A production process and system for oxidized pellets using a grate machine-rotary kiln system

A production process and rotary kiln technology, applied in the field of pelletizing, can solve the problems of increased investment cost and operating cost, high NOx removal cost, difference in oxidation degree, etc., and achieve the improvement of quality indicators, small investment, and enhanced oxidation degree and strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0075] According to the first embodiment of the present invention, a kind of utilization grate machine-rotary kiln system oxidation pellet production process is provided:

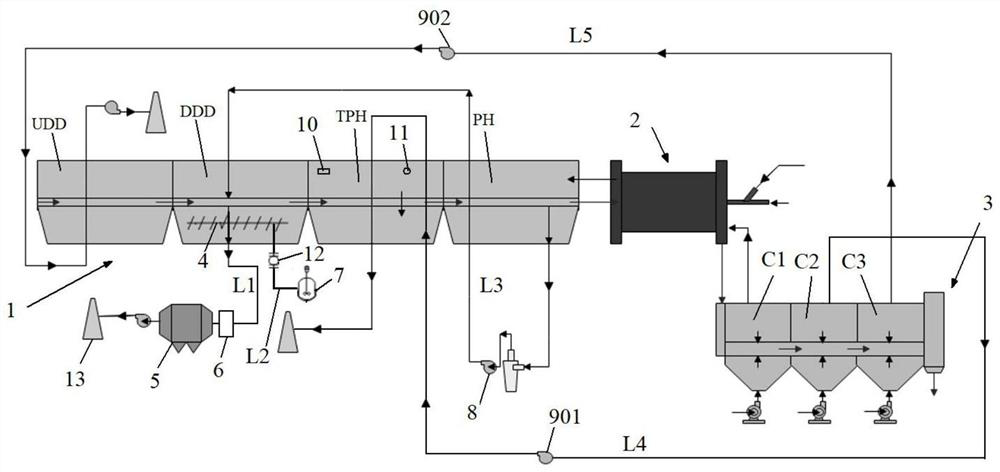

[0076] A production process for oxidizing pellets using a grate-rotary kiln system, the grate-rotary kiln system includes a grate 1, a rotary kiln 2, and an annular cooler 3, wherein: according to the material direction, the grate 1 is sequentially It is divided into blast drying section UDD, exhaust drying section DDD, preheating stage TPH, and preheating stage two PH; the ring cooler 3 is divided into ring cooling stage one C1, ring cooling second stage C2 and ring cooling three stage C3; Include the following steps:

[0077] 1) The raw pellets are dried, preheated and oxidized through the grate machine 1, and then the material passed through the grate machine 1 is transported to the rotary kiln 2 for roasting, and then transported to the ring cooler 3 for cooling to obtain pellets;

[0078]2) The hot ai...

Embodiment 1

[0096] A production process for oxidizing pellets using a grate-rotary kiln system, the grate-rotary kiln system includes a grate 1, a rotary kiln 2, and an annular cooler 3, wherein: according to the material direction, the grate 1 is sequentially It is divided into blast drying section UDD, exhaust drying section DDD, preheating stage TPH, and preheating stage two PH; the ring cooler 3 is divided into ring cooling stage one C1, ring cooling second stage C2 and ring cooling three stage C3; Include the following steps:

[0097] 1) The raw pellets are dried, preheated and oxidized through the grate machine 1, and then the material passed through the grate machine 1 is transported to the rotary kiln 2 for roasting, and then transported to the ring cooler 3 for cooling to obtain pellets;

[0098] 2) The hot air discharged from the ring cooling section C1 is transported to the rotary kiln 2, and the hot air discharged from the rotary kiln 2 is transported to the preheating second ...

Embodiment 2

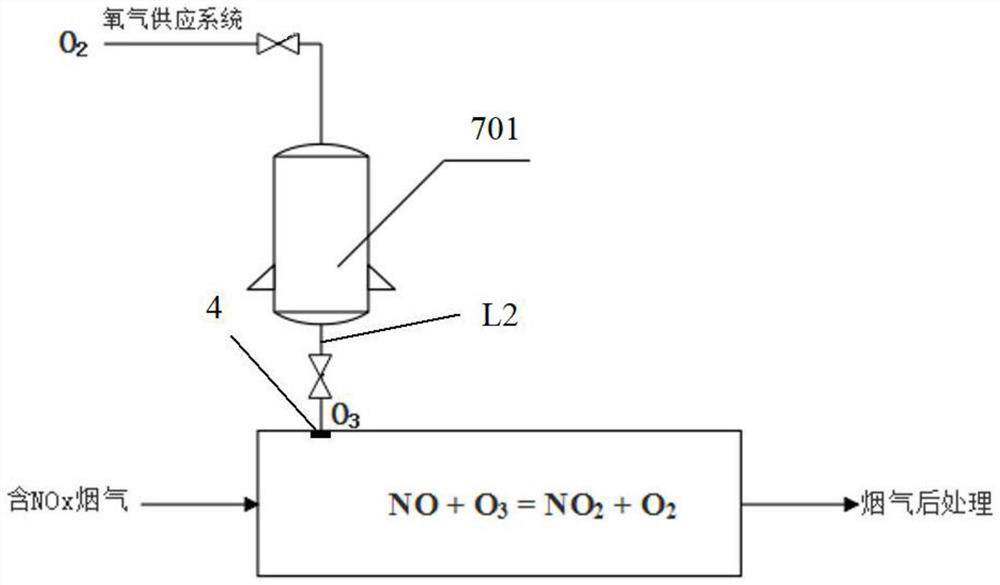

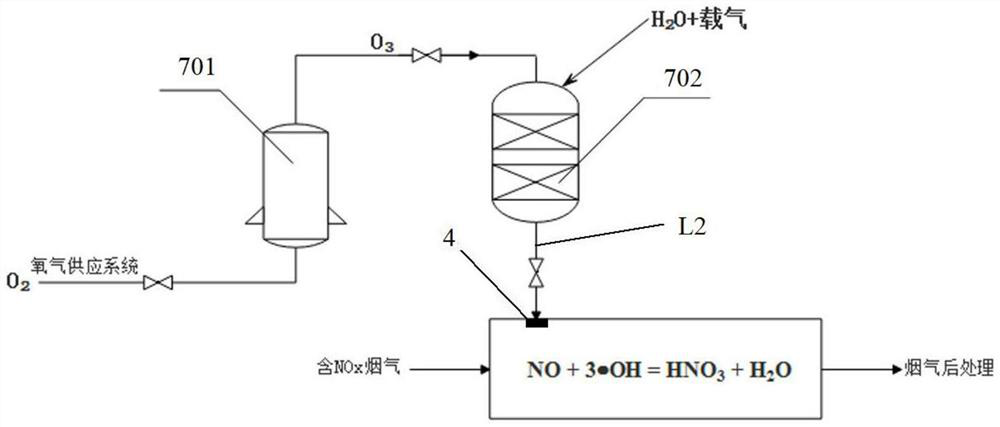

[0102] Example 1 was repeated, except that a denitrification device was installed in the bottom air box of the DDD of the draft drying section, and the denitrification device was an oxidant injector 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com