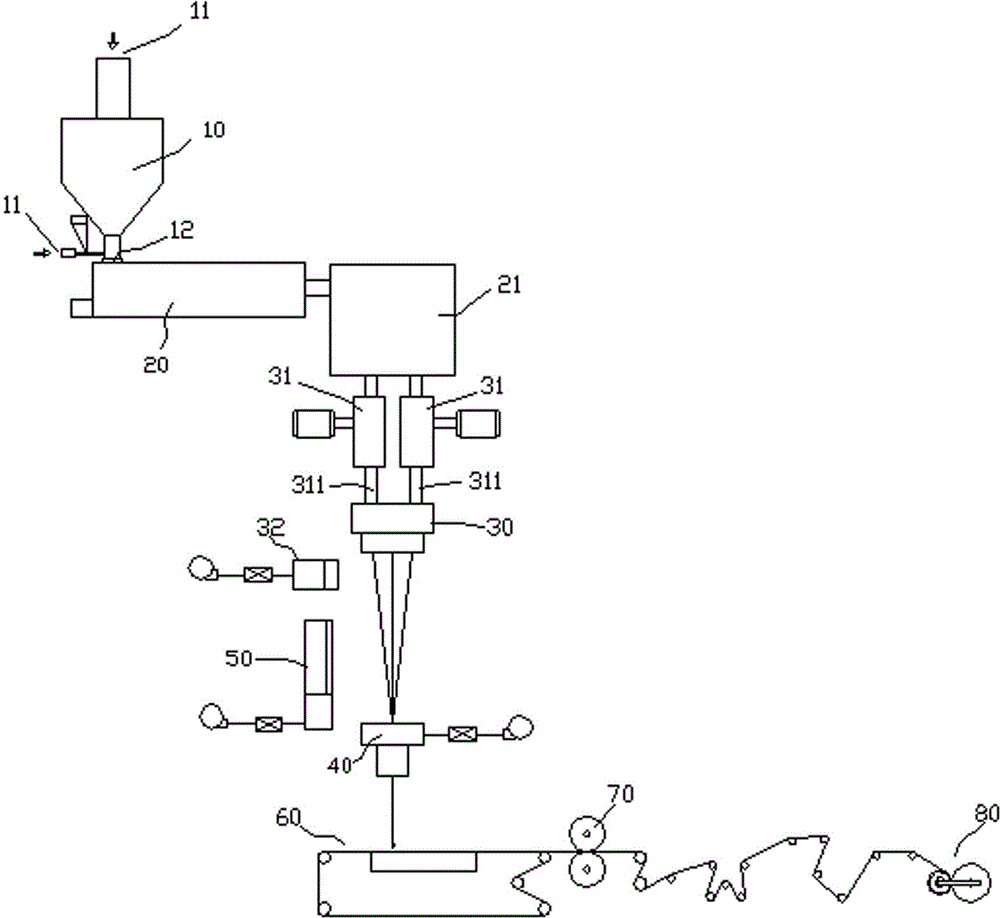

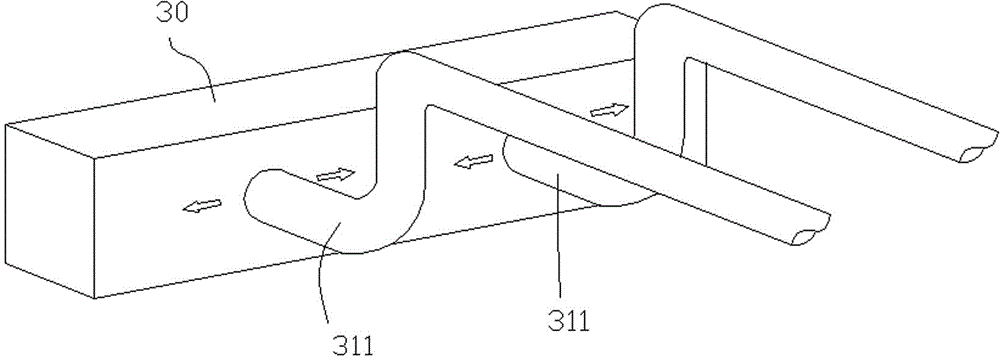

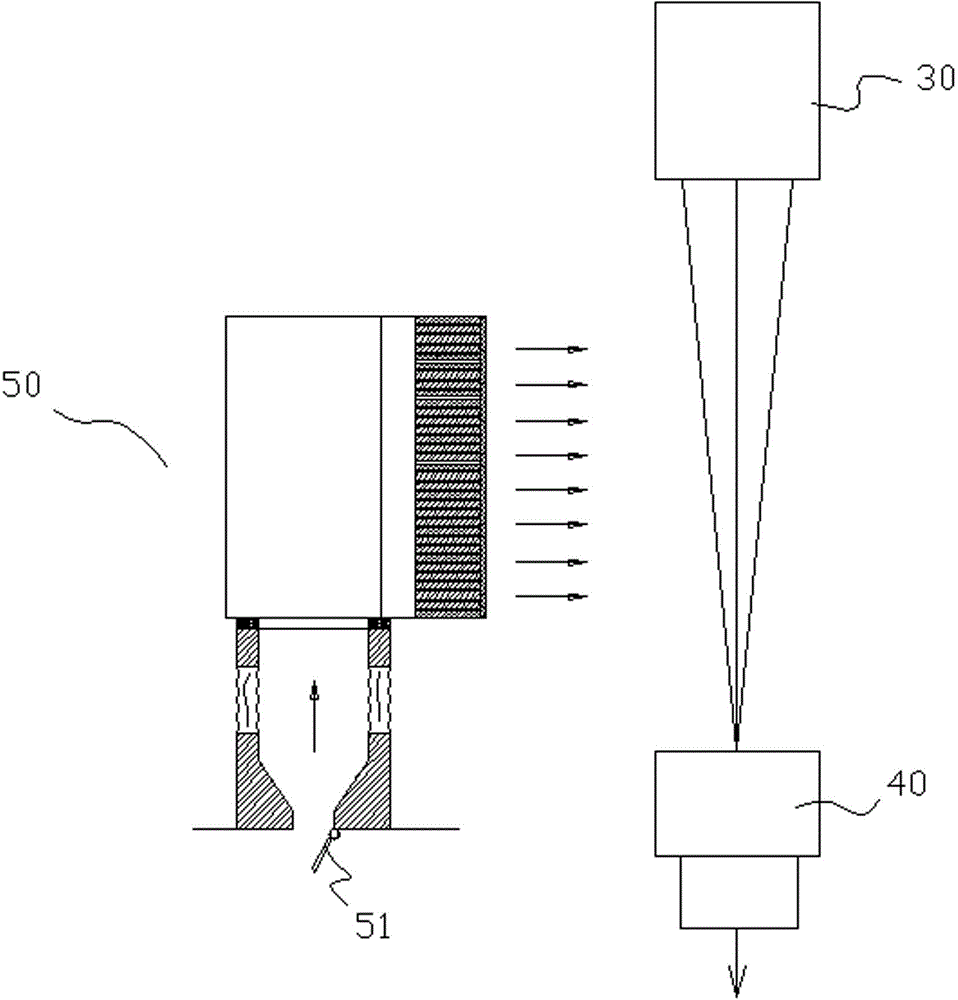

[0027] refer to Figure 1~4 As shown, it is a schematic diagram of the production equipment of the present invention, the automatic production equipment of 3 meters 2 wide non-woven fabrics of the present invention, the equipment adopts PLC programming control, cooperates with corresponding infrared detection, stroke control switch, chain control, sound and light alarm The device improves the stability, reliability and safety of the control system, and adopts a large-screen touch screen control, which makes the operation easier. The present invention includes:

[0028] A feeding unit 10, the feeding unit 10 has one or more feeding ports 11, and a feeding port 12; the feeding unit 10 can accommodate materials such as polypropylene pellets, raw materials and additives through the same or different The injection port 11 is injected, and the material is finally sent out through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com