Thickness measuring temperature-controlled automatic adjustment air ring

An automatic adjustment and air ring technology, which is applied in the field of automatic adjustment of the air ring for thickness measurement and temperature control, can solve problems such as large thickness measurement error, and achieve the effects of low manufacturing cost, simplified air volume adjustment structure and uniform film thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

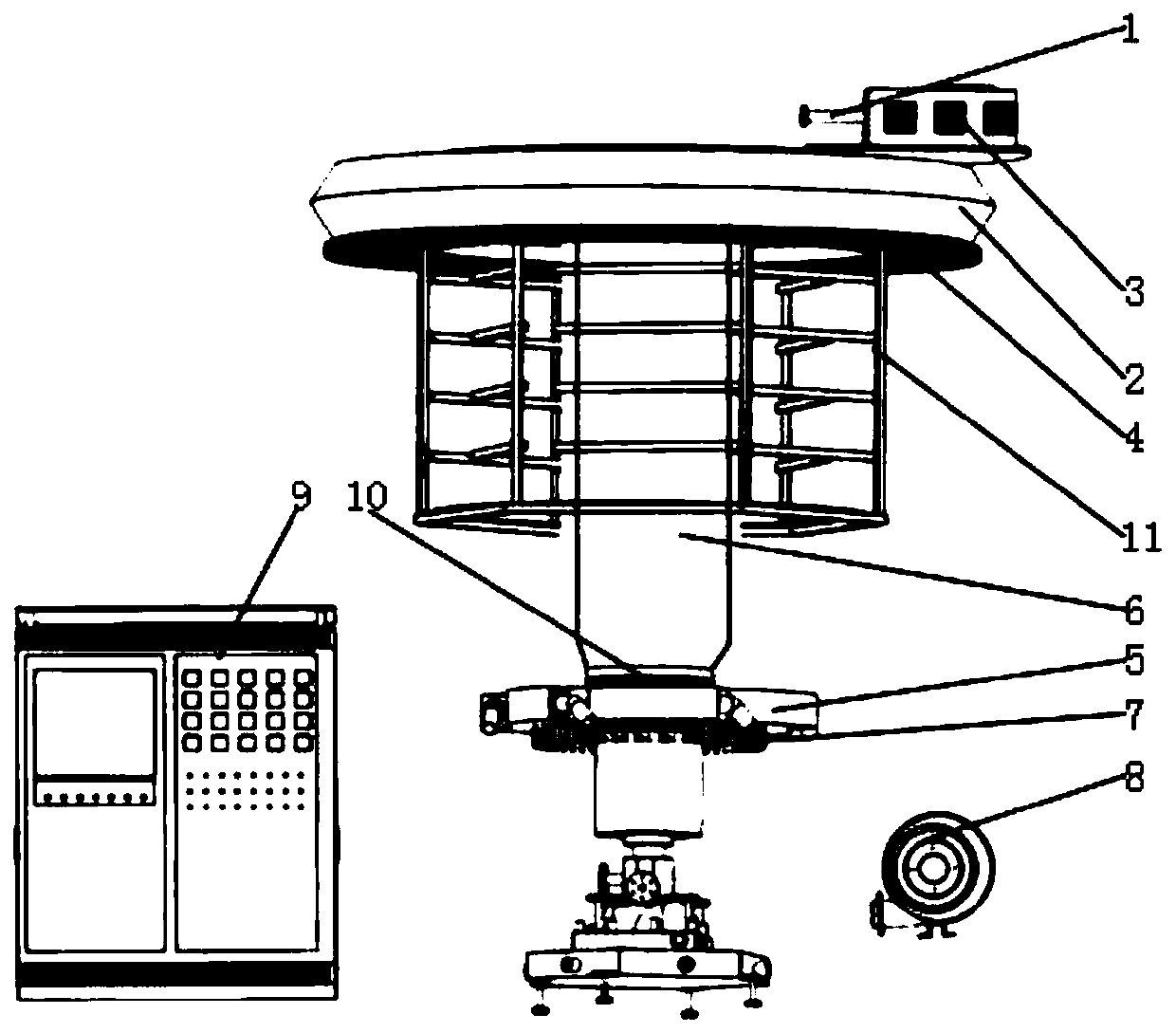

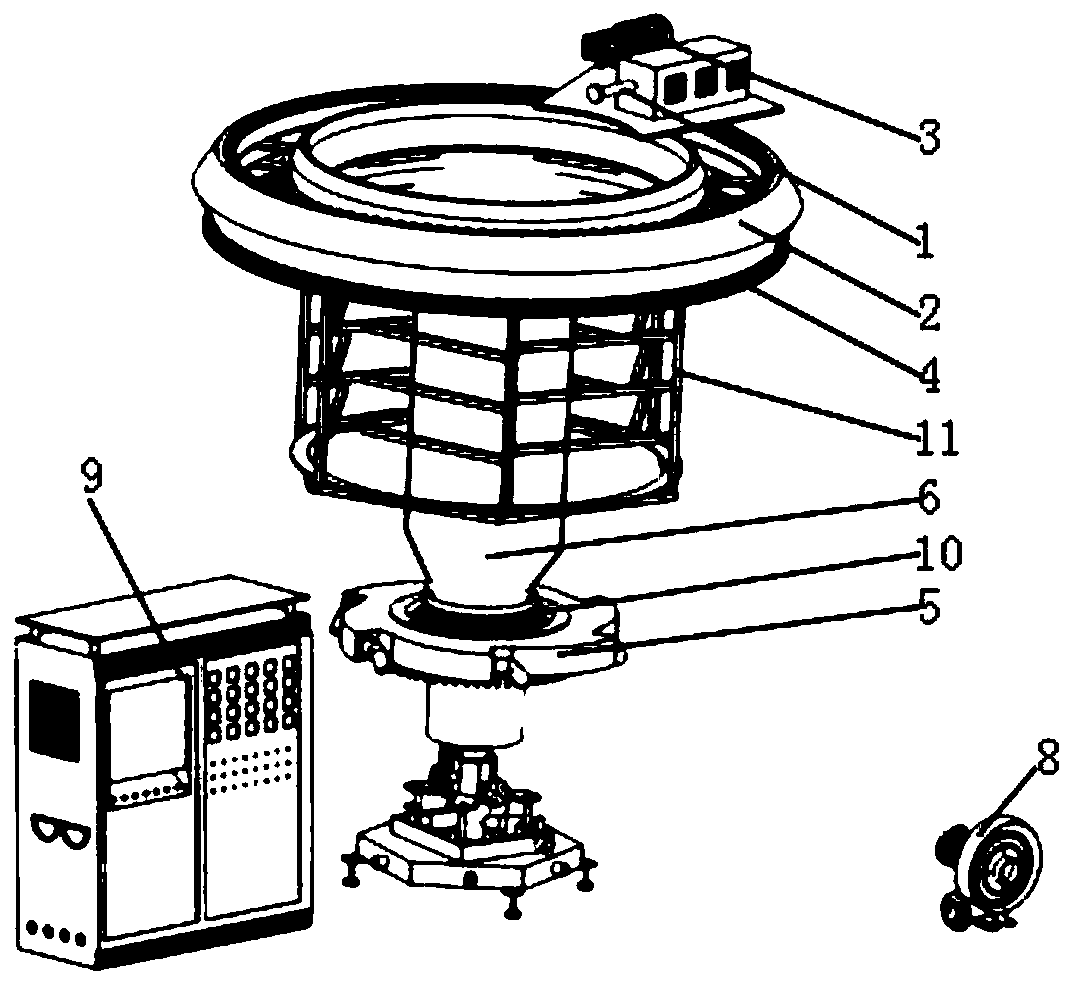

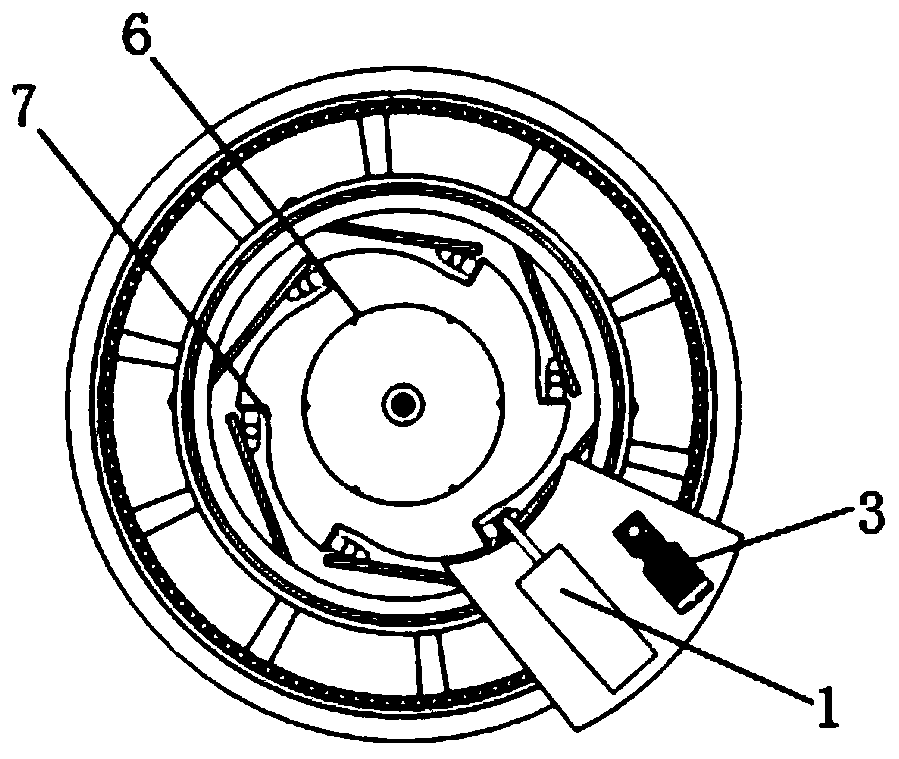

[0021] see Figure 1-3 , an automatic adjustment air ring for thickness measurement and temperature control, including a capacitance probe 1, a rotating track 2, a rotating motor 3, a rotating carbon brush 4, an automatic temperature control air ring 5, a film bubble 6, a heating rod 7, a fan 8, and an electric control Cabinet 9, mold 10 and film bubble rack 11, the lower end of the capacitance probe 1 is fixedly connected with a rotating track 2, the capacitance probe 1 can monitor the thickness of the film online, and the rotating track 2 is made of an aluminum casting integral ring, which is processed by a CNC machine tool The rotary track 2 is equipped with a circumferential inner tooth slewing bearing tooth plate, which has a stable structure and is easy to maintain. There is a carbon brush on the copper sheet track below to supply the power supply of the thickness gauge. The upper end of the rotating track 2 is fixedly connected with a rotating motor 3, which rotates 360...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com